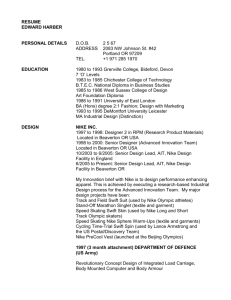

Nike write-up Outline - Applicant seeking PhD in Marketing :: Monte

advertisement

Outsourcing From South Korea To Vietnam December 13, 2005 Joe Atkin Stacy Giauque Monte Shaffer Rich Smith Outsourcing: From South Korea To Vietnam Page 1 of 12 INTRODUCTION Nike has always had a global presence in the ‘outsourcing’ of its shoe manufacturing throughout the world. This paper will discuss Nike’s beginnings with founder Phil Knight, its core strategy as it relates to globalization and its marketing strategy. From there, we will discuss rational for Nike to move from country to country in the East. This tradition was published by Jardine Fleming as the Nike index. From the implications of the Nike Index we will look at factors that may determine why Nike is currently in certain countries. To conclude, we will discuss the cultural implications of moving factories from South Korea to Vietnam, the effects of South Korean expatriates in Vietnam, and how Nike has tried to address these issue. PHIL KNIGHT IS NIKE As the largest sportswear retailer in the world, Nike began as the brainchild of controversial but ever-passionate Phil Knight. As he epitomizes the Nike approach to sportswear marketing, Phil Knight has always been considered a free-spirited and resourceful competitor. In 1959, he graduated from the University of Oregon, receiving his undergraduate degree in accounting. He was a middledistance-runner for the Oregon Ducks, running a 4:10 mile. In 1962, he earned his MBA from Stanford, developing a strategy to build a business around sports shoes. One term paper – “Can Japanese Sports Shoes do to German Sports Shoes what Japanese Cameras did to German Cameras?” – described a “you're-crazy-it-will-neverwork- or-someone-would-already-be-doing-it” idea about bringing low-priced, high-tech athletic shoes from Japan to dislodge German domination of the U.S. athletic footwear industry. From this term-paper, Phil Knight established the Nike business model: “We don’t sell shoes we sell sports fashion.” Nike has always outsourced manufacturing. In light of Nike’s model that focuses on sourcing from low cost manufacturers, the purpose of this paper is to outline the strategic process Nike undergoes when selecting markets from which to outsource and the process of moving outsourcing operations from various countries throughout Asia. More specifically, this paper will address the strategic implications that result from these moves, with specific emphasis on Nike’s outsourcing shift from South Korea to Vietnam. MARKETING AS NIKE’S CORE COMPETENCY Nike is a marketing company. Nike is not a manufacturing company. “Global and transnational capitalism has brought with it industries where commodities are themselves symbols. No firm better fits this model than Nike whose symbolic capital has acquired a huge global reach. The primary vehicle through which Nike has built its cultural icon and its symbolic capital has been its advertising and sports marketing.”i Outsourcing: From South Korea To Vietnam Page 2 of 12 According to US Business Week in 2005, Nike is ranked 30th in brand recognition with an estimated $10.1 billion in brand value. CEO Phil Knight boasts of Nike’s success model: “For years, we thought of ourselves as a production-oriented company, meaning we put all our emphasis on designing and manufacturing the product. But now we understand that the most important thing we do is market the product. We've come around come around to saying that Nike is a marketing oriented company and the product is our most important marketing tool.”ii In support of Nike’s position as a company with one of the largest marketing budgets, Nike has succeeded in reaching top rank as the world leader in tennis shoe and sportswear sales. A major percentage of Nike’s marketing dollar is spent on celebrity endorsement including multi million dollar contracts signed by athletic demi-gods Michael Jordon and Tiger Woods. In 2000, Tiger Woods signed a five-year $100 million contract to represent Nike. In spite of highly capitalized strategic marketing know-how, the company’s underlying success is dually-attributable to a scrupulous and tactical outsourcing strategy. This strategy has typically removed Nike from the risks involved in light manufacturing of shoes and sports apparel in foreign countries. This outsourcing model is the primary topic of this paper. RELATIONSHIPS WITH OUTSOURCED SUPPLIERS As of April 2005iii, Nike has reported that 703 factories are producing their “Nike branded finished products” in 52iv countries around the world, including the United States. All of these factories are outsourced manufacturing vendors; Nike does not own any part of any of these factories. Fifteen countries contain about 80% of all Nike factories; 60% of all Nike factories are located in Asia, and 32% specifically in S.E. Asia. The reduction from 850 factories in 1998 to 703 factories today is best explained by the phasing out of the WTO quota system called the Agreement on Textiles and Clothing (ATC)v. Outsourcing: From South Korea To Vietnam Page 3 of 12 Top 15 Countries CHINA THAILAND USA INDONESIA KOREA VIETNAM MALAYSIA TURKEY SRI LANKA JAPAN MEXICO PORTUGAL TAIWAN BRAZIL INDIA 0 25 50 75 100 125 Nike has been committed to creating long-term relationships with its suppliers, with attempts to maintain exclusivity. Yue Yuen Industrial Holdings, Ltd. is an example of one such vendor that has worked with Nike for many years, although its relationship is by no means exclusive. Today, Yue Yuen is the largest manufacturer of shoes in the world supplying both Nike and Reebok. One manager from the company was quoted in the Wall Street Journal to say that Yue Yuen’s annual profits are higher than its buyers (Nike’s or Reebok’s) profitsvi. It’s not surprising that Goldman Sach’s has invested heavily in this supplier. In 2001, it was reported that “37 out of its 40 current footwear suppliers manufacture 100% Nike product. This prevents competitors seeing new Nike shoes coming down the line, or learning how Nike makes its shoes.”vii Nike factories produce much more than footwear today, but it evident that a small cluster of factories produce most of its shoes. The overall driver for maintaining relationships with shoe factories in a region was their ability to deliver quality: Nike had a worldwide policy that its B-grade shoes could not constitute more than 5% of supplier’s total production during the first year, and 3% thereafter. Bgrade shoes had cosmetic defects but were structurally sound. [C-grade shoes had to be destroyed to prevent brand erosion.] viii In 1997, a Hong Kong-based financial group named Jardine Fleming International Securities Ltd. released a report Tracking Nike’s Footprints Across Asia describing the trends of Nike factory movements. This report coined a predictive index, named the Nike Index, which describes factors that determines when and why Nike will leave a country and how the determine a new location for factories. This index gives credible insight as to the metrics Nike evaluates when selecting markets from which to outsource. Outsourcing: From South Korea To Vietnam Page 4 of 12 Long-term relationships with original suppliers from South Korea and Taiwan (when Blue Ribbon Sports became Nike) have defined Nike’s outsourcing model: as wages rose in these developing countries, Nike suggested that these major suppliers move to other countries, as described by former Nike VP Neal Lauridsen: We say "We're in a position to give you 'x' amount of orders" to take the uncertainty out of the move. They go to the country. They bring management. That formula has worked really wellix. Nike’s relationships with its suppliers were strong in 1990, and today are even stronger. Most financial analysts identify eight major suppliers that are involved in much of the production of Nike ‘shoe’ products in Asia. Over the past 15 years, these companies have established operations in several low-cost labor locations. Flexibility has been refined through the years of learning and experience. Not only can they quickly adjust to market demands of a specific Nike shoe model, they have also learned how to quickly open and close factories in given countries based on economic predictors. Opening a large factory in the low-tech, intensive-labor manufacturing process is as simple as renting a warehouse and bring in sewing machines. Raw materials and labor costs are bigger concerns than the factory location and facility management. This was exemplified in the early 1990’s when South Korea was rapidly vacated—over 380,000 employeesx lost their job in Pusan, South Korea as Nike encouraged suppliers to go elsewhere as daily wages rose from $9.71 per day in 1986 to $24.40 in 1990. South Korean and Taiwanese suppliers relocated where Nike asked them too—at this time, the move consisted of setting up new shops mostly in Vietnam and Indonesia. China was also pursued as an option, but bureaucratic barriers and poor production quality made China a difficult entry, especially for Taiwanese and South Korean companiesxi. NIKE INDEX The Nike Indexxii described all economic and political factors related to the factory moves: Large pool of available labor. [Measured through several sub factors: country’s unemployment rate, % of agricultural/rural workers, labor force participation potential among female workers.] Cheap labor [Not only cheaper relative to other countries, but agricultural/rural labor is cheaper than urban labor.] Developing country [Measured by current GDP per capita and reinvestment of GDP into country’s infrastructure] Governments that are pro-business and have liberal trade regimes. Stable governments (usually authoritarian in nature—e.g., Indonesian dictator Suharto—which limits the ability for workers to unionize) Outsourcing: From South Korea To Vietnam Page 5 of 12 This index can even be applied within a country as demonstrated by closures of factories in highly regulated provinces of China (Shanghai and Tianjin) and opening factories in Guangzhou (similar in culture/distance to Vietnam) and Fujian (rural area close to Taiwan). These new areas had fewer regulations and restrictions which made them more appealing. Further, they were physically close to Vietnam and Taiwan, which was obviously beneficial to both South Korean and Taiwanese suppliers. Analyzing Nike’s current choice for factory locations for shoes, apparel, and other products, it is evident that economic factors are considered when positioning a factory. As seen below, data including available rural labor and GDP Reinvestment suggests why China is currently an ideal location for factories and product manufacturing: Number of Country Factories INDIA 18 BRAZIL 18 TAIWAN 19 PORTUGAL 20 MEXICO 20 JAPAN 22 SRI LANKA 25 TURKEY 26 MALAYSIA 33 VIETNAM 34 KOREA 35 INDONESIA 39 USA 49 THAILAND 73 CHINA 124 Labor Force 482.2 89.0 10.2 5.5 34.7 67.0 7.3 25.3 10.5 43.0 22.9 111.5 147.4 36.4 760.8 Current Unemployment 9.2 11.5 4.5 6.5 3.2 4.7 7.8 9.3 3.0 1.9 3.6 9.2 5.5 1.5 9.8 Agricultural Percentage 60.0 20.0 8.0 10.0 18.0 5.0 38.0 35.9 14.5 63.0 8.0 45.0 0.7 49.0 49.0 Per capital GDP GDP Reinvestment (%) $3,100 23.8 $8,100 19.8 $25,300 18.0 $17,900 22.3 $9,600 19.4 $29,400 24.0 $4,000 22.4 $7,400 17.3 $9,700 21.7 $2,700 36.6 $19,200 28.7 $3,500 16.6 $40,100 15.7 $8,100 22.5 $5,600 46.0 Outsourcing: From South Korea To Vietnam Page 6 of 12 This data was collected from the CIA World Factbook and in some ways is datedxiii; however, these indicators show some economic evidence that correlates to the Nike Index. As will be discussed specifically in the Vietnam instance, and as was alluded to above, there are major cultural implications of having expatriates from Taiwan and South Korea manage workers in Vietnam, Indonesia, and China. OUTSOURCING RELOCATION FROM SOUTH KOREA TO VIETNAM Naturally there are strategic implications of each of Nike’s sourced relationships in Asia; however the remainder of this paper will focus on South Korean manufacturers’ move to Vietnam. The actual decision for South Korean manufacturers to move Nike-sourced shoe and apparel production specifically to Vietnam as opposed to another S.E. Asian location was risky, although still highly calculated, as described by Phil Knight in 1998: So when we saw the need for advanced production going to Southeast Asia, one of the most adventurous things that we did was decide to make shoes in Vietnam, which is an area that has had a lot of observation and criticism over this last couple of years. It is a grand and bold adventure, and there are a lot of aspects of it that I believe that you have not heard. […] There was no existing shoe industry. So essentially, if we were going to make it work, we would once again have to take our Taiwan and Korean managers with us. There were two problems with that. First of all, foreign owned factories by law in Vietnam must pay a minimum wage 50% higher than Vietnamese owned factories. So if we were successful, we would then in turn create a shoe industry in which our competitors would be able to come in and start their businesses with Vietnamese owned factories and have a competitive advantage. The second thing, of course, is very simplistic, but it's true. There was truly historical hatred between the two ethnic groups which would go in there and manage those factories in Vietnam. But we did it anyway. A couple months ago I had dinner with my friend David Halberstam who's had quite an experience out in Vietnam as well. When we told him that we were using Korean and Taiwanese managers in Vietnam, his comment was simple: "How could you have been so stupid?" But the flip side is equally simple: No Koreans and Taiwanese; no Vietnamese shoe industry. And for all you have read, Nike shoes make up 5% of the total export of the whole nation of Vietnam. So we contribute on two counts: to give jobs and to generate a significant amount of foreign currency. But there are, with all of that, lots of problems. The management of the Vietnamese work force by foreign managers has complicated the whole process, and it has come under a great spotlight […] We have about 530,000 workers working on Nike shoes and clothes on a given day. There are going to be incidents. There have been some in the past, and there certainly will be more in the future. There are too many workers, too many interactions daily; and in Vietnam, too much tension based on nationality to avoid any incidents. That there have been as few as you have read about I think in many ways is remarkable.xiv Outsourcing: From South Korea To Vietnam Page 7 of 12 Based in Ho Chi Minh City, in 2001, Nike’s Vietnamese operations consisted of 43,000 workers making 22 million shoes annually and exporting income of $450 million. “Nike production accounts for 8 percent of Vietnam’s manufactured exports and 32 percent of its footwear exports.”xv In 2001, of Nike’s 850 supplier factories worldwide, 5 footwear and 7 apparel factories are located in Vietnam. Outside of agricultural production, Nike is the single largest employer in Vietnam with 46,000 workersxvi. Based on Jardine-Fleming Index factors discussed above, Nike’s pressure towards South Korean suppliers to move operations to Vietnam was not solely economically driven. It is often argued that globalisation of production means that the developing world is highly vulnerable to decisions in the developed world to shift production contracts from country to country in the search for ever cheaper labour rates and poorer conditions. This is the so-called race to the bottom.xvii Even while decreases in labor costs shifted from Japan to South Korea to Southeast Asian markets, Nike was systematically weighing index consideration. Index factors that justified the move to Vietnam were not solely limited to Vietnam’s lower labor costs, burgeoning economy or an industrious and quality oriented work force. Vietnam’s gradual shift from primary agricultural markets to light manufacturing was critical to Nike’s decision. Concurrently, as Vietnam experienced drastic increases in women’s labor force participation rates, Nike encouraged manufacturers to relocate to Vietnam. Another key driver that initially drove Nike to move beyond other Asian markets including China and Indonesia was the quality issue. In general, shoe manufacturing in Vietnam focused more on quality intensive products like sportswear and tennis shoes. China, on the other hand, supplied a wide variety of shoes with varying degrees of quality and labor intensity, products not always exclusive to the sportswear industry. Another factor that positioned Vietnam as a viable sourcing location is the fact that it is a country with less risk for copyright infringement and exposure to mass distribution of imitation products than neighboring China. As Vietnam experiences lower rates of capital inflow, Nike had less concern for sourced Vietnamese suppliers to overturn barriers to entry and start their own private retailing business. Whereas operations in Macau, Hong Kong, or Beijing left Nike susceptible to lax copyright protection and excess supply of lower quality, lower cost overflows from mass production. Outsourcing: From South Korea To Vietnam Page 8 of 12 Although Nike’s interest in sourcing from Vietnam was not solely cost driven, low labor wages were definitely a consideration. In 1997 Vietnamese employees earned between $32-$45 a month or about $1 a day on average. Compared with rising costs in South Korea that compensated Nike-sourced employees at $24.40 per day in 1990, the cost benefit of moving lowend manufacturing with minimal capital outlay to Vietnam becomes very obvious. Nike’s 1995 move to Vietnam marked a significant evolution in the company’s approach to global labor issues. The shift in outsourcing actually signaled a new beginning in Nike’s attitude towards supporting higher labor standards. Historically targeted as the evil exploiter of low wage labor, Nike had been highly scrutinized for their operations in Indonesia, as well as other emerging Asian markets. Based on a USAID funded survey, Nike endured criticism as the culprit for low wage compensation violations, child labor exploitation, and overworking sourced employees. In 1998, CEO Phil Knight accepted responsibility for low level labor standards and implemented six initiatives for the firm including expanding worker education programs, involving NGO’s in factory monitoring, and funding university research and forums to educate on global relations issues. Later after Nike got burned in 1996 and 1997, the move to Vietnam also constituted a strategic PR repositioning and an opportunity for Nike to clean up tainted consumer perceptions of other operational exploitation in Asia’s low wage labor market. As a sporting goods marketing giant, Nike has been able to leverage bargaining agreements in Vietnam to their advantage. Because of their muscle as a large US firm, Nike is able to require Vietnamese manufacturers, including those managed by South Koreans, to align with their new socially responsible labor practices. Nike required sourced Vietnamese manufacturers to agree to, pay for, and undergo a pre-sourcing audit conducted by a third party. Additionally, Vietnamese plants are required to undergo Nike directed audits four times per year. Although these controls and audits paint Nike as a socially responsible outsourcer, realistically, the primary reason Nike implemented these labor standard reforms is because of pressure and litigation from labor activist groups. Despite years of experience outsourcing from other Asian markets, Nike encountered strong barriers of integration when they moved sourced manufacturing from South Korea to Vietnam. Naturally there are major cultural and compensation issues that are beyond the limited scope of this paper. However a discussion of Nike’s outsourcing challenges and shortcomings cannot be overlooked. The major global management challenges include, but are not limited to, cultural, language, economic, and logistical differences. In 1997, Nike asked Andrew Young, a labor consultant to evaluate and provide recommendations of how to overcome drastic cultural barriers that hindered productivity. The greatest cultural gap Nike had to bridge, manifested in the way South Korean managers related to Vietnamese employees, consists of the following factors: On the most basic level, there are wide language difference between South Korean Managers and Vietnamese employees. South Korean supervisors managed Vietnamese workers according to their home standards, rather than by cultural standards indigenous to Vietnam Outsourcing: From South Korea To Vietnam Page 9 of 12 Vietnamese employees were accustomed to rural, non-technical, self-paced agricultural work routine. Vietnamese employees struggled to adjust to a more regimented factory routine. Typically, Vietnamese workers did not have a great deal of formal education and therefore were not aware of their basic rights as workers. In response to the cultural and language barriers that divided South Korean managers and Vietnamese workers, Nike implemented special human relations and cultural sensitivity programs. Specifically, Nike raised manufacturing standards by introducing an after-hours education program that fostered idea generation and integration into factory life. Employees benefited from after-hours classes that were co-sponsored by Nike and the Ministry of Education. Nike also introduced the Nike Jobs and Micro-enterprise Program which provided economic support through micro-loans to women in the communities surrounding its suppliers. Perhaps the most integral program Nike implemented to overcome culture barriers and foster integration between South Korean managers and Vietnamese workers was the Cultural Sensitivity Training Program. This program trained South Korean managers on the cultural differences between their home and host countries. CONCLUSION Moving forward, Nike is taking initiatives to improve its impact on developing countries as described by Dusty Kidd, VP of Corporate Social Responsibility: The strategic concept for Nike entering the new century is to be an archetype of the responsible 21st century global company, in the sense that we are providing a sustainable footprint everywhere, not only with environmental performance, but with people performance as well. The triple bottom line of people, planet and profit is our goal. The dynamics of Nike’s relationships with its major suppliers may be a strategic issue in the future. Many of the outsourced manufacturers used by Nike have grown so large that the power gap between them and Nike has been minimized and may very well be on the verge of reversing. This may very well necessitate a change in strategy for the shoe giant, leading to a more traditional and equal handed buyer supplier relationship. Although Nike has a strong brand which keeps this relationship in check, the desire to not create joint-ventures with its suppliers may one day become a problem for Nike. CHINA THE FINAL FRONTIER? According to the Nike index, the indicators for a Nike move show both China and India as powerful options. A quick analysis of these indicators may shed some light on why China may be the most viable option. The Nike index cites a large available labor source as a strong indicator of a Nike move. More specifically, this indicator seeks a trend of rural labor moving Outsourcing: From South Korea To Vietnam Page 10 of 12 toward simple manufacturing. This requires a large rural labor force with a GDP per capita lower than that of more urbanized areas. In China this gap has been widening since the mid 80’s: The ratio of urban disposable income to rural net income increased from 1.86 in 1985 to 2.47 in 1997 to as much as 3.11 in 2002. There was a brief period (199597) during which these differences narrowed, but the divergence appears to have become sharper thereafter. Similarly, the ratio of urban-rural per capita consumption expenditure increased from 3.1 in 1997 to 3.7 in 2002, a much sharper rise than in the previous decade.xviii Although the GDP per capita for China is slightly higher at $5,600 than India at $3,100 there is a significant difference in government reinvestment: The cycle of increased public investments leading to greater capital goods industry growth was evident in the eighties in India, but with the level of public sector investment going down in reform period, there was an inevitable slowdown in capital goods industry. China did not allow such a decline, thanks to its investment in infrastructure through the public sector…It is sometimes argued that the decline in public investment in India in the post-reform period was made up by increase in private investment. This argument misses the qualitative difference in the two investments. Public sector investment was primarily in items, like railways, irrigation, power and roads, which had a tremendous spread effect and helped nurture many small and medium industriesxix. Such investments in infrastructure will be of great benefit to Nike as it searches to infiltrate these previously rural areas. Although Nike may have to rethink their manufacturing philosophies, China is positioned as the most probable location to take Nike into the future. Outsourcing: From South Korea To Vietnam Page 11 of 12 ENDNOTES i Nike Culture, The Sign of the Swoosh, pg. 168, Robert Goldman and Stephen Papson, Publisher Sage 1998 Phil Knight, last 1980's, NIKE: the 'Goddess of Marketing' ICMR. iii http://www.nike.com/nikebiz/nikebiz.jhtml?page=25&cat=activefactories [RAW data synthesized] iv SWITZERLAND, PERU, BELGIUM, NEW ZEALAND, CAMBODIA, MOLDOVA, MACEDONIA, DOMINICAN R, ECUADOR, LITHUANIA, FIJI, GREECE, GUATEMALA, ALBANIA, SINGAPORE, COLOMBIA, CHILE, JORDAN, MACAU, PAKISTAN, EGYPT, PHILIPPINES, MOROCCO, SPAIN, UK, BANGLADESH, ISRAEL, EL SALVADOR, SOUTH AFRIC, ARGENTINA, BULGARIA, HONDURAS, HONG KONG, TUNISIA, AUSTRALIA, CANADA, ITALY, INDIA, BRAZIL, TAIWAN, PORTUGAL, MEXICO, JAPAN, SRI LANKA, TURKEY, MALAYSIA, VIETNAM, KOREA, INDONESIA, USA, THAILAND, CHINA v http://www.wto.org/english/thewto_e/minist_e/min96_e/textiles.htm vi Email from Jeff Ballinger to Monte Shaffer (February 12, 2005) with a citation to DAILY EXPRESS NEWS (Sabah, E. Malaysia). Manufacturers in China sing Pearl River Delta blues. 20 June, 2004 vii http://www.new-academy.ac.uk/publications/keypublications/documents/nikereport.pdf viii HBS 390-092, page 8. ix HBS case 394189, page 4. x Competitors generally followed Nike’s pre-emptive moves, so these employment numbers also include employees producing shows for Reebok, etc. The ‘move out’ of South Korea was not a complete departure (120,000 jobs remained), but this move has had a major impact on the economy of South Korea. xi HBS Case 390092, pages 4-6. xii It is not surprising that the actual report is difficult to find (not even available via Inter Library Loan). References to this index are as follows: ii http://www.businessweek.com/1997/18/b352523.htm http://www.new-academy.ac.uk/publications/keypublications/documents/nikereport.pdf http://www.emergingmarkets.co.uk/html/Labour%20Intensive%20Manufacturing%20Industries%20Case%20Study.pdf The quality of the information is limited; however, Nike and its suppliers have indicators similar to these, and most likely, much more timely and accurate. xiv Phil Knights address at the National Press Club. May 12, 1998. xv Program Studies of Innovation in the Management of Global Labor Challenges, Nike Inc, Rising Above Sweatshops, pg. 149. xvi More than any other ‘foreign’ business. Ivey Case: 9A99C034, page 4 xvii http://www.new-academy.ac.uk/publications/keypublications/documents/nikereport.pdf xviii The real forces behind China’s rapid growth, C.P. Chandrasekhar, Jayati Ghosh; The Hindu Business line Internet addition. (http://www.thehindubusinessline.com/bline/2005/02/22/stories/2005022200250900.htm) xix S. Venkitaramanan (http://www.thehindubusinessline.com/bline/2005/06/06/stories/2005060600330800.htm) xiii Outsourcing: From South Korea To Vietnam Page 12 of 12