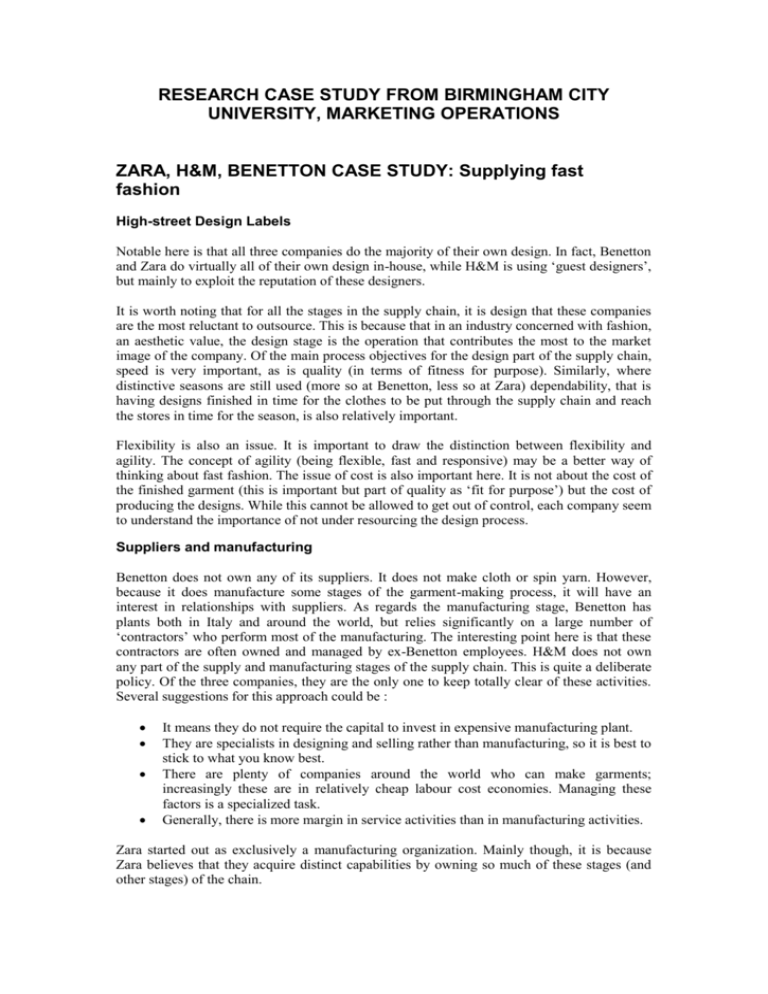

Zara, H&M, Benetton Supply Chain Case Study

advertisement

RESEARCH CASE STUDY FROM BIRMINGHAM CITY UNIVERSITY, MARKETING OPERATIONS ZARA, H&M, BENETTON CASE STUDY: Supplying fast fashion High-street Design Labels Notable here is that all three companies do the majority of their own design. In fact, Benetton and Zara do virtually all of their own design in-house, while H&M is using ‘guest designers’, but mainly to exploit the reputation of these designers. It is worth noting that for all the stages in the supply chain, it is design that these companies are the most reluctant to outsource. This is because that in an industry concerned with fashion, an aesthetic value, the design stage is the operation that contributes the most to the market image of the company. Of the main process objectives for the design part of the supply chain, speed is very important, as is quality (in terms of fitness for purpose). Similarly, where distinctive seasons are still used (more so at Benetton, less so at Zara) dependability, that is having designs finished in time for the clothes to be put through the supply chain and reach the stores in time for the season, is also relatively important. Flexibility is also an issue. It is important to draw the distinction between flexibility and agility. The concept of agility (being flexible, fast and responsive) may be a better way of thinking about fast fashion. The issue of cost is also important here. It is not about the cost of the finished garment (this is important but part of quality as ‘fit for purpose’) but the cost of producing the designs. While this cannot be allowed to get out of control, each company seem to understand the importance of not under resourcing the design process. Suppliers and manufacturing Benetton does not own any of its suppliers. It does not make cloth or spin yarn. However, because it does manufacture some stages of the garment-making process, it will have an interest in relationships with suppliers. As regards the manufacturing stage, Benetton has plants both in Italy and around the world, but relies significantly on a large number of ‘contractors’ who perform most of the manufacturing. The interesting point here is that these contractors are often owned and managed by ex-Benetton employees. H&M does not own any part of the supply and manufacturing stages of the supply chain. This is quite a deliberate policy. Of the three companies, they are the only one to keep totally clear of these activities. Several suggestions for this approach could be : It means they do not require the capital to invest in expensive manufacturing plant. They are specialists in designing and selling rather than manufacturing, so it is best to stick to what you know best. There are plenty of companies around the world who can make garments; increasingly these are in relatively cheap labour cost economies. Managing these factors is a specialized task. Generally, there is more margin in service activities than in manufacturing activities. Zara started out as exclusively a manufacturing organization. Mainly though, it is because Zara believes that they acquire distinct capabilities by owning so much of these stages (and other stages) of the chain. Distribution Very few companies of this type still perform all their own distribution. All three have warehouse facilities. In particular, Zara has put significant investment into warehousing probably to give an advantage in terms of speed. For fast fashion companies, increasingly a warehouse is not a storage place as such; it is rather a sorting operation, similar to a post office. Goods should not stay for long in the warehouse (if at all); rather, the warehouse is to split batches up and reassemble them for delivery to the retail stores. To that degree, it is an extension of the factory. The other part of distribution is the physical logistics of moving the goods around the world. This is part of any company that is most likely to be outsourced. All three companies outsource a very significant part of this activity. Retail Here we have a contrast between Benetton on the one hand (who own very few of their own retail stores) and H&M and Zara on the other hand (who own them all, except for partnerships in countries where this is a legal necessity). There are advantages of not owning your stores, but relying on franchising them instead. This is what Benetton does. The main advantage here is that the company can expand without investing too much of its own capital. So why have Zara and H&M chosen not to franchise at all? Overview of the three companies The main point here is that although all three companies are in (more or less) the same part of the market, they have chosen to organize themselves in somewhat different ways. One point here is that there is no obvious best answer in the design or management of supply chains. However, there are differences between the companies and these are reflected in the design chain choices they have made. Benetton can be seen primarily as a ‘brand’. This is supported by the nature of its clothes (the United Colours of Benetton), which is why it retains control over the design process. But apart from that its main concern is to establish the brand in the market by building on its image (hence the concentration on advertising, not entirely successful in every market). But the focus is always on the brand and the image. It does not therefore need total control of the rest of the supply chain in order to achieve this. All it needs is sufficient control through the factories that it does have and the stores and franchise agreements that it operates, to exert a guiding influence on the stores brand image. H&M is again primarily a design-led company, but one that has chosen to manage its market growth by investing in retail. This may be partly because H&M generally sells at a lower price point that Benetton. One would assume therefore that its margins are less. Therefore, it may wish to retain the entire retail margin for itself rather than give some of it to franchise holders. To an even greater extent than Benetton, it does not invest in between the design and the retail stages of the supply chain. In this it is similar to many other companies operating in this part of the market, Gap for example. Zara is the most interesting of the three in many ways. It has a far higher degree of vertical integration and it also has the fastest throughput time from design to retail store. These two facts are not unrelated. Zara focuses on speed through control. It believes that controlling a large part of the supply chain is the only way to guarantee very fast supply chain throughput. Also, because Zara produces a huge number of new designs every year (it is more likely to modify a garment or design it afresh than it is to repeat an order) it places even more emphasis on the need to control the total throughput.