II. Materials and Methods

advertisement

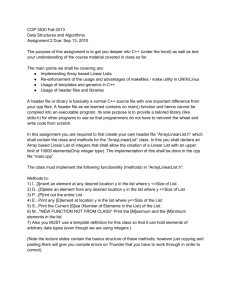

Tar Constituents Analysis of Rice Straw via Torrefaction Yun-liang Zhang, Jian Deng, Wen-guang Wu, Yun Wang, Shan-hui Zhao, Pin Zhang and Yong-hao Luo Institute of Thermal Engineering Shanghai Jiao Tong University Shanghai, P.R.China zyl_1985@sjtu.edu.cn Abstract—Torrefaction is a promising pretreatment technology for biomass, with the merits of simplicity and economical high efficiency. The pyrolysis products distribution of torrrefaction with different temperatures (200℃-300℃) was obtained in a lab scale hot-rod reactor. The tar constituents of various conditions was analyzed by GC/MS. Studies indicated that the yield of the tar was increasing when the temperature rising. There were mainly three types of tar identified, including i) phenols; ii) esters of phthalic acid; iii) acids, ketones, esters, alkanes, (not containing benzene ring). The molecular weight distribution of tar was investigated by GPC. Keywords- torrefaction; tar constituents; GC/MS; GPC I. material. We investigated the effects of different pyrolysis temperature(200 ℃ ,250 ℃ ,300 ℃ ) on the tar yield and constituents. The torrefied char were also studied. II. MATERIALS AND METHODS A. Materials Rice straw (RS) used in our studies is from Jing Shan Shanghai. The raw material was grinded into a particular size range of 100-150 μm by a KER-1/100A sealed sample preparation mill from Zhenjiang Kerui Zhiyang Shebei Co. Ltd. Then the RS particles were dried in oven for 12 h at 30 ℃ before used. INTRODUCTION The primary energy is consuming increasingly every year, therefore the renewable energy is getting more attentions. Biomass is one of the renewable resources, which is promising and in large amount. In China, about 630 million tons of crop residues are produced every year, most of which are burned and wasted in low efficiency [1]. Biomass thermo chemical conversion technologies, including gasification and combustion, have large potential to utilize biomass. However, there are some demerits of biomass, such as large volume, low energy density, high moisture content and high cost for transport. Therefore it is very necessary to pre treat the biomass to meet the demand of different utilization technologies. B. Reactors and Procedures K-type Thermocouple MFC N2 Heating electrodes K-type Thermocouple Controller & transformer First stage Temperature controller Copper gasket Tar trap MFC data Computer Torrefaction (low temperature pyrolysis), is one of the pretreatment technologies for biomass. It provides a mild pyrolysis temperature (200℃-300℃) to convert the biomass into a solid fuel of which the grindability and energy density are improved and properties are closer to the coal. many research groups [2] have investigated the effects of temperature, residence time, material types etc. on the torrefaction process and the products distribution, including the char and gaseous products. But few researchers studied the tars produced during torrefaction process. The tar problems are the key difficulties of biomass pyrolysis and gasification. How to convert and remove the tar is a very important topic. Torrefaction is a very mild pyrolysis process, of which the tars are mainly the primary tars. If the pyrolysis temperature is increased or the atmosphere is changed, the tars will further convert to secondary and tertiary tars [3]. In our study, we selected rice straw, the typical agricultural residuals as the raw Liquid nitrogen Figure 1. The schematic diagram of the first stage hot rod reactor The reactor used in our studies is the first stage of the twostage hot rod reactor by which we mainly investigated pyrolysis process of biomass, showed in Fig.1. The original concept for the two-stage hot rod reactor is from the Kandiyoti research group in Imperial College London who have done tremendous work in biomass pyrolysis and gasification [4,5]. To cooperate with Professor Kandiyoti, our research group constructed a two-stage reactor and did a lot of investigations on biomass gasification and tar conversion, also including some improvements for the reactor [6,7]. Figure 1 is the schematic diagram of the first stage hot rod reactor. The first stage is made of 316-grade stainless steel with diameters of 12 mm × 16mm and length of 300 mm. The reactor is directly heated by electrical resistance and controlled by K-type thermocouples. The system operates at atmospheric pressure. The tar trap section is a U shape stainless steel tube with diameters of 6 mm×8mm and length of 300 mm. The U shape tube is connected with the first stage by a pair of flanges and immerged into liquid nitrogen for tar trap. 4000000; column temperature: 35℃. Tetrahydrofuran (THF) was used as the eluent solvent, flow rate is 1 mL/min. The injection volume of the THF-diluted samples was 50μL. A piece of a preweighed wire mesh plug was placed inside the reactor tube and stuck at a fixed position at the bottom of the isothermal area(about 40mm high) in the first stage. A total mass of 1 ±0.01 g of rice straw was weighed and then dropped into the reactor on top of the plug. N2 is the sweeping gas with flow rate of 100 mL/min to provide a inert atmosphere and reduce the secondary reactions. The temperature in the isothermal area was set from the ambient to the set target (200 ℃,250℃,300℃) by 20℃/min, then hold for 30 min. After the pyrolysis process, the N2 was not turned off until the reactor temperature cooled down below 50℃. TABLE I. C. Tar Sampling and Water Analysis The tar trapped was washed by a mix solvent (chloromethane and methanol) with a volume ratio of CHCl3/CH3OH = 4:1. The U shape tube, the first stage reactor and the char were all washed by the solvent. The char was separated from the solution (including tar, moisture and solvent) by a weighed filter paper. Then the char was dried and weighed. The washed solution was rapidly tested for the moisture by AKF-2010 Karl Fischer. Then the solution was put into a RE3000A type rotary evaporator for 30 min to get rid of most of the solvent. After this the tar was placed in a drying oven with a temperature of 35℃ for 1 h in an inert atmosphere for the final evaporation and then weighed as mass of the tar. The dry tar was re-dissolved by the solvent and was tested by GC/MS. This may caused a small mount of loss for the tar, but it could keep consistent with the weighed tar. D. Tar GC/MS and GPC Analysis The tar constituents were tested by the Agilent 6890N GC system and QP2010NC type gas chromatograph/mass spectrometer (GC/MS) which was equipped with a splitter injector. The split ratio is 10:1, and the oven temperature is 280 ℃ . The mass spectrum was acquired using a quadrupole instrument with an electron voltage of 70 eV. The GC column was a HP-5MS column, 30 m long, 0.25 mm diameter, and with a film thickness of 0.25 μm, with a flow rate of 2.4 mL/min. The column oven temperature was programmed from 45℃(held for 5 min) to 180 at 5 ℃/min, then increased from 180 to 300℃ at 20 ℃/min, and held for 10 min; each sample volume is 1μL. The molecular weight distribution of the tar constituents were tested by a GPC(Gel Permeation Chromatography) analyzer produced by Waters Inc., USA. The instrument configuration and operating condition: Waters 1515 pump; Waters 2414 differential refractive index detector; column type: HR3, HR4, HR5(7.8×300 mm); detectable molecular weight range: HR3:500-30000, HR4:5000-500000, HR5:2000- III. RESULTS AND DISCUSSION A. Products Distribution via Torrefaction PRODUCTS DISTRIBUTION OF RICE STRAW VIA TORREFACTION T/℃ Tar /% Char/% H2O/% Gas/% 200 2.42 85.83 9.32 2.43 250 5.87 68.55 14.30 11.28 300 13.47 46.93 16.72 22.88 The Table Ⅰ shows that, with the increasing of pyrolysis temperature from 200℃ to 300℃, the char yield is decreasing from 85.83% to 46.93%. The color of the char was getting darken then be black. Deng [8] has investigated the characteristics of the torrified char and found that the grindability was greatly improved by torrefaction, most of the alkali metal and about 60% of total energy were kept in the char of 300 ℃ . The condensable product yield of tar and moisture are increasing from 2.42%, 9.32% to 13.47%, 16.72% respectively, with the rise of the temperature (200℃-300℃). The tar will analyze in next part. The moisture is increasing not only because of the vaporization of external moisture contained in RS, but also the breaking of chemical bond to release of OH, -H radicals and form moisture. The non condensable gas is greatly increasing when the temperature rising. Most of the detected gas are CO2, CO and small amount of CH4 [8]. B. The Tar GC-MS Analysis Fig.2 shows the GC/MS chromatogram of rice straw tar samples with different pyrolysis temperature (200℃,250℃,300 ℃ ). To analyze the tar in macro ways, the tar yield is increasing from 2.42% to 13.47% with the temperature rising. And the numbers of constituents of tar is obviously increasing from 200℃ to 300℃ as can be seen in Fig.2. The constituents of tar before residence time 15 min were not detected. It is probably because of the loss of some easily-volatilized small molecular weight tars due to the rotary evaporator process (mentioned above). However, the yield of the light tars lost is small which could be explained by the tar GPC analysis. To analyze the tar in micro way, Table Ⅱ shows the identified tar constituents under different pyrolysis conditions (200℃,250℃,300℃). The identified tar constituents in Table 2 was selected by principles which was that the quality value of each constituent is larger than 60 (for the MS chromatogram analyze). That made the tar identified relatively more precise and believable. The constituents detected with quality value lower than 60 and large molecular weight (> 400g/mol) were all out of considerations. There are mainly three types of tar constituents, that is i) phenols , which are the phenol derivates with forked chain including methoxy, hydroxyl, aldehydes, alkanes, olefins group. ii) esters of phthalic acid. iii) acids, ketones, esters, alkanes, which are not containing benzene ring. Except for the three main types of tar, the furans (furan derivates) and sugars (monomer) are also detected. Some of the tar constituents we Abundanc e T IC: 20110413-R S200-Z YL(2).D\ da ta.ms 38.146 38.756 55000 Ab u n d an c e Ri ce st r aw, 200¡æ£¬30mi n 50000 75 0 0 0 39.438 T IC: 2 01 1 0 4 15 -R S2 5 0 -Z Y L.D \ da ta .ms 3 8.1 4 6 Ri ce st r aw, 250¡æ£¬30mi n 70 0 0 0 45000 65 0 0 0 3 4 .8 61 40000 60 0 0 0 40 .236 38.580 35000 55 0 0 0 50 0 0 0 38.390 38.492 38.421 37.544 30000 45 0 0 0 37.996 36.872 38.065 25000 38 .3 8 9 40 0 0 0 35 0 0 0 34.046 36.077 20000 30 0 02 0.5 35 25 0 0 0 35.050 15000 2.947 10000 1 8.6 6 0 2 4 .28 5 3 7 .29 4 3 4 .0 4 9 20 0 0 0 36.402 15 .4 0 8 1 9 .30 1 15 0 0 0 2 7 .59 1 10 0 0 0 5000 50 0 0 0 0 5.00 10.00 15.00 20.00 25.00 30.00 35.00 40.00 45.00 5.0 0 1 0.0 0 1 5 .0 0 2 0 .00 2 5 .0 0 30 .0 0 3 5.0 0 4 0 .00 4 5 .0 0 T ime --> T ime--> Ab u n d an c e T IC: 2 0 1 1 04 1 8 -R S3 0 0-Z YL .D \ d a ta .ms 3 8 .1 45 Ri ce st r aw, 300¡æ£¬30mi n 22 0 0 0 0 3 8 .7 57 20 0 0 0 0 37 .5 4 1 3 9 .44 1 18 0 0 0 0 1 8.6 8 7 16 0 0 0 0 3 6.8 36 .0 76 39 4 0 .2 43 14 0 0 0 0 12 0 0 0 0 41 .2 2 0 3 4.8 6 2 3 5 .0 4 5 3 8 .5 81 373.9 93 9.2 342 8 .4 4 4 10 0 0 0 0 1 9.2 9 4 23 .0 2 4 80 0 0 0 1 8 .9 82 2 4.2 7 5 18 .7 5 22 2 .0 1 8 60 0 0 0 40 0 020.5 4 9 2 5 .71 1 85 27 .5 01 11 45 .6.4 06 33 7.3 797 .8 980 2 36 .3 3 7 .2 72 34 .0 3 29 6 34 2.71 0 3.9 5 .9 2 57 3 33 3 .5 .74 86 90 4 3 3.4 .7 66 33 4 3 .9 90 20 0 0 0 0 5 .0 0 10 .0 0 1 5.0 0 2 0 .0 0 2 5 .00 3 0 .0 0 3 5 .0 0 40 .0 0 4 5.0 0 T ime--> Figure 2. The GC/MS chromatogram of rice straw tar samples with different pyrolysis temperature (a) (b) (c) Figure 3. The GPC chromatogram of rice straw tar samples with different pyrolysis temperature (a-200℃,b-250℃,c-300℃) TABLE II. IDENTIFIED TAR CONSTITUENTS UNDER DIFFERENT PYROLYSIS CONDITIONS Reletive Concentration /% Residence Time (min) Formula MW (g/mol) Library/ID 15.6805 C15H32 212 Dodecane, 2,6,10-trimethyl- 15.6862 C15H28O4 272 Oxalic acid, isobutyl nonyl ester 17.7576 C8H10O 122 Phenol, 3-ethyl- 18.3985 C5H8O3 116 18.6617 C9H18O2 158 (S)-(+)-2',3'- Dideoxyribonolactone Propanoic acid, 2-methyl-, 3-methylbutyl ester 18.6846 C5H8O3 116 2-Oxo-n-valeric acid 18.7532 C6H6O2 110 9.19 18.9821 C6H8O4 144 1,2-Benzenediol 1,4:3,6-Dianhydro-.alpha. -d-glucopyranose 19.2968 C8H8O 120 Benzofuran, 2,3-dihydro- 5.34 RS200 RS250 RS300 0.46 1.74 2.06 2.50 2.68 9.83 16.60 5.61 6.63 6.75 22.0205 C9H10O2 150 2-Methoxy-4-vinylphenol 3.91 4.32 23.0218 C8H10O3 154 Phenol, 2,6-dimethoxy- 3.82 6.19 23.2793 C7H6O2 122 Benzaldehyde, 4-hydroxy- 24.2749 C8H8O3 152 Vanillin 25.7111 C10H10O4 194 Dimethyl phthalate 25.7168 C9H9NO2 163 27.4678 C9H14N2S 182 Benzonitrile, 3,4-dimethoxy4,4-Dimethyl-5-methylene-2allylamino-2-thiazoline 27.5822 C10H14O2 166 Phenol, 2-methoxy-4-propyl- 27.5879 C9H12O3 168 Homovanillyl alcohol 32.1712 C10H12O4 196 Benzaldehyde, 3,4,5-trimethoxy- 33.7677 C13H26O 198 33.9107 C16H22O4 278 2-Undecanone, 6,10-dimethyl1,2-Benzenedicarboxylic acid, bis(2-methylpropyl) ester 33.9679 C27H44O4 432 Phthalic acid, hexadecyl propyl ester 1.81 34.0309 C26H42O4 418 4.01 34.048 C21H28O4 344 34.048 C16H22O4 278 34.5688 C13H26O2 214 Phthalic acid, isobutyl propyl ester Phthalic acid, isobutyl non-5-yn-3-yl ester 1,2-Benzenedicarboxylic acid, butyl 2-methylpropyl ester Undecanoic acid, 10-methyl-,methyl ester 34.8606 C16H32O2 256 35.0437 C19H23NO 281 n-Hexadecanoic acid N-Benzyl-N-ethyl-pisopropylbenzamide 36.9663 C20H42 282 Eicosane 3.40 37.4412 C17H36 240 2.75 38.145 C19H26O4 318 38.391 C13H12O5S 280 Heptadecane Phthalic acid, cyclohexyl 2-pentyl ester 3,5,6-Trimethyl-p-quinone,2-(2,5dioxotetrahydrofuran-3-yl)thio- 2.08 9.64 4.73 1.93 1.46 0.72 3.13 4.21 1.94 4.02 3.04 4.09 100 1.09 14.88 4.51 7.70 25.37 5.87 detected are similar to the results concluded by Elliott [9], but their conditions with fast pyrolysis and higher temperatures were different from ours. There was only one identified tar constituent at 200 ℃ , which belonged to the ii) type. It is probably because that most of tar with 200℃ are large MW tar which could not be detected by GC/MS and the small MW tar was of poor quality value. Under 250℃ pyrolysis condition, the relative concentration of the i), ii), iii) types of tar, are 32.23%, 29.46% and 30.74% respectively. At 300 ℃ , the values are 30.06%, 10.79% and 28.81% respectively. Furans were detected both at 250℃ and 300℃. The long chain alkanes and sugars were only found at 300℃. secondary reaction with the i) and iii) type tar. There was no i) type tar detected at 200 ℃, it is consistent to the decomposition temperature range of 280-500 ℃[12]. To analyze the tar constituents in terms of lignocellulose level, the content of the cellulose, hemicellulose and ligin for rice straw are 34%,27.2% and 14.2% respectively [10]. The rest of the rice straw are inorganic minerals and organic extractives. The i) type tar are oriented from the thermal decomposition of lignin, which was concluded by T.A. Milne etc.[3].The iii) type tar (especially long chains) may be from the pyrolysis of organic extractives(including fats and waxes). The furals and sugars are from decomposition of cellulose and hemicellulose [3,11]. The ii) type tar may be from the Fig.3 shows the GPC chromatogram of rice straw tar samples with different pyrolysis temperature (200℃, 250℃, 300℃). The peaks between the residence time 20-35min are for the tar. According to the specification curve, the residence time 31.803 min refer to the molecular weight of 500 g/mol. To integral the peak area before and after the selected residence time, the molecular weight distribution of tar will be obtained. Table Ⅲ is the results after calculation. It indicated that, with the growing pyrolysis temperature, the amount of smaller MW C. The Tar GPC Analysis TABLE III. MOLECULAR WEIGHT DISTRIBUTIONIN OF THE BIOMASS TAR SAMPLES (WT%) T /℃ 200 250 300 MW<500 34.93 53.77 65.54 MW>500 65.07 46.23 34.46 tar constituents(<500g/mol) increased and the amount of lager MW tar (>500 g/mol)decreased. IV. CONCLUSION The effect of the temperature on rice straw torrefaction products distribution was investigated in a lab scale hot rod reactor. Tar constituents under different conditions were analyzed by GC/MS. The molecular weight distribution of tar was obtained by GPC analysis. There were mainly three types of tar, i) phenols; ii) esters of phthalic acid; iii) acids, ketones, esters, alkanes, which are not containing benzene ring. The i) tar type oriented from the decomposition of lignin. The yield of small molecular weight (<500g/mol) of tar was increasing when the temperature was rising. The mechanism of the low temperature pyrolysis and production of the primary tar needs to be studied in future. ACKNOWLEDGMENT The authors are grateful to the guiding of Professor Yonghao Luo. REFERENCES H. Liu, G. M. Jiang, H. Y. Zhuang and K. J. Wang, “Distribution, utilization structure and potential of biomass resources in rural China: With special references of crop residues” Renewable and Sustainable Energy Reviews. Vol.12, pp. 1402-1418, June 2008. [2] M. J. C. van der Stelt, H. Gerhauser, J. H. A. Kiel and K. J. Ptasinski, “Biomass upgrading by torrefaction for the production of biofuels: a review” Biomass and Bioenergy. vol. 35, pp. 3748-3762, 2011. [3] T. A. Milne, R. J. Evans and N. Abatzoglou, “Biomass gasifier “tars” their nature, formation, and conversion” National Renewable Energy Laboratory (NREL). Golden, p 68, 1998. [4] S. M. Nuens, N. Paterson, A. A. Herod, D. R. Dugwell and R. Kandiyoti, “Tar formation and destruction in a fixed bed reactor simulating downdraft gasification: optimization of conditions” Energy Fuels, vol. 22, pp. 1955-1964, 2008. [5] F. Dabai, N. Paterson, M. Millan, P. Fennell and R. Kandiyoti, “Tar formation and destruction in a fixed-bed reactor simulating downdraft gasification: equipment development and characterization of tarcracking products” Energy Fuels, vol. 24, pp. 4560-4570, 2010. [6] Y. Chen, Y. H. Luo, W. G. Wu and Y. Su, “Experimental investigation on tar formation and destruction in a lab-scale two-stage reactor” Energy Fuels, vol.23, pp. 4659-4667, 2009. [7] W. G. Wu, Y. H. Luo, Y. Su, Y. L. Zhang, S. H. Zhao and Y. Wang, “Nascent biomass tar evolution properties under homogeneous/heterogeneous decomposition conditions in a two-stage reactor” Energy Fuels, vol.25, pp.5394-5406, 2011. [8] J. Deng, G. J. Wang, J. H. Kuang, Y. L. Zhang and Y. H. Luo, “Pretreatment of agricultural residues for co-gasification via torrefaction” Journal for Analytical and Applied Pyrolysis, vol.86, pp.331-337, 2009. [9] D. C. Elliott, “Relation of reaction time and temperature to chemical composition of pyrolysis oils” ACS Symposium Series 376, 1988. [10] D. Mohan, C. U. Pittman, Jr. and P. H. Steele, “Pyrolysis of wood/biomass for bio-oil: a critical review” Energy Fuels, vol.20, pp. 848-889, 2006. [11] B. J. Vreugdenhil, R. W. R. Zwart, “Tar formation in pyrolysis and gasification” Energy research Centre of the Netherlands (ECN), p37, 2009. [12] E. J. Soltes, T. J. Elder, “Pyrolysis in organic chemicals from biomass” edited by I. S. Goldstein, CRC Press: Boca Raton, FL, pp. 63-95, 1981. [1]