15 - Indian Railways Institute of Mechanical and Electrical Engineering

advertisement

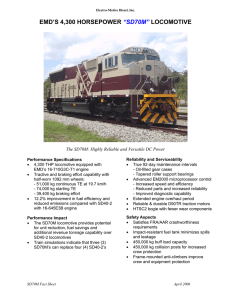

15. Locomotive Testing And Painting 15.1 Locomotive Test General Motors adheres to following concept/philosophy: All individual assemblies and components are tested during the locomotive assembly either at the GM works or at the supplier end. All electronic and air brake equipment are to be left unplugged during assembly. 15.2 Testing should verify/ audit integration of all locomotive system and sub-system. A very elaborate test procedure for the complete locomotive is followed by EMD before the locomotive is put on line. The test procedure is based on the relevant Engineering Test Instructions, defects found on previous units and reports from the service department. In case of GT46MAC, which would be a prototype even as it is electrically similar to SD70MAC, the procedure for the first locomotive is a more exhaustive and stringent test protocol. After completion of testing, the test records are scrutinised. As test checks are completed or at the end of the shift, they are to be initialled by the test personnel opposite to the test numbers. After the preliminary inspection, Hi Pot Test for power & control circuits including Dynamic brake is done to ensure that no damage has been done during production assembly. It is followed by continuity check on various sub-system and installation of EM2000 modules. All the connections to other electronic system are completed and power-up & self-tests done. During testing the following safety procedure are taken into consideration. The second stage of testing starts with pre-lube of engine. The engine is started and all mechanical and electrical checks including Siemen’s Commissioning checks are completed. A pre-load test is done to confirm that other systems are ready for load test, e.g., Inertial blower and also customer specific feature, if any. During the load test, the locomotive power output is dissipated in the dynamic grids to confirm the integrity of the cabling of Dynamic brake system. The locomotives not having self load Test feature, are connected to external grids. During the Load Test, measurement of cab noise and vibrations at few selected locations are also done. Finally, in the last stage, the locomotive is prepared for Track Test. Air brake system is checked to ensure its integrity, besides any other specific feature which remains to be checked. The track test is done on a test track of 1/2 miles length approx. with maximum permissible speed of 35 kmph.(located in Diesel Division). it is done for single unit as well as multiple unit. The functioning of speed indicator, ground relay and pneumatic controls checked, besides push pull test for Dynamic brake Drag operation. A pre-delivery inspection is carried out by down-loading all the fault/unusual message encountered during testing of the loading and a final inspection carried out before dispatching the locomotive. On microprocessor units whenever a module is installed or removed, power supply to the computer is switched off. A wrist grounding strap is used. All the electronic system should be disconnected prior to megger and hi-pot testing. To check the continuity and test point voltage, only digital type meter should be used Under open circuit condition, the main generator should not be excited. The meter leads and jumpers should not touch the carbody ground from 15V circuits. Test points in 15 Volt supply should not be jumpered. Engine blow-out must be performed before starting the engine if the engine has been down for eight hours or more. Some preliminary tests like checking of hand brakes, wheels, air compressor, engine oil, dust etc. are done before starting the actual testing. The testing consists of the following well defined steps sequentially 15.3 Hi Pot test Trainline continuity Lighting circuit Blower/Fans operation Power contactor operation EM2000 module application and computer preliminary test EM 2000 system integration Dynamic brake signals Sanding TM blower shutter Engine run Engine start AG checks Air compressor control, low air engine speed up & air system safety valve TCC phase module temperature control TCC power supplies, systems and operations test Excitation test Preload Load test Track test Traction inverter cut-out Multiple unit operation Pre delivery test Locomotive Painting: The locomotive after complete testing is brought to specially designed painting booth. The painting is done as per the following sequence: Preparatory booth The locomotive is washed, degreased and deburring of all external welded joints completed. The appropriate areas e.g., consoles in the cab, TG fan, valves & pipes, rubber side bearer etc. are masked. Painting Booth There are two painting booths where the following activity are done: The external is coated with the epoxy primer. The cab and long-hood exterior surfaces are given polyurethane paint coat. The polyurethane masked stickers as per the painting style ( pertaining to rail road name, road number and longitudinal strips) are affixed at the appropriate locations. The masks are removed after the final painting. The external surfaces including underframe & bogies are then given one coat of polyurethane paint. Two hours drying time is given before applying another coat of the same paint. The dry & wet gauges are used to measure the paint thickness . Normally the paint thickness is of the order of 6 thou and its uniformity over the surface is maintained by the experience of the painter. EMD also have separate painting booth for small piece parts and underframe. The underframe assembly after fabrication is given one coat of epoxy paint before & after piping and cabling. Similarly assembled equipment rack is also given one coat of epoxy paint. 16. 16.1 Visits To Various Facilities Visit To M/S Atchison Castings/Kansas -USA Atchison Castings Corporation (ACC) was re-organized in 1991 with the purpose of becoming a broad based foundry company. ACC products are iron and steel castings ranging in size from 1 to 120, 000 lb. ACC customers are leaders in their own field and include General Motors, Caterpillar, General Dynamics, Rockwell International, Westinghouse, John Deere, General Electric, Morrison Knubsen, Bombardier, ABB etc. The company was founded in Atchison, Kansas in 1872 to supply iron castings to the Railroads. In 1956, the facility was acquired by Rockwell International. In 1991, ACC acquired Rockwell’s Foundry in Atchison, Kansas and Machine Shop in St. Joseph, MO. All the castings are electronically analysed in the design development process and create modifications using solidification software techniques, which optimise quality and cost without adversely affecting functional performance. M/s Atchison Casting is using their proprietary bonding agent. They have also very excellent sand recovery system. All the casting ranges produced by ACC Castings are machined in fully finished condition at St. Joe division (Atchison Castings Machine Shop) which is a separate unit. The casting of truck requires one piece thin walled, high integrity, frame castings. With solidification and mould filling simulation on computer, the company is able to achieve excellent quality. Bogie frame for HTSC truck have been developed as U-section in place of traditional Box-section. This design eliminates use of cores. The use of cores increase the cost of production and decrease the quality of castings. M/s GM/EMD and M/s Atchison Castings have collaborated for development of this design. It is learnt that for future supplies of cast steel HTSC bogie frames to DLW, M/s Atchison Casting has entered into a TOT contract with M/s Simplex Engg. & Foundry Works/Bhilai. 16.2 Visit To M/S Lord Corporation/ Erie/ PA - USA Lord Corporation have facilities for designing, manufacturing and testing of metal bonded rubber components as per customer requirements. Main component supplied to EMD is metal bonded rubber spring used in secondary suspension and metal bonded rubber bushes for various joints. The design of metal bonded rubber spring is done on FEM package to optimise the profile of rubber to avoid stress concentration. Lord Corpn. have modern manufacturing facility for manufacture of metal bonded rubber components. Transfer moulding process is followed for moulding the rubber. For bonding between metal and rubber, they use special type of chemical developed for this purpose. M/s Lord corporation have extensive fatigue testing facilities. Company has set up new testing shop which is equipped modern fatigue testing machines, vibration shaker which are controlled by computer various data are recorded and analysed further. since major percentage of their products are supplied to aircraft industry, so they have installed three axis machines by which they can conduct all modes of testing simultaneously. The locomotive components are required to be tested for one million cycle at varying frequency. 17. Computer Aided Design By Unigraphics EMD uses Unigraphics package which is a completely integrated software and is used for drawing-drafting and modelling. The underframe, car body, cab, bogie frame and other bogie components such as wheels, axles, axle box, traction motors, suspension and brake rigging components are generated by solid modelling and assembled together. The package is very useful for preparation of layouts and study of infringement/clearances between different components of bogie. The package also enables calculation of weights, moment of inertia and centre of gravity which are required for vehicle dynamics studies. The models prepared by Unigraphics can be transferred to ANSYS for finite element analysis. The package is supported by standard library of components such as nuts, bolts, screws, etc.; the components most commonly used can be generated and can also be included in the library. Sizing of various cross section was done by keeping section modules of this bogie frame same with a similar bogie frame with box section. Afterwards optimisation of sections were carried out by FINITE ELEMENT ANALYSIS by applying load cases. 18. Recommendations 18.1 DLW should install Unigraphics system and ANSYS FEM package not only to fully assimilate EMD technology but also develop expertise in design of new locomotives of horse power ranging from 3000 to 5000 hp with EMD 12 cylinder and 20 cylinder engines. 18.2 DLW should follow EMD project management and design review process in design and manufacture of locomotives and assemblies. GT46MAC LOCOMOTIVE Specification Track Gauge Total Weight on Rails Design Speed Wheel Arrangement (top of rail to top of cooling fan) Overall Length Over Buffers Fuel Capacity Cooling Water Capacity 1676 mm 126 t 100 kmph Co-Co 4,120 mm Height 21, 245 mm 6,000 L 1144 L Performance Specification TCV Starting Tractive Effort Braking effort capability Engine 4,000 540 kN 270 kN 16-71OG3B Turbocharger Fuel Injection High Efficiency Unit Fuel Injection Traction Technology AC-AC No. of invertors One/truck EM2000 Advanced Computer 32-bit microprocessor Reduction in modules and components compared to Dash-2 series controls Improved reliability and performance Information can be downloaded to a laptop computer Flexible and expendable to accommodate future system enhancements Complete self-diagnostics Archived unit history data, HTSC Bogie No wearing surfaces extends bogie overhaul intervals to 1.6 million km Dual high adhesion and high speed Available gear ratios for heavy haul and passenger operation Cab Features Air operated windshield wipers Dual desk type control console - optional Multi-resettable vigilance controls - optional Air System Direct drive air compressor Brake System Electronic Air Brake System Reliability and Serviceability * * * 90-day maintenance intervals AC motors doubles traction motor life No running maintenance required No brushes, commutator, or rotor insulation No flashovers Bogie Inverter Control High level of reliability with fewer parts 1.6 million kilometre overhaul with HTSC Bogie 6-year engine overhaul period Safety Aspects Increased Crashworthiness Provision of Anti-climber