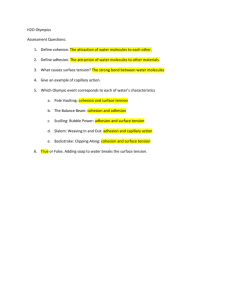

Tribology in biology

advertisement