Ch01.DOC

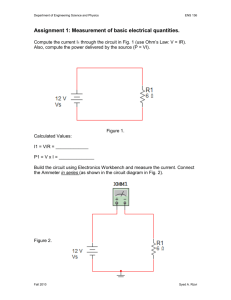

advertisement