Sample Engineering Brief 1

advertisement

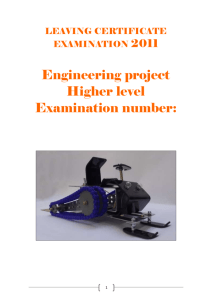

Introduction Design Brief Historically, the harsh winter climate of the Northern Hemisphere created challenges in the cross-country transportation of people and their possessions. In the late 19th Century this resulted in the invention of snowmobiles. Although originally developed as utility vehicles, advances in design and technology since then, have provided manufacturers with the scope to produce a full range of recreational, special purpose and competition versions of the snowmobile. Design a model of a snowmobile to the general specifications outlined. The model should: (a) Have the rear propulsion unit controlled by an ON/OFF switch; (b) Incorporate front skis with a steering mechanism; (c) Have seating capacity for the driver only. Special Note: Toys or modified toys are not acceptable. Presentation of the completed model should ensure that: (a) All main operating features are clearly visible without dismantling. (b) The longest dimension of the device does not exceed 300 mm. (c) Electronic power does not exceed 9 volts. Analysis of Brief Definitions Snowmobile: A land vehicle for winter transport on snow. Model: A miniature representation of an object. Steering Mechanism: A system of parts by which something is steered. Rear Propulsion: A drive mechanism positioned at the back of the snowmobile. Skis: A pair of narrow pieces of material used for transport on snow. Incorporate: Merge with something already in existence. Observations of the brief From the given brief, I understand that the snowmobile must include a number of factors: It must be controlled by an on/off switch. It must not exceed 300mm in any dimension. Not have electronic power exceeding 9 volts. The skis must be placed at the front and must be included in the steering. The tracks/rear propulsion mechanism must be at the rear of the model. There must only be enough seating room for a driver. All operating features should be visible without dismantling. Toys cannot be used. (All work must be my own) These factors set up the boundaries and limitations of the design of this project and show clearly what must be achieved. My Knowledge of Snowmobiles Snowmobiles are currently very popular in sport all over the world, although they were originally developed for transport in snowy/icy areas. Snowmobiles typically use a track system as the propulsion mechanism as they work very well offroad and are extremely durable. Tracks are used for their reliability and efficiency. However, alternate forms of rear propulsion are also available in snowmobiles, such as helical screws or fan based transport. From what I know, all snowmobiles use skis, as this is what defines a snowmobile. The skis generally provide directional control. Snowmobiles are very similar to all terrain vehicles, as they are not fully enclosed, other than the windscreen. The design of a model snowmobile should increase my knowledge of snowmobiles and their operation. Investigation of Solutions Propulsion As mentioned before, snowmobiles are not only confined to using a track mechanism, this allows a lot of room for variety in the construction of this project. This made the topic of snowmobiles far more expansive than I had originally thought. Tracks The track mechanism is by far the most popular in the range of possible solutions. The type of track mechanism also varies; they generally consist of one drive roller, and two driven rollers. These rollers can be gears, which hold onto track, or chain very efficiently, although from what I have seen these are not very common in commercial snowmobiles. A more tank-like propulsion mechanism, the most popular type of propulsion found in snowmobiles. Tracks are efficient and reliable, and most importantly, all terain. Helical Screws Helical screws are also used as a means of propulsion in snowmobiles, although they are far rarer than the track snowmobiles. They are designed to cope with difficult snow and ice, one screw rotates clockwise, and the other anti-clockwise, allowing the vehicle to move forward. The principal of operation is the opposite of a screw conveyor; the snow remains stationary while the machine itself moves. These machines can also be designed to run on water, making this an amphibious craft. Fans Snowmobiles can also be propelled by fans; this allows the snowmobile to potentially have more stability, as a tripod with a single ski at the front is more stable than a single track at the rear. Fan snowmobiles generally have a cockpit, allowing for a more secure and comfortable journey through the snow. Where they lack in speed, they make up for in comfort in potentially freezing conditions. Here are some images of other varieties of snowmobiles: Turning Mechanism As with the propulsion mechanism there are many different mechanisms to choose from, for the turning of your vehicle. Rack and Pinion Rack and pinion steering is the most common form of steering in cars. It converts the rotational motion from the steering wheel/handle bars into linear motion. A circular pinion is rotated which moves the rack left and right. This moves the tie rods, which in turn, turn the car. Rack and pinion steering would work very well for the snowmobile. Bevel gears Bevel gears are designed to convert rotational motion into rotational motion on an axis at 90 degrees. The simplicity of a steering mechanism derived from bevel gears makes them very appealing. Steering by means of bevel gears are not nearly as common as a rack and pinion steering, but may be just as efficient for what I want to achieve with my project. Skis From what I have seen, the skis on nearly every snowmobile are very similar. They all have a support strut looping from the front of the ski back to the top surface of the ski. I believe that this must be taken into consideration in the design on the snowmobile. It is an important part of the ski structure and is possibly necessary for the safety of the driver. Although most skis look very similar, there are specialised skis for powder snow. These skis must be wider to keep you on top of the powder. Other skis are designed to allow maximum flexibility to reduce the chance of malfunction, such as the implementation of independently pivoting and flexing rails which are on the same axis side by side. An ankle joint can also be seen here to give the ski more flexibility over uneven snow and terrain, I believe this is another important feature in skis. Criteria for Selection of Solutions After researching the options that I had thoroughly, along with benefits and errors, I decided to implement the following pieces and mechanisms into my project: (1) A track mechanism as the means of propulsion. (2) A bevel gear turning mechanism. (3) Skis similar to the design of most snowmobiles. (4) A seat for the driver, suitable for a snowmobile. (5) Ankle joints to give the skis more mobility and efficiency. (1) A Track Mechanism as the Means of Propulsion: I chose tracks as the means of propulsion because I believe it to be the optimum propulsion mechanism out of my choices. It is more of a challenge to use tracks than a fan or gear and chain; I believe it is also more reliable than the helical screw. Although tracks are an unoriginal idea, they are very flexible in their design; this ensures that no two track mechanisms will be the same. The flexibility of tracks makes this mechanism very appealing to me, and I have never dealt with tracks before, which would increase my skills and knowledge in the area. I also believe that the track mechanism adds to the aesthetics. (2) A Bevel Gear Turning Mechanism: I believe that bevel gears are a simple yet efficient means of turning the vehicle. The mechanism itself is quite simple; the bevel gears allow a 90 degree transfer of rotational to rotational motion. This means that the handlebars can have a realistic rotational movement, causing a small amount of rotation in the skis, similar to the turning in actual snowmobiles. (3) Skis Similar to the Design of Most Snowmobiles: As I’ve said before, nearly all snowmobiles have very similar skis. This proves that it is a tried and tested design, which works very well for snowmobiles. It is because of this fact that I felt it was necessary to stay true to this design and use the “loop” found on these skis in my design. I believe that these skis also greatly add to the aesthetics of the vehicle as a whole, and are far more appealing than a conventional ski that you would use for skiing. (4) A Seat for the Driver, Suitable for a Snowmobile: The seat on a snowmobile is very similar to the seat on a motorcycle. They are a cushioned saddle like seat, designed for both comfort, and performance. They do not have backs on the seats, as, like a motorcycle, the driver must lean forward to drive the snowmobile. I decided to design a seat which would give the driver full control over the vehicle, and comfort. (5) Ankle Joints to Give the Skis More Mobility and Efficiency: I decided to put ankle joints onto my skis, as I believe they are very necessary for the snowmobile to function correctly. These ankle joints give the skis a pivot point where they manoeuvre over bumpy or rough terrain. This prevents breakages in the skis, which greatly adds to the safety of the snowmobile. These ankle joints also increase stability and give the snowmobile a smoother ride. Ankle Joint Manufacturing Processes Track Mechanism The track mechanism is composed of 4 main sections: 3 roller assemblies to hold the tracks, and the central assembly to hold all of the rollers in place. Each section is made of multiple parts. Each roller consists of 2 aluminium wheels: which rotate so that the tracks can move; and a static acetal piece: which is used to connect the rollers to the central assembly and space the aluminium apart for the track width. The central assembly is made up of a horizontal cross bar to connect the two bottom rollers, and a spring loaded vertical cylinder to hold the top roller, and keep tension on the tracks. With this design I attempted to stay true to the type of track mechanisms found in snowmobiles. Above is a 3D drawing of the track assembly. I made the acetal pieces from a 30mm diameter bar which I turned down to 25mm diameter. I then cut the bar in 3 segments 20mm in length. Using the lathe I drilled a 4mm diameter hole through each piece. For the two bottom rollers I used the milling machine to cut the slots where bolts hold the pieces to the crossbar (a 3mm diameter hole was then drilled into this slot for the bolts) and the rectangular slot to house the crossbar. The other slot going around these pieces is 2mm thick and is necessary for the tracks to slot into it. This was also cut out on the milling machine. When acetal is machined a lot of swarf accumulates around the cuts, I filed down this swarf after machining. Two aluminium wheels are part of each roller, this makes a total of six aluminium wheels, because of this I decided to use the CNC machine. I made 6 aluminium billets and input a programme into the CNC machine to cut out the pieces I wanted. As the aluminium had to be held in a chuck, I had to face off the excess material. The completed aluminium pieces are 31mm outside diameter (2mm wide) and 30mm inside diameter (5mm wide). Each also has a threaded M4 hole. Above is a 3D drawing of a bottom roller. The top roller is very similar to the bottom rollers, the only difference being the acetal piece. Rather than the rectangular slot for the crossbar, it has a threaded M4 hole (the bar which compresses the tension spring is held here) and the 2mm slot for the tracks goes further around the piece. The top roller is not securely bolted in place, but the tension spring and the tracks keep it in the correct position. To drill the 4mm diameter hole on the curve I first used the milling machine to make a flat surface, and then used the tower drill to drill the hole. Above is a 3D drawing of the top roller. The central assembly supports all of the rollers and holds them firmly in place. The crossbar is 3mm thick aluminium which is 110mm x 20mm. I drilled an 8mm diameter hole 35mm down the centre line, to hold the cylinder which holds the spring. I also drilled two 4mm diameter holes 25mm from the other end and out 5mm from the centre line on each side; these holes hold the piece which holds the chassis to the snowmobile. I filed down the corners of the rectangle to prevent them from hitting the aluminium wheels. I made the cylinder from 15mm diameter aluminium which is 32mm long. I threaded a hole M8 6mm in from the bottom to secure the cylinder to the crossbar. I then drilled a 4mm diameter hole in the top of the piece 22mm long, using the lathe. This is the hole for the spring. To make the tension mechanism work, I used a 4mm diameter bar and cut it to be 42mm long (so that the tracks would fit around every roller). I turned the end 4mm of the bar down to 3mm diameter so that the bar would partially fit inside the spring. The other end was then threaded M4 and connected to the top roller. This tension mechanism holds the top roller in place, and makes sure there is never too much slack on the tracks. Above is a 3D drawing of the crossbar and tension mechanism. Above is an exploded view of the full track mechanism.