download: "sig-cp124

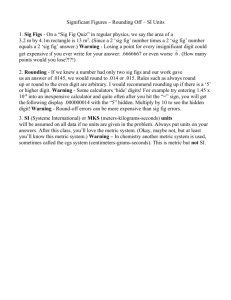

Press Release sig-cp124-e

Trade Press

Added value bottling for the dairy industry

Milk Products in Plastic Bottles

The packaging of milk products in plastic is increasing. Barrier, light protection and the right filling technology play important roles in this field of applications. Within the

SIG Beverages Division, SIG Corpoplast and SIG Asbofill combine their Know-how to offer perfect solutions for sophisticated plastic dairy packaging.

Market view

Although UHT milk packaging is dominated by carton, the fresh milk segment has been served by plastic packages for some years now. This makes plastic packaging, e.g. HDPE or PET more easily acceptable for products such as flavored milks, milk-fruit mixes, probiotic drinks etc..

Fig. 1 shows the growth rates of UHT-milk products such as UHT-milk, UHTflavored milk, UHT-cream, UHT-evaporated milk and others like soy milk etc. and

UHT - liquid dairy products (LDP). The only UHT-products packed in PET in Spain in this picture show a growth rate of more than 100% per year from their introduction in 2003 (4 mill. liters) until 2007 with a projected volume of 74 mill. liters. In the same time, the whole marketsegment grew by “only” 5,2% in the reported countries. But even HDPE saw a growth rate of 14% indicating that the plastic applications grow faster than the market average.

As shown in Fig. 2 the growth in trendy dairy drinks is booming. Mixes with juices, vitamins or other added value additives create new functional drinks, for which PET is a frequently selected packaging material to introduce these products.

PET emerges in this market segment as it offers the transparency of glass and provides high gloss, making the package attractive and allows good brand identification as well as differentiation. The packaging becomes a vehicle to convey the intended brand messages to the end user within a highly competitive environment.

Additionally, PET offers a better barrier than the alternative plastic packages that can be used.

Requirements for milk products

For milk products in general requirements on product treatment, packaging and filling technology may vary significantly. The table below shows how product treatment and filling technology influence the microbiological shelf life of milk products.

In the cold chain, with a typical shelf life of less than 10 days (or 21 days for ESLmilk or fermented milk like buttermilk, yoghurt or probiotic drinks), clean fill is the right technology to obtain the required shelf life.

The low temperature in distribution and storage as well as the limited microbiological shelf stability and the initial product treatment also imply lower demands on the protection capability of the packaging used.

Light protection

The high light barrier protection needed for UHT milk is not required for these applications, so that the products can be packed in transparent PET. If little light protection is needed, the bottles can be labeled with a sleeve or white TiO

2

based

SIG Beverages

page 1

masterbatches in various percentages can be added directly in the PET resin during injection molding of the performs, depending on the specific need.

Compared to alternative plastic packages, PET offers an additional O

2

barrier if required.

As taste changes in flavored milk are masked by the flavors/aromas added, also these products can be packaged using less light barrier protection. Increased shelf life can be obtained when increasing the requirements of the filling technology by changing from a clean fill to an aseptic filling technology.

Low acid products outside the cold chain

With UHT milk products, stored and sold at ambient conditions, the situation becomes more difficult. Extreme demands are imposed on product protection and filling technology of low acid products (Fig. 4), as in a low acid environment under ambient storage bacteria and other microorganisms can live and grow more easily.

As part of SIG Beverages, SIG Asbofill supplies aseptic filling systems of the ABF range with an integrated aseptic capper or aluminum foil sealing unit and a capacity of up to 12,000 bph using H

2

O

2 vapor technology for package sterilization.

Today low acid products such as UHT white milk, milk based drinks, milk coffees, flavored milks, yoghurt drinks, etc. are commercially filled with great success on this filling system. One big advantage of the SIG Asbofill ABF system is its extremely small aseptic chamber, making it easier and safer to control the air in this critical area. This is possible by only bringing the neck part of the bottle into the aseptic area and keeping the bottle body outside. Bottle sterilization is done by spraying a mixture of H

2

O

2

and hot sterile air into the bottle and through the oxidation effect in this process, microorganisms which could be present in the package are killed. Afterwards hot sterile air is sprayed into the bottle to eliminate residual H

2

O

2

. With variation of parameters such as temperature, H

2

O

2

dosing and cycle time, log reductions of 4,5 up to 6 can be achieved.

Excellent PET packaging – sterility guaranteed

Combined know how of aseptic filling technology (SIG Asbofill) and plastic processing technology for PET (SIG Corpoplast) guarantees a sterile high performing PET packaging.

Where the filling method provides a good microbiological quality of the milk, the packaging technology now must provide for an increased protection of vitamins and flavor.

With ESL and UHT milk, light barrier against visible light becomes the main issue.

Protection against oxygen is only required to a minimal extend, as its negative reactions are limited in the dark. Without light protection and under the influence of light in the cold storage of a supermarket, the milk looses around half its Riboflavin

(vitamin B2) within the first twelve hours. On top of that light also effects the milk protein and due to a chemical reaction the milk can get a metallic taste, the so called “light impaired taste”. This taste is already discernible after two to four hours.

Work at SIG Corpoplast shows that several gradations of light protection within

PET packaging are possible, ranging from masterbatch with high percentages of

TiO

2

up to a multilayer structure with a black light barrier layer between two white layers to retain an attractive package.

A very low transmission rate can be achieved (see fig. 6), allowing UHT milk to be adequately protected from light during its anticipated shelf life of up to four months.

Currently, the overall cost for such a solution is higher than the well established multilayer carton pack (SIG Combibloc), so that only high value milk products could benefit from this solution, allowing a more costly package as carrier for the brand.

Alternative plastics can reduce costs

Alternatively, other plastic materials which can be stretch blow molded, such as PP, can be an alternative to reduce resin cost for these packages. The multilayer page 2

solution preventing visible light from reaching the product can be applied with PP as well.

In the meantime, a number of applications using stretch bow molded PET bottles for milk drinks have been realized, as well as aseptic filling of plastic packages for this product segment.

One example is NÖM - the "Niederösterreichische Molkerei reg. Genossenschaft mbH" (which can be roughly translated as "Lower Austrian Regional Dairy

Cooperative).

In addition to classic dairy produce, the company offers a wide range of innovative wellness dairy products, such as the diet series marketed under the brand name

"Fasten" (= fasting), which were partly developed with the support of physicians and nutritionists. NÖM sells these products not only in Austria but also through the

German discount chain ALDI and various other international discounters, even in

China. For a considerable time, NÖM has been filling a large part of its products in

PET bottles blow molded on a BLOMAX 10 and two BLOMAX 12 Series III from

SIG Corpoplast. "The bottles are light, can be re-closed and are easy to drink from so they are very convenient for our customers," says Artur Hartlieb, Head of

Marketing at NÖM. He reports that the portion-sized 125 ml bottle for a quick and convenient probiotic milk drink has been a big success among consumers. With a weight of only 8.5 g, this is the smallest bottle ever to be produced on a SIG

Corpoplast machine and thus presented a formidable challenge to the Corpoplast team.

The uncontested leader in the market of ice-cold coffeedrinks is Nescafé Xpress.

The ready-to-drink energizer in its Black, White, Choco, Vanilla and Latte

Macchiato varieties, originally only offered in 250ml cans, is now also available in

250ml PET bottles.

The PET solution became possible thanks to the installation of a SIG Asbo fill linear aseptic bottle filler at the Nestlé Germany plant in Biessenhofen.

The ten-lane filler with an hourly output of 12,000 PET bottles is the ideal solution for products in the low-acid range (pH: 4.5-7) and the use of this technology permits a distribution of these products outside the cold chain.

Thanks to the special design and its neck handling of the bottle, the line can be converted to other bottle sizes and shapes or from PET to extrusion blown HDPE bottles within only a few minutes.

„We are very happy with the service provided by SIG Asbofill and the performance of the line,“ confirms André Gerber, Works Manager at Nestlé Biessenhofen.

Milchwerke Mittelelbe, in Stendal, situated between Hannover and Berlin, is also offering a large scale of modern milk mixed drinks in PET bottles. Latte macchiato,

Cappuccino and Trink Fix supershaker, amongst others – and many more to come.

These PET bottles are also filled on a ten-lane linear aseptic filler ABF 710 from

SIG Asbofill. The products produced by Elb-Milch, are UHT treated before being bottle d and attain a minimum “best before” date of 7 months outside the cold chain.

Conclusion

If it comes to value added packaging and filling solutions for milk products in plastic bottles, SIG Corpoplast and SIG Asbofill are the right people to talk to. “Bottles &

Shapes” comprises comprehensive 30 years of PET- know how and packaging answers at SIG Corpoplast from different filling goods to design and bottle production. The result is a range of standardized, modular high speed SBMmachines with highest repeatability for Light Weight bottles and other sophisticated applications. SIG Asbofill, with their broad experience in aseptic milk filling complete this offering with flexible, compact and efficient aseptic filling lines with extremely small aseptic zones.

(11.044 characters incl. blanks) page 3

SIG is a global supplier of packaging material, plant systems and services for the beverage industry and a leader in selected markets.

The SIG Beverages Division is an internationally leading manufacturer of plant systems for the production of plastic bottles (SIG Corpoplast), cans (SIG Cantec), aseptic filling (SIG Asbofill), plasma barrier coating (SIG Plasmax) and molds and tools (SIG Moldtec).

SIG Corpoplast is an internationally leading supplier of highly standardized and modular designed machines for the PET industry. The machine range comprises high speed BLOMAX Series III stretch blow molding machines from 4 to 24 blowing stations for standard, Heat Resistant and Preferential Heating technology. With more than 30 years of PET competence SIG Corpoplast offers complete service and the entire know-how chain from the characteristics of the filling goods, preform, bottle and mold design over energy saving devices to bottles with lightest possible weights.

© SIG Corpoplast GmbH & Co. KG 2006

Reprint free, two voucher copies requested

Project related contact address (can be printed, if required)

SIG Corpoplast GmbH & Co. KG,

Meiendorfer Str. 203, 22145 Hamburg, Germany

Matthias Damm,

Tel.: +49 (0) 40 67907 350

Fax.: +49 (0) 40 67907 9350 matthias.damm@sig.biz

SIG Plasmax GmbH, SIG Asbofill GmbH

Promeet Nag

Tel.: +49 (0) 40 67907 364

Fax.: +49 (0) 40 67907 9364 promeet.nag@sig.biz

Contact address (for editorial queries or courtesy copies) polymediaconsult

Dr. Michael Thielen

Hackesstr. 99

41066 Mönchengladbach

Tel.: +49 (2161) 664864

Fax: +49 (2161) 631045 mt@polymediaconsult.de

page 4