Large Diameter Re-Rounding Clamps

advertisement

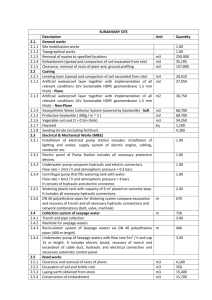

Operating instructions and Specification’s for Large Diameter Re-Rounding Clamps Products by innovation not imitation Helping you make the right connections™ Models covered by this manual: 01-08-100 Power assisted re rounding clamp + pump 400mm 01-08-103 Power assisted re rounding clamp + pump 500mm 01-08-106 Power assisted re rounding clamp + pump 630mm 01-08-109 Power assisted re rounding clamp + pump 710mm 1 INDEX. Schematic parts drawing............................ 3 Parts list and product codes ....................... 4 Pictorial representation .............................. 5 Specifications ............................................ 6 General description ................................... 7 Safety instructions ..................................... 8 Instructions for use .................................. 9 Certificate of conformity ............................ 12 Certificate of calibration ............................. 13 Warranty information ................................ 16 2 Product diagram 1 13 8 12 15 9 5 7 14 6 11 2 3 4 10 3 Product description Product code Quantity Power assisted re rounding clamp + pump 400mm Power assisted re rounding clamp + pump 500mm Power assisted re rounding clamp + pump 630mm Power assisted re rounding clamp + pump 710mm 01-08-200 01-08-300 01-08-400 01-08-500 1 1 1 1 1. NIKE cylinder c/w eye bolt (universal) 2. Support bar cam c/w spacers and screws (universal) 3. Support bar location profiles (universal) 4. Segment location pins (universal) 5. Middle segment 400mm 5. Middle segment 500mm 5. Middle segment 630mm 5. Middle segment 710mm 6. Eye bolt location segment 400mm 6. Eye bolt location segment 500mm 6. Eye bolt location segment 630mm 6. Eye bolt location segment 710mm 7. Hydraulic cylinder segment 400mm 7. Hydraulic cylinder segment 500mm 7. Hydraulic cylinder segment 630mm 7. Hydraulic cylinder segment 710mm 8. Eye bolt (universal) 9. Eye bolt location pin (universal) 10. Set of reducing shells (3 pc’s) 400 to 355mm 10. Set of reducing shells (3 pc’s) 400 to 315mm 10. Set of reducing shells (3 pc’s) 500 to 450mm 10. Set of reducing shells (3 pc’s) 500 to 400mm 10. Set of reducing shells (3 pc’s) 630 to 560mm 10. Set of reducing shells (3 pc’s) 630 to 500mm 10. Set of reducing shells (3 pc’s) 710 to 630mm 11.Spare hydraulic pump (universal) 12. Hydraulic connector (universal) 13. NIKE cylinder (universal) 14. Spare hydraulic hose complete (universal) 15. Safety security chain 01-08-209 01-08-210 01-08-211 01-08-212 01-08-213 01-08-214 01-08-215 01-08-216 01-08-217 01-08-218 01-08-219 01-08-220 01-08-221 01-08-222 01-08-223 01-08-224 01-08-225 01-08-226 01-08-101 01-08-102 01-08-104 01-08-105 01-08-107 01-08-108 01-08-110 01-08-205 01-08-207 01-08-208 01-08-206 01-08-227 1 2 4 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 3 3 3 3 3 3 3 1 1 1 1 1 4 5 Specifications. Materials: Finish: Mild Steel EN3A Chrome Plated Tube Powder coating / zinc plated (Steel) Dimensions: 400mm Re-rounding clamp (H x W x D) Liners/inserts 400mm x 315mm Liners/inserts 400mm x 355mm 500mm Re-rounding clamp (H x W x D) Liners/inserts 500mm x 450mm Liners/inserts 500mm x 400mm 630mm Re-rounding clamp (H x W x D) Liners/inserts 630mm x 560mm Liners/inserts 630mm x 500mm 710mm Re-rounding clamp (H x W x D) 530mm x 200mm x 530mm 200mm x 120mm x 340mm 200mm x 120mm x 340mm 630mm x 200mm x 630mm 200mm x 150mm x 425mm 200mm x 150mm x 425mm 825mm x 200mm x 825mm 200mm x 200mm x 540mm 200mm x 200mm x 540mm 1100mm x 200mm x 960mm Weight: 400mm Re-rounding clamp 500mm Re-rounding clamp 630mm Re-rounding clamp 710mm Re-rounding clamp Liners/inserts 400mm x 315mm Liners/inserts 400mm x 355mm Liners/inserts 500mm x 450mm Liners/inserts 500mm x 400mm Liners/inserts 630mm x 560mm Liners/inserts 630mm x 500mm Hydraulic hand pump Oil Volume: Oil Type: 60 Kg 66 Kg 75 Kg 90 Kg 7 Kg 5 Kg 7.2 Kg 9.2 Kg 11.2 Kg 13.8 Kg per per per per per per per per per per segment segment segment segment segment segment segment segment segment segment NIKE PH70-500 600cm ISO VG 10 or equivalent 6 This unit is design and manufactured to meet the requirements of National Grid Gas Industry Standards GIS/PL2-5:2006 Part 5 Electrofusion ancillary tooling. Caldervale Technology Ltd has a policy of continuous improvement in product quality and design. Caldervale Technology Ltd therefore reserves the right to change the specification of its models at any time, without prior notice. Important! This manual outlines the operation of the hydraulic large diameter pipe re-rounding clamps. This manual forms a part of the product to which it relates. It should be kept for the life of the product. Any amendments issued by Caldervale Technology Ltd should be incorporated in the text. The manual should be passed to any subsequent holder or user of this product. General description. The equipment has been designed to re-round the P.E. pipe from 315mm to 710mm (dependant on model) prior to carrying out the electrofusion jointing process on SDR11 and SDR17 pipe work in accordance with Gas Industry Standards GIS/PL2-5:2006 Part 5 Electrofusion ancillary tooling. Pipe is re-rounded by using a hydraulic unit, and can then be locked off in position, whilst the pipe is re-rounded. The units have been manufactured so that inserts can be fitted and used on various pipe dimensions. These clamps will not cure flattening in previously squeezed off pipe, where the clamp comes into contact with scraped pipe, the area must be re-scraped before fitting into the electrofusion coupler 7 First Use Before operating the clamp for the first time, the rerounder must have its hydraulic circuit ‘purged’ to eliminate any possible air in the system. Air can collect in the hydraulic system when hoses or tools are connected and this can lead to problems in operation. To bleed the system run the tool or ram through 3-4 cycles (pumping to full extension then releasing) without any load. At the same time make sure that the tool or ram is kept lower than the pump so that the air can travel back to the oil reservoir in the pump. Then bleed the pump oil reservoir. Top up the pump with oil if necessary. Before using It is important to ensure all component parts are present and in serviceable condition. Check the pump, hose and connectors for damage. Ensure the reducing inserts are fitted with the correct screws Safety Instructions 1. Read FIRST USE procedure before using the tool. 2. It is imperative that all possible precautions are made to avoid unexpected movement of the tool during use. 3. Never operate the hydraulic cylinder beyond its maximum stroke. 4. The pump is fitted with a safety valve to stop overloading. This is factory set and MUST NOT be tampered with. 8 5. The clamps are heavy between 60Kg & 90Kg dependant on model care should be taken when in use. 6. To avoid injury the re-rounder should be closed and secured and the safety chains latched in position with the hydraulic cylinder extended for transportation, lifting must be by 2 persons. 7. Operatives should wear eye protection, gloves, safety headwear & footwear when using the equipment. Instructions for use. 1. The tool consists of a steel 3 segment body with hinges and transportation eyes, a hydraulic pump and optional liner shells to increase the operating range of the tool. 2. The tool should ideally be positioned onto the pipe using a suitable powered lifting device. Chains and shackles or webbing slings should be connected through the eyebolts or lifting handles to allow ease of movement. The tool should never be opened more that the length of the safety chain, neither should the safety chain ever be removed or left disconnected. 3. When the tool is correctly positioned, the cylinder eyebolt should be positioned so that the clevis pin can be passed through the first clevis plate, the eyebolt and the second clevis plate easily. 4. The hose connector from the pump can then be fitted to the coupler on the hydraulic cylinder, to do this, ensure the coupling locknut is free to rotate and at the base of the stem nearest the cylinder. 9 5. After wiping to remove loose dirt etc. firmly insert the probe on the hose into the cavity in the cylinder coupler and fully lock in position with the locknut. 6. To close the segmented body together and initiate the re rounding effect, ensure the open/close valve on the pump is shut prior to operating the pump handle in a regular motion. 7. Pressure will build up inside the cylinder forcing the piston to move in the direction of the arrow in picture 1 and thereby close the segments together. 8. Allow sufficient time for the re-rounding effect to take place prior to releasing the cylinder pressure by opening the open/close valve on the pump. Instructions for removal after pipe re-rounding. Care must be taken on removing the clamp to ensure injury to operatives is avoided. Transport and Storage 1. Release the pressure in the circuit by opening the valve on the pump unit. 2. Release the hydraulic couplers/hose between the pump and cylinder. 3. Remove the eye bolt pin this will allow the re-rounder to relax around the pipe. 4. It should be possible to now lift the re-rounder clear of the pipe. 10 5. Care should be taken not to cause damage to the already re-rounded pipe end. Storage IMPORTANT: When hydraulic equipment is not in use: 1. 2. 3. 4. Store the tool in an upright position. Clean the equipment. Store in a clean damp free environment Make sure the store is not subject to extreme temperature changes 5. Ensure the pressure in the cylinder is released. Maintenance Hydraulic cylinder cleaned and dirt free Lubricate all moving parts at regular intervals. Use only OEM spare parts (NIKE) NOTE: AN EXCESS OF OIL WILL RENDER THE PUMP INOPERATIVE Use only hydraulic oil type HL or HM (30cSt at 40°C) Tool Grease and check screw threads at regular intervals. Inspect and replace damaged security chains. Inspect and lubricate all moving components if necessary. 11 EC DECLARATION OF CONFORMITY MACHINERY SUPPLIER: Caldervale Technology Limited SUPPLIER’S ADDRESS: Bretfield Court, Dewsbury, WF12 9DB, UK Declares that the Machinery described below: Make: CTL Product: Maxifuse™ Hydraulically Powered Re- rounding clamps Type: 400mm c/w pump. 500mm c/w pump. 630mm c/w pump. 710mm c/w pump. Reference No: 01-08-100, 01-08-103, 01-08-106 & 01-08-109 Conforms to the following Directives: 98/37/EC Machinery (Safety) Regulations (as amended) Meets the following standards: Safety of Machinery BS EN 12100: 2003, BS EN 982: 1996 Gas Industry Standard GIS/PL2-5: 2006 Part 5 Electrofusion ancillary tooling Complies with, or is designed and constructed so far as is possible to comply with the relevant essential health and safety requirements, taking into account the state of the art. Modifications to the equipment without prior approval by the undersigned will render this Declaration null & void For and on behalf of the Manufacturer: Signature: ……G L Lilley………… Gordon Lilley – Managing Director (CE Responsible Person) Signed at: ……DEWSBURY………………….. on: 5th February 2007…….(date) Signature of this Declaration of Conformity authorises the manufacturer or his authorised representative in the community to affix the CE Mark to the equipment 12 Certificate of calibration. • This product has been inspected and tested in accordance with the ISO9001 quality control systems and procedures in place at Caldervale Technology Ltd, Dewsbury. • This product has no calibration period, periodic, safety inspections should be carried out by the operator if in any doubt please contact the manufacturer for further information Decommissioning & Disposal Instructions These give the instructions for decommissioning and disposal of the equipment and confirm how it is to be taken out of service safely, in respect of the Essential Health and Safety Requirements. • If a Maxifuse™ Hydraulically Powered Re-rounding tool has reached the end of its useful working life and cannot be refurbished it must be disposed of through a licensed scrap or waste disposal facility. Alternatively, a reverse engineering company could be used to strip the equipment for recycling purposes. • Waste hydraulic oil, similarly, must be disposed of via a licensed waste disposal route. • Disposal is the responsibility of the Customer this can also be achieved by returning the product back to the manufacturer Warranty Information. 1. Extent of Warranty. (a) Subject to clauses 2 and 3, Caldervale Technology Ltd warrants to the end-user customer that its products will be free from defects in materials and workmanship, for six months after the date of purchase by the end-user customer, subject to providing proof of purchase. If Caldervale Technology Ltd receives, during the warranty period, notice of a defect in product which is covered by this warranty; Caldervale Technology Ltd shall either repair or replace the product, at its option. Any replacement product may be either new or like-new, (b) 13 (c) (d) (e) 2. provided that it has functionality at least equal to that of the product being replaced. All warranty work will be carried out by Caldervale Technology Ltd unless otherwise agreed. On-site warranty and repair or replacement services are available from authorised Caldervale Technology Ltd service facilities world-wide. Customers shall prepay shipping charges for products returned to Caldervale Technology Ltd for warranty service, and Caldervale Technology Ltd will charge for return of the products back to the customer. This warranty statement gives the customer specific legal rights. The customer may also have other rights which vary from country to country in the world. Pre-conditions for Warranty Application. Caldervale Technology Ltd’ warranty covers only those defects which arise as a result of normal use of the product, and this warranty shall only apply in the following circumstances: (a) All the instructions contained in the operating manual have been complied with; and (b) None of the following apply: (i) Improper or inadequate maintenance; (ii) Physical abuse; (iii) Unauthorised modification, misuse or any use not in accordance with the operating manual and good industry practice; (iv) Operation outside the products specifications; (v) Improper site preparation or maintenance; (vi) Faulty pipe. 3. Limitations of Warranty. (a) Caldervale Technology Ltd does not warrant the operation of any product to be uninterrupted or error free. Caldervale Technology Ltd makes no other warranty of any kind, whether express or implied, with respect to its products. Caldervale Technology Ltd specifically disclaims the implied warranties of satisfactory quality and fitness for a particular purpose. To the extent that this warranty statement is inconsistent with the law of the locality where the customer uses the product, this warranty statement shall be deemed modified by the minimum necessary to be consistent with such local law. (b) (c) 14 (d) (e) To the extent allowed by local law, the remedies provided in this warranty statement are the customer’s sole and exclusive remedies. This tool has been designed for the range of pipes available at the time of its design and development. Caldervale Technology Ltd can accept NO liability for the unit’s ability or otherwise to work with new or different pipes that subsequently appear in the market place. 15 Please complete this information and keep it safely with your proof of purchase receipt. You will require it for any warranty claim. Where purchased ............................................................... Date of purchase ............................................................... Name & address of purchaser ............................................................... ............................................................... ............................................................... ............................................................... ............................................................... ............................................................... Type of tool ............................................................... Serial number ............................................................... 16 For Service and repair please contact: Caldervale Technology Ltd Bretfield Court Dewsbury West Yorkshire WF12 9DB United Kingdom Tel: +44 (0)1924 469571 Fax: +44 (0)1924 460951 sales@caldertech.com http://www.caldertech.com © February 2007 Revision G 17