Introduction to Thermal Circuits for Steady-State, One

advertisement

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

B. Anderton

Pg. 1 of 10

Introduction to Thermal Circuits for Steady-State, One-Dimensional Heat Transfer

Abstract

Assuming steady-state, one-dimensional heat transfer via conduction and/or

convection modes, expressions are derived for thermal resistances across planar

and cylindrical interfaces. Series and parallel thermal network models are

discussed (emphasizing similarity to electrical circuit theory). Two example

applications are given, one further illustrating similarities to electrical circuit

analysis techniques, and one illustrating the competing effects of conduction and

convection in minimizing heat transferred to a refrigerant in an insulated pipe.

Various extensions to general thermal network theory are briefly surveyed.

Introduction

Thermal conduction and convection are often phenomenologically introduced in firstsemester optomechanical courses. Respective expressions governing the relation

between heat flux, in W/ m 2 , to either a linear material’s temperature gradient

(conduction) or the difference in surface and ambient temperature (convection), are

typically applied to as many as two layers and rarely considered for more composite

systems (multi-layered and involving both conduction and convection).

At the same time, a typical prerequisite for understanding optomechanical system

performance is exposure to system modeling. Often, this has been introduced in the form

of network theory for direct current electrical circuits. Such provides a well established

analytical framework for determining currents and voltages in respective loops and nodes

using the appropriate Kirchoff law. Rarely would one limit the consideration of electrical

circuits to only one or two resistor networks. Instead, complex systems are shown to be

reducible to Norton/Thevenin equivalent circuits, which capture overall system

performance in as little as one or two parameters. A key building block of this

framework is Ohm’s law, providing the basis of the electrical resistance concept.

Similarities between these two different mechanisms (heat transfer and charge transfer)

suggests that a similar network model could also apply to thermal networks. These

thermal networks would then be subject to the same principles of network theory as are

electrical circuits, with the appropriate modification of what each variable represents (e.g.

current as either charge flow or heat flow). Kirchoff’s laws for summing voltages about a

loop or currents at a point would then equally apply to thermal circuits.

The goals of this paper are as follows:

lay the foundation for thermal network theory (for special cases of conduction and

convection modes across planar and cylindrical walls),

derive appropriate expressions for thermal resistance,

describe the conditions for which series and parallel thermal models are

appropriate,

work through two typical examples of thermal network problems, and

survey extensions of thermal network theory beyond the principles/applications

covered here.

B. Anderton

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

Pg. 2 of 10

Fundamental Heat Transfer Principles

Before deriving thermal resistance expressions, some fundamental principles of heat

transfer will be briefly presented. It is assumed the reader has a qualitative understanding

of conduction and convection heat transfer modes. In-depth explanations of physical

mechanisms by which these modes occur, as well as the validity limits of transfer

expressions, are given in [1], chapter 1.

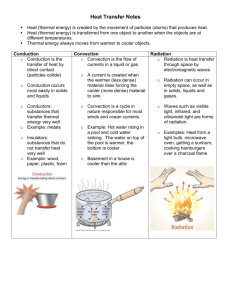

Pertinent heat transfer modes: The primary forms of heat transfer are conduction,

convection, and radiation. Within the scope of this paper, only conduction and

convection are considered.

Fourier’s law of conduction relates heat rate q (in Watts) within a linear medium of

conduction coefficient , cross-sectional area A,and temperature distribution T r , to

the temperature gradient as follows:

q A T

(1)

Newton’s law of cooling relating one-dimensional convective heat flow (along arbitrary

linear dimension x) q x from a surface to the difference between surface and ambient fluid

temperatures ( Ts and T , respectively) through a proportionality constant h, as follows:

qx h A Ts T

(2)

Note that h depends on a variety of parameters governing a specific flow condition (fluid

density, viscosity, speed, turbulence, etc.). The subscript on T indicates its reference to

fluid temperature at distances far from near-surface boundary-layer temperature

variations. Note that each of these laws may be expressed as heat flux, q q / A .

Heat diffusion equation: The heat diffusion equation governs the time and spatial

transfer of heat in a system. This “continuity equation” relates a medium’s heat

generation Egen q , net (inward) power transfer Ein Eout 2T , and net stored

energy rate of change Estored c p

T

(with density and specific heat c p ) at a point

t

according to:

2T q c p

T

t

(3)

Equation (3) can be understood in terms of an energy balance at an infinitesimal control

volume: Ein Eout Egen Estored .

B. Anderton

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

Pg. 3 of 10

Simplifying Assumptions and Coordinate Setups

This section modifies the general form of (3) for specific flow conditions and geometries,

producing spatial temperature distributions and heat rates.

Steady-state, source-free conditions: Neglecting temporal temperature changes (and thus

assuming temperature at each location in the media of interest does not vary with time),

we set T / t 0 in equation (3). We furthermore restrict attention to media without

time-dependent heat sources (or sinks) and thus set q 0 . With these two restrictions,

the heat diffusion equation reduces to:

2T 0

(4)

Now consider solutions to (4) for two specific coordinate setups.

1D heat transfer through planar wall: Assuming the Cartesian geometry of a planar wall

(Fig. 1-A) in which the primary direction of heat flow occurs parallel to the x coordinate

axis, we reduce the Laplacian of equation (4) to:

d 2T

0

dx 2

(5)

Assuming this wall has boundary conditions T x 0 Ts ,1 and T x L Ts ,2 , we

directly integrate equation (5) to produce a spatial temperature distribution according to

T x

Ts ,2 Ts ,1

L

x Ts ,1 .

(6)

This temperature distribution induces the following conductive heat flow:

qx A

dT

dx

A

L

T

s ,1

Ts ,2 .

(7)

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

B. Anderton

Medium: crosssectional area A

Temperature T

Pg. 4 of 10

Temperature T

qx

Ts ,1

r2

r1

Ts ,1

Ts ,2

Ts ,2

L

Distance r

Distance x

Medium: length L

(into the page)

Figure 1: System geometries: (A) planar wall (left), (B) cylindrical wall

1D heat transfer through cylindrical wall: Assuming the cylindrical geometry of Fig. 1B (where only radial heat transfer occurs across the medium), equation (4)’s Laplacian

takes the form

d dT

r

0.

r dr dr

(8)

Directly integrating this expression subject to boundary conditions T r r1 Ts ,1 and

T r r2 Ts ,2 yields the following spatial temperature profile:

T r

Ts ,1 Ts ,2

r

ln Ts ,2

ln r1 / r2 r2

(9)

This temperature variation gives rise to conductive heat flow via Fourier’s law:

qr A

2 L Ts ,1 Ts ,2

dT

.

dr

ln r2 / r1

(10)

Note that the radial-location-dependent cross-sectional area in this previous expression is

given by A 2 rL .

B. Anderton

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

Pg. 5 of 10

Expressions for Resistances

Recall from circuit theory that resistance Relec across an element is defined as the ratio of

electric potential difference V across that element, to electric current I traveling

through that element, according to Ohm’s law,

Relec

V

.

I

(11)

Within the context of heat transfer, the respective analogues of electric potential and

current are temperature difference T and heat rate q, respectively. Thus we can

establish “thermal circuits” if we similarly establish thermal resistances R according to

R

T

.

q

(12)

We now consider specific expressions for R based on results for the two geometries

specified in the previous section.

Planar wall conductive resistance: Again referring to Fig. 1-A and the result in equation

(7), we see that thermal resistance may be obtained according to

Rx,cond

Ts ,1 Ts ,2

qx

L

.

A

(13)

Cylindrical wall conductive resistance: Referring to Fig. 1-B and equation (10), we

obtain conductive resistance through a cylindrical wall according to

Rr ,cond

Ts ,1 Ts ,2

qr

ln r2 / r1

2 L

.

(14)

Convective resistance: The form of Newton’s law of cooling, in equation (2), lends itself

to a direct form of convective resistance, valid for either geometry.

Rconv

Ts T

1

q

hA

(15)

Series and Parallel Thermal Networks

With expressions for calculating thermal resistances in hand, we move on to the

important task of choosing appropriate models for thermal networks. The utility of

thermal resistances exists in the ease with which otherwise complicated thermal systems

are modeled. This section considers series and parallel thermal networks, drawing

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

B. Anderton

Pg. 6 of 10

analogies to circuit theory’s rules for

equivalent resistance. For simplicity, only

Cartesian geometries are considered.

Series networks: Recall from circuit theory

that resistors in series produce an equivalent

resistance between input-output terminals

that is the sum of individual resistances,

owing to the fact that each individual resistor

has the same current flowing through it.

Rseries,eq i Ri

(16)

Likewise, systems in which multiple

elements are intercepted by a single heat

flowline are modeled serially.

Fig. 2

illustrates an example series model and

Figure 2: Layered planar wall (from [1])

circuit schematic for a double-exposed,

layered window (note the presence of both

conduction and convection transfer modes). In this example, the equivalent thermal

resistance would be the sum of each resistance shown, and would relate overall

temperature difference across the network according to

Req

T1, T4,

qx

1 1 LA LB LC 1

.

A h1 A B C h2

(17)

Parallel networks: Recall that electrical resistors

in parallel produce equivalent resistance

R| |,eq 1 i Ri1 .

(18)

Such a model exists when multiple current paths

exist between two nodes. A similar situation

occurs in thermal networks when two paths

(through different media) exist between two points

of the same temperature. An example system is

shown in Fig. 3, with two equivalent schematics.

The equivalent resistance between the left and

right faces of material F (or G) is thus

1

Req

1

LG

LF

G A / 2

F A / 2

1

(19)

Note that this equivalent resistance will be less

than either individual component.

Figure 3: Parallel conduction network (from [1])

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

B. Anderton

Pg. 7 of 10

Note that this circuit model is valid only when heat flow is assumed approximately onedimensional (if significant heat flow occurred vertically between materials F and G, the

resistors-in-parallel model would be invalidated).

Example Problems

This section applies thermal resistance principles in the analysis of two example

problems, one for each geometry of interest. The first example will extend our modeling

capabilities by adding a current source to a flux-based network with specified surface

contact resistance to model an epoxy bond. The second example demonstrates

performance tradeoffs involved with scaling geometrical form factors in search of

optimum performance. These examples introduce other concepts not mentioned

previously and demonstrate the analogous relationship between thermal and electrical

circuit analysis.

Example 1: Comparing performance to specification (max temperature):

Problem statement:

o A thin silicon chip and an 8-mm-thick aluminum substrate are separated

by a 0.02-mm-thick epoxy joint (whose thermal resistance can be

2

approximated as a contact resistance of Rt ,c R t ,c / A 0.9 104 mWK )

o The chip and substrate have their exposed surfaces cooled by 25 C air,

providing a convection coefficient of 100 mW2 K .

o If the chip dissipates 104

W

m2

under normal conditions, will it operate

below a maximum allowable temperature of 85 C ?

System diagram/schematic: See Fig.

4 at the right. Note that currents are

shown in terms of fluxes (in mW2 ),

denoted

with

double-primes

( q q / A ) since areas are not

specified. This requires resistances

to be stated in terms of Ri Ri A .

Note

particularly

how

the

4

2

chip dissipation is

10 W/ m

modeled as a flux source.

Analysis:

o We seek to find whether the

Figure 4: Problem 1 diagram/schematic (from [1])

calculated value of Tc

remains below the 85 C specification.

o We start by noting, just as in electrical circuits, that the total current

entering the Tc node must equal the current leaving it:

B. Anderton

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

qc q1 q2

Pg. 8 of 10

Tc T

Tc T

1/ h

Rt ,c L / Al 1/ h

(20)

1

1

o Solving for Tc yields Tc T qc h

.

Rt ,c L / Al 1/ h

o Substituting all known values (with

Al 239 mWK )

Tc 25 C 104

W

m 2 K

100 0.9

1

4

0.33 100 10

gives

1

m 2 K

W

25 C 50.3 C 75.3 C

o Therefore, the chip will operate below the maximum allowable

temperature.

The next example considers the following two competing effects in a cylindrical

insulation system as the outer insulation radius r increases:

ln r / ri

The increase in conduction resistance Rr,cond Rr ,cond L

2

1

Rconv L

The decrease in convection resistance Rconv

(due to a larger

2 r h

exposed outer area).

Example 2: Scaling effects on system geometry

Problem statement:

o A thin-walled copper tube of radius ri is used to

transport a low-temperature refrigerant and is at a

temperature Ti that is less than that of the ambient air

at T around the tube. Is there an optimum thickness

associated with application of insulation to the tube?

System diagram/schematic: See Fig. 5 at right. Note that

per-unit-length currents q q / L and resistances R R L

are used and that the system is modeled as a serial, radial

system.

Analysis:

o Note that the optimum value of r will minimize Figure 5: Problem 2 diagram/schematic

(from [1])

current q delivered from the environment to the

, the optimum r will

refrigerant (or equivalently, since q T Ti / Rtot

between the environment and refrigerant).

maximize resistance Rtot

o Note that total resistance is calculated as Rtot

thus a function of outer radius r.

ln r / ri

2

1

and is

2 r h

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

B. Anderton

o We

find

extrema

of

Pg. 9 of 10

r

Rtot

by

calculating

d

1 1

1

r

Rtot

2 0 . This extremum occurs at r / h .

dr

2 r r h

depending

o This r / h extremum produces {minimum, maximum} Rtot

/ dr 2

on whether d 2 Rtot

o We find

r / h

is {positive, negative}.

d 2 Rtot

1

1

and

3

2

2

dr

2 r r h

d 2 Rtot

2

dr

r / h

h2

2 3

which is

always positive, and hence the extremum r / h effectively minimizes

(thus maximizing the current q to our refrigerant, the opposite of the

Rtot

desired effect).

r , we conclude that an

o Since r / h was the only extremum of Rtot

optimum thickness does not exist.

An example plot of Rtot , with contributions

from conductive and convective components,

is shown in Fig. 6, evaluated for values

, and

ri 5mm , h 5 mW

0.055 mWK

2

K

(producing

a

critical

radius

that

rcr / k 0.011m such

Note that, beyond the

rcr ri 0.006 m ).

critical radius, the performance increases with

increasing insulation radius.

Extensions not covered here

Figure 6: Effect of total resistance for

increased insulation thickness (from [1])

This discussion has limited scope to concepts/applications most likely to be of immediate

interest to the audience. A more generalized treatment of thermal network theory is

found in [1], chapter 3. Some extensions of this theory beyond the concepts covered in

this paper include:

1 1

1

.

4 rinner router

Incorporation of heat generation ( q ) effects in a circuit.

Radiative heat transfer, occurring according to the Stefan-Boltzmann law

4

Ts4 Tsurr

qrad

, can be expressed as qrad hr A Ts Tsurr where radiation

Thermal resistance of a spherical shell: Rcond

2

heat transfer coefficient hr Ts Tsurr Ts 2 Tsurr

has strong temperature

dependence. For such cases, thermal resistance may be defined similarly to the

Opti 521 Fall ‘08, Tutorial Project

Last Saved on 2/15/2016 3:09:00 PM

B. Anderton

Pg. 10 of 10

1

. This usually exists in parallel with the convective

hr A

resistance at a surface (when radiative effects are not negligible).

Heat transfer from extended surfaces (cooling fins, etc. where the 1D flow

assumption is invalid) often have tabulated expressions for temperature

T x T

distribution

and heat transfer rate qfin based on geometry and fin

b Tbase T

boundary conditions. Such a table (for fins of uniform cross section) is given in

Table 3.4 of [1]. A figure-of-merit often used for fin geometry performance

convective mode: Rrad

comparison is the fin thermal resistance, Rfin

b

qfin

(a higher Rfin value indicates

poorer cooling performance).

Under certain conditions, cylindrical and/or spherical geometries with large radii

can be approximated as planar (flat) walls.

Summary

The concepts of conductive and convective thermal resistance were derived from

fundamental laws governing heat transfer and the heat diffusion equation. Two specific

geometries (planar and cylindrical walls) were considered in obtaining explicit forms for

conductive resistances. Thermal network modeling was then covered, emphasizing the

conditions appropriate for serial and parallel networks. Two examples were then used to

reinforce the developed concepts, one drawing further similarity between the analyses of

thermal and electrical networks, and one considering the tradeoffs in conductive and

convective heat losses as geometry changed. Extensions were briefly surveyed.

In conclusion, we have successfully outlined the process of setting up and analyzing

steady-state, 1D heat transfer problems for the geometries and modes indicated. The

analytical capabilities provided in this discussion are deemed worthy tools for the system

engineer, as system sensitivities (such as change in interface temperature for incremental

changes in thicknesses, etc.) and overall system performance (whether a tradeoff in

thermal performance balances the risk of other factors, such as mechanical stiffness) can

now be achieved by recycling the analytical framework used in linear circuit theory.

Reference

[1]

F. P. Incropera, D. P. DeWitt, T. L. Bergmann, A. S. Lavine, Fundamentals of

Heat and Mass Transfer, 6th Ed., John Wiley & Sons Inc., 2006.