Supporting information

advertisement

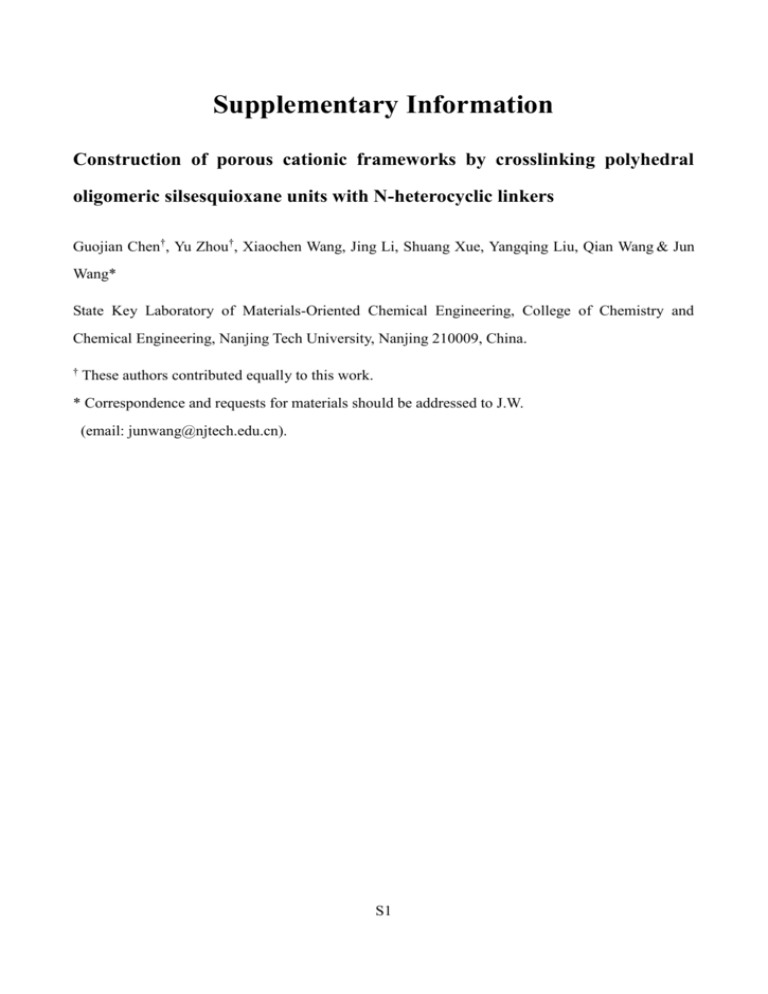

Supplementary Information Construction of porous cationic frameworks by crosslinking polyhedral oligomeric silsesquioxane units with N-heterocyclic linkers Guojian Chen†, Yu Zhou†, Xiaochen Wang, Jing Li, Shuang Xue, Yangqing Liu, Qian Wang & Jun Wang* State Key Laboratory of Materials-Oriented Chemical Engineering, College of Chemistry and Chemical Engineering, Nanjing Tech University, Nanjing 210009, China. † These authors contributed equally to this work. * Correspondence and requests for materials should be addressed to J.W. (email: junwang@njtech.edu.cn). S1 Supplementary Experimental Section Synthesis of octakis(3-chloropropyl)silsesquioxane ClPrPOSS. ClPrPOSS was synthesized by previously reported method with a slight modification. As shown in Supplementary Fig. S1, a solution of 400 mL of dry methanol and 15 mL of concentrated hydrochloric acid was placed in a round-bottomed flask, and then (3-chloropropyl)trimethoxysilane (20 mL) was slowly added into the solution. The reaction mixture within the closely sealed flask, was maintained at temperature of 40oC for two weeks until a mass of white crystalline precipitate appeared. The solution was filtered and the crystals were collected, washed several times with methanol, and dried under vacuum. The final product was obtained in 32% yield (4.5 g). Spectroscopic data of ClPrPOSS are as follows (see Supplementary Figs. S6 and 7). 1H NMR (500 MHz, CDCl3) δ 0.79 (t, 16H, SiCH2), 1.86 (qui, 16H, CH2), 3.54 ppm (t, 16H, CH2Cl). 13C NMR (125 MHz, CDCl3) δ 8.84 (SiCH2), 25.75 (CH2), 46.50 ppm (CH2Cl). Supplementary Figures and Tables Supplementary Figure S1. Synthesis of octakis(3-chloropropyl)silsesquioxane ClPrPOSS. S2 1 Supplementary Figure S2. 1H NMR of ClMePOSS. 1 Supplementary Figure S3. 13C NMR of ClMePOSS. S3 3 T -78.3 a 29 Si NMR 2 T -69.0 0 -50 -100 Chemical shift (ppm) -150 T3γ b Tn peaks T2α T2β T3α T3β T3γ T2α T3α T2β Supplementary Figure S4. (a) ppm -68.7 -70.5 -76.2 -77.9 -78.3 29 T3β Si MAS NMR spectra of ClMePOSS and (b) its fitting with multiple peaks. A small signal at –69.0 ppm and the main signal at –78.3 ppm for the as-synthesized ClMePOSS are assigned to its T2, T3 structures with a relatively high T3 / (T2+T3) ratio 0.901, indicating that the new POSS monomer possesses a high percentage (ca. 90%) of T3 structure silicons. Fitting the spectrum with multiple peaks reveals three possible T3α, T3β, T3γ silicon peaks at S4 -76.2, -77.9, -78.3 ppm, respectively, attributable to the T3 silicons originated from the minor incompletely condensed POSS units (T2α, T2β silicons) and major completely condensed cubic POSS units (Macromolecules 38, 5088-5097 (2005)). The splitting of the T3 signal can be assigned to existence of minor T2 silicons in ClMePOSS that disturb the local environments of T3 silicons. Supplementary Figure S5. MALDI-TOF MS spectra of ClMePOSS (DHB matrix, THF as the solvent). The MALDI-TOF MS result gave one sharp strong peak at m/z=813.48, index of T3 cubic POSS unit (Mw=812.48 g mol-1). Two very small peaks were observed at m/z=735.70 and 826.64 attributable to incompletely condensed POSS units of trisilanol R7Si7O9(OH)3 POSS-triol and R8Si8O11(OH)2 POSS-diol respectively (J. Organomet. Chem. 693, 1301-1308 (2008)). The above results indicated that the major POSS units were cubic structure, well in accord with the analysis result of 29Si MAS NMR spectrum of ClMePOSS. S5 3 1 2 Supplementary Figure S6. 1H NMR of ClPrPOSS. 3 Supplementary Figure S7. 13C NMR of ClPrPOSS. S6 2 1 Supplementary Figure S8. Schematic formation process of Si–C–N bonds, Tn and Qn silicons units due to the partial cleavage of Si–C bonds during the synthesis of POSS-based porous cationic framework PCIF-1. Supplementary Fig. S8 schematically depicts the formation process of Si–C–N bonds, Tn and Qn silicons units due to the partial cleavage of Si–C bonds during the synthesis of POSS-based porous cationic framework PCIF-1. The Q4-structured POSS units were resulted from the self-condensation of silanols from the formed Q3 units under the weak basic environment. Minor Q2 structure of silicons may be derived from the cleavage of Si–C in original T2 units or the decomposition of siloxane bond in Q3 units (not shown in Supplementary Figure 8). Finally, the attack of nucleophilic rigid organic linker and the distortion of POSS cages accelerate the formation of Si–C–N bonds and partial cleavage Si–C bonds to obtain Tn and Qn silicons units combined POSS-based porous cationic framework PCIF-1. Supplementary Figure S9. Various N-heterocyclic compounds used for synthesizing water-soluble POSS-ILs. S7 0.2 5.40 nm PCIF-1(M8) 5.40 nm PCIF-1(M6) 0.1 0.0 0.1 3 -1 dVp/ddp(cm g ) 0.2 0.0 0.8 3.71 nm PCIF-1(M4) 0.4 0.0 2.40 nm 3.71 nm 0.02 PCIF-1(M2) 0.00 1 10 Pore diameter dp (nm) 100 Supplementary Figure S10. BJH pore size distributions of PCIF-1 series of PCIF-1(M2), PCIF-1(M4), PCIF-1(M6), and PCIF-1(M8). S8 3 -1 Volume Adsorption (cm g ) a 200 150 100 50 0 0.0 0.2 0.4 0.6 0.8 1.0 Relative pressure (P/P0) b 0.005 3.71 nm 0.003 3 -1 dVp/ddp(cm g ) 0.004 0.002 0.001 0.000 1 10 Pore diameter dp (nm) 100 Supplementary Figure S11. (a) N2 adsorption-desorption isotherms and (b) BJH pore size distributions of the PCIF-1 network, which was prepared in the toluene solution. S9 a 400 b 0.06 72 h 0.03 72 h 2.18 nm 4.35 nm 48 h 2.18 nm 4.66 nm 36 h 2.02 nm 24 h 48 h 3 300 3 -1 Volume adsorption (cm g ) 0 -1 -1 Differential Pore Volume dVp (cm nm g ) 200 2.20 nm 5.17 nm 0 36 h 200 0 24 h 200 0 12 h 200 0 0.0 0.8 0.6 0.4 0.2 Relative pressure (P/P0) 1.0 0.00 0.08 0.00 0.08 0.00 0.1 4.00 nm 0.0 1.88 nm 2.35 nm 4.00 nm 0.1 0.0 1 10 Pore diameter dp (nm) 12 h 100 Supplementary Figure S12. (a) N2 adsorption-desorption isotherms and (b) NLDFT pore size distributions of PCIF-1(M4) using different reaction time. S10 b 0.08 o 120 C -1 400 Differential Pore Volume dVp (cm nm g ) a 0.04 120 C 2.33 nm 6.32 nm 110 C o -1 200 2.20 nm 4.68 nm o 3 110 C 3 -1 Volume adsorption (cm g ) 0 600 300 0 400 o 100 C 200 0 400 o 90 C 200 0 200 o 80 C 100 0 0.0 0.00 0.08 0.04 0.00 0.10 2.04 nm 0.05 o o 100 C 4.12 nm 0.00 0.10 2.04 nm o 90 C 3.90 nm 0.05 0.00 0.04 1.85 nm o 80 C 0.02 0.2 0.4 0.6 0.8 Relative pressure (P/P0) 1.0 0.00 1 10 Pore diameter dp (nm) 100 Supplementary Figure S13. (a) N2 adsorption-desorption isotherms and (b) NLDFT pore size distributions of PCIF-1(M4) series at different reaction temperature. S11 b 20 mL 400 15 mL 3 3 -1 Volume adsorption (cm g ) -1 -1 200 0 400 200 0.00 0.06 2.20 nm 400 2.18 nm 0 400 0.00 5 mL 2.05 nm 0.08 200 0.4 0.6 0.8 1.0 Relative pressure (P/P0) 5 mL 2.50 nm 4.35 nm 0.04 0.2 10 mL 5.86 nm 0.04 200 15 mL 4.35 nm 0.00 10 mL 20 mL 4.18 nm 0.04 0.03 0 0 0.0 2.20 nm 0.08 Differential Pore Volume dVp (cm nm g ) a 0.00 1 10 Pore diameter dp (nm) 100 Supplementary Figure S14. (a) N2 adsorption-desorption isotherms and (b) NLDFT pore size distributions of PCIF-1(M4) using different amount of solvent THF. S12 d 3.5 1.0 SBET Vtotal 2 -1 3 -1 SBET (m g ) 0.8 Vtotal (cm g ) 900 800 0.6 700 600 Average pore size Dav (nm) a 1000 48 2.5 2.0 0.4 24 3.0 12 72 24 36 Reaction time (h) 1.0 1000 Vtotal 800 0.6 600 3 -1 Vtotal (cm g ) 2 -1 SBET (m g ) 0.8 0.4 400 90 100 110 3.5 3.0 2.5 80 120 1.0 3 2 0.6 800 0.4 15 20 0.2 Average pore size Dav (nm) -1 Vtotal (cm g ) -1 SBET (m g ) 0.8 900 10 110 120 f 3.5 SBET 5 100 Temperature ( C) Vtotal 700 90 o o Temperature ( C) c 1000 72 2.0 0.2 80 60 e SBET Average pore size Dav (nm) b 48 Reaction time (h) 3.0 2.5 2.0 5 10 15 20 Amount of solvent THF (mL) Amount of solvent THF (mL) Supplementary Figure S15. Influences of reaction parameters (reaction time, temperature and amount of solvent THF) on the surface area (SBET), pore volume (Vtotal) and average pore size (Dav) of PCIF-1(M4) samples. It was apparently that the surface area, pore volume and average pore size first increased with the reaction time, reaching the maximum value at 48 h, and then decreased with longer reaction time. Similar variations were observed by surveying the influence of reaction temperature and the solvent amount. The results indicate that the surface area, pore volume and average pore size of PCIF materials can be regularly adjusted by those factors, while keeping similar type IV N2 sorption S13 isotherms and pore size distributions with sharp peaks centered at ca. 2 nm (Supplementary Figs. 3 -1 Volume adsorption (cm g ) 0 20 PCIF-3 0 20 PCIF-4 0 PCIF-5 200 0 PCIF-6 200 0 b 0.04 -1 100 0.02 -1 PCIF-2 0.00 3 a 200 Differential Pore Volume dVp (cm nm g ) S12-S14). 0.002 0.2 0.4 0.6 0.8 1.0 Relative pressure (P/P0) PCIF-2 3.25 nm 2.35 nm 5.06 nm 0.000 0.002 2.52 nm 5.78 nm 0.001 PCIF-3 PCIF-4 0.000 0.04 2.01 nm 3.93 nm PCIF-5 0.00 0.04 2.16 nm PCIF-6 2.01 nm PCIF-7 0.02 0.00 0.01 PCIF-7 50 0 0.0 1.90 nm 0.00 1 10 Pore diameter dp (nm) Supplementary Figure S16. (a) N2 adsorption-desorption isotherms and (b) NLDFT pore size distributions of PCIF-n series samples with n corresponding to various organic linkers (2: bpe, 3: bpea, 4: bppa, 5: bim, 6: tmeda, 7: dabco). S14 The stability of PCIF-1(M4) in various solvents. PCIF-1(M4) was selected as a typical sample to investigate its stability in various solvents. The sample was soaked in water, typical organic solvents (CH3OH, CHCl3, DMF, and DMSO) for 24 h at the room temperature, and then the samples were recovered by the filtration, washing and drying. All the dry samples were fully characterized by N2 sorption, SEM, XRD and FT-IR. N2 sorption experiment and textural parameters of the recovered PCIF-1(M4) samples (Supplementary Fig. S17, Supplementary Table S4) demonstrate that the porous structures of PCIF-1(M4) are well retained in spite of the slight changes of BET surface areas, total pore volumes and pore sizes. The above results are further confirmed by the no noticeable change of morphologies and crystalline states (Supplementary Figs. S18 and S19). Besides, no noticeable spectral change were observed in FT-IR spectra (Supplementary Fig. S20), indicating their excellent structural stability in water and organic solvents. In brief, the PCIF materials possess well stability in water and common organic solvents. b 0.08 0 400 -1 *CH3OH 3 200 0 400 200 *CHCl3 0 400 200 *DMF 0 400 200 0 0.0 *DMSO 0.2 0.4 0.6 0.8 Relative pressure (P/P0) 1.0 -1 -1 PCIF-1(M4)*H2O 0.04 0.00 3 200 Volume Adsorption (cm g ) 2.35 nm PCIF-1(M4) 4.28 nm *H2O 8.80 nm 400 Differential Pore Volume dVp (cm nm g ) a 0.04 2.35 nm 4.30 nm 8.68 nm 0.00 *CH3OH 2.34 nm 4.28 nm 9.50 nm 0.04 0.00 *CHCl3 2.05 nm 0.04 *DMF 4.30 nm 8.03 nm 0.00 0.10 2.05 nm 0.05 *DMSO 5.46 nm 0.00 1 10 Pore diameter dp (nm) 100 Supplementary Figure S17. (a) N2 adsorption-desorption isotherms and (b) NLDFT pore size distributions of PCIF-1(M4) after soaked in H2O or various organic solvents (CH3OH, CHCl3, DMF, and DMSO). The asterisk (*) before solvents represents the sample of PCIF-1(M4) treated in this solvent. S15 Supplementary Figure S18. (a) SEM images of PCIF-1(M4) after treated in (a, b) H2O, (c, d) CH3OH, (e, f) CHCl3, (g, h) DMF, and (i, j) DMSO. S16 o o 23.40 ,0.38 nm o 23.36 , 0.38 nm o 23.28 , 0.38 nm 5.75 , 1.54 nm PCIF-1(M4) *DMSO o Intensity (a.u.) 5.64 , 1.56 nm *DMF o 5.81 , 1.52 nm *CHCl3 o 23.38 , 0.38 nm o 5.79 , 1.53 nm *CH3OH o 23.45 ,0.38 nm o 5.81 ,1.52 nm 10 *H2O 20 30 2 Theta (degrees) 40 50 Supplementary Figure S19. XRD patterns of PCIF-1(M4) after treated in H2O or various organic solvents (CH3OH, CHCl3, DMF, and DMSO). The asterisk (*) before solvents represents the sample of PCIF-1(M4) soaked in this solvent. PCIF-1(M4) Transmittance (%) * H2O * CH3OH * CHCl3 * DMF * DMSO 2943 2854 814 1633 1399 949 1204 1079 4000 3500 3000 2500 2000 1500 1000 -1 Wavenumbers (cm ) 500 Supplementary Figure S20. FT-IR spectra of PCIF-1(M4) and the ones after treated in H2O or various organic solvents (CH3OH, CHCl3, DMF, and DMSO). The asterisk (*) before solvents represents the sample of PCIF-1(M4) soaked in this solvent. S17 1.0 -1 CO2 adsorpation (mmol g ) a 0.8 b 0.6 c 0.4 d 0.2 0.0 0.0 0.2 0.4 0.6 Pressure (bar) 0.8 1.0 Supplementary Figure S21. CO2 adsorption isotherms of PCIF-1 series (a) PCIF-1(M4) at 273 K, 1.0 bar; (b) PCIF-1(M4), (c) PCIF-1(M6), and (d) PCIF-1(M8) at 298 K, 1.0 bar. Supplementary Figure S22. Schematic image for anion exchange process of very bulky PMoV anions to replace the small Cl ions. Referring to the book of “Ion Exchange Materials: Properties and Applications” by Andrei A. Zagorodni. S18 100 PCIF-1(M8) PMoV@PCIF-1 Loss of weight (wt %) 90 80 11.0 wt% 70 60 50 100 200 300 400 500 600 700 o Temperature ( C) Supplementary Figure S23. TGA curves of PCIF-1(M8) and PMoV@PCIF-1 under air atmosphere. Cl: 1.81 wt% Supplementary Figure S24. Energy-dispersive X-ray spectrometry (EDS) spectrum and element distributions of PMoV@PCIF-1. S19 a b C1s c O1s Mo3p1/2 Mo3p3/2 P2p Si2p Cl2p 400 200 Binding Energy (eV) 0 295 290 e Cl2p 102.9 Mo3d f 100 95 210 205 h Mo3d5/2 200 195 Binding Energy (eV) Mo3p N1s 235 Intensity (a.u.) Intensity (a.u.) Mo3d3/2 235.4 230 Binding Energy (eV) 225 420 190 133.4 405 400 Binding Energy (eV) 132.8 135 130 125 395 V2p V2p3/2 517.0 N1s 401.5 410 525 P2p 140 i Mo3p1/2 415.6 415 530 Binding Energy (eV) Mo3p3/2 398.2 232.3 240 535 Intensity (a.u.) C-Cl 201.5 Intensity (a.u) 105 540 Binding Energy (eV) - Binding Energy (eV) g 280 atomic concentration Cl 200.0 1.18 at% Intensity (a.u.) 110 285 Binding Energy (eV) Intensity (a.u.) d Si2p V-O 530.1 Intensity (a.u.) C1s V2p 600 Intensity (a.u.) Intensity (a.u.) Mo3d N1s 800 •Si-O 534.2 285.7 285.4 O1s 390 516.3 V2p1/2 524.3 523.4 525 515.3 520 515 510 Binding Energy (eV) Supplementary Figure S25. High resolution XPS spectra of PMoV@PCIF-1. (a) Survey, (b) C1s, (c) O1s, (d) Si2p, (e) Cl2p, (f) P2p, (g) Mo3d, (h) Mo3p and N1s, and (i) V2p. S20 a 450 3 -1 Volume adsorption (cm g ) PCIF-1(M8) PMoV@PCIF-1 300 150 0 0.0 0.2 0.4 0.6 0.8 1.0 Relative pressure (P/P0) b 0.20 PCIF-1(M8) PMoV@PCIF-1 5.4 nm 3.7 nm 3 -1 dVp/ddp (cm g ) 0.15 0.10 0.05 0.00 1 10 Pore diameter dp (nm) 100 Supplementary Figure S26. (a) N2 adsorption-desorption isotherms and (b) BJH pore size distributions of PCIF-1(M8) and PMoV@PCIF-1. S21 Supplementary Table S1. Textural properties of PCIF-1(M4) influenced by different reaction time.a Time (h) SBET [m2 g-1]b Vp [cm3 g-1]c Dav [nm]d 12 772 0.48 2.42 24 811 0.55 2.63 36 839 0.57 2.80 48 892 0.72 3.25 72 633 0.47 2.95 [a] Reaction conditions: ClMePOSS (0.5 g, 0.62 mmol), 4,4'-bpy (0.39 g, 2.48 mmol), THF (10 mL), 100 oC, 12~72 h. [b] BET surface area calculated over the range P/P0=0.05~0.20. [c] Total pore volume calculated at P/P0=0.99. [d] Average pore size calculated by the BET method. S22 Supplementary Table S2. Textural properties of PCIF-1(M4) influenced by different reaction temperature.a Temperature (oC) SBET [m2 g-1]b Vp [cm3 g-1]c Dav [nm]d 80 500 0.26 2.07 90 863 0.55 2.53 100 942 0.76 3.23 110 1025 0.90 3.52 120 865 0.70 3.22 [a] Reaction conditions: ClMePOSS (0.5 g, 0.62 mmol), 4,4'-bpy (0.39 g, 2.48 mmol), THF (10 mL), 80~120 oC, 48 h. [b] BET surface area calculated over the range P/P 0=0.05~0.20. [c] Total pore volume calculated at P/P0=0.99. [d] Average pore size calculated by the BET method. S23 Supplementary Table S3. Textural properties of PCIF-1(M4) with different amount of solvent THF.a THF volume (mL) SBET [m2 g-1]b Vp [cm3 g-1]c Dav [nm]d 5 763 0.62 3.27 10 892 0.72 3.25 15 886 0.65 2.93 20 843 0.63 3.00 [a] Reaction conditions: ClMePOSS (0.5 g, 0.62 mmol), 4,4'-bpy (0.39 g, 2.48 mmol), THF (5~10 mL), 100 oC, 48 h. [b] BET surface area calculated over the range P/P0=0.05~0.20. [c] Total pore volume calculated at P/P0=0.99. [d] Average pore size calculated by the BET method. S24 Supplementary Table S4. Textural properties of PCIF-1(M4) after treated in H2O or various organic solvents.a Soaked in solvents SBET [m2 g-1]b Vp [cm3 g-1]c Dav [nm]d H2O 912 0.73 3.20 CH3OH 886 0.68 3.06 CHCl3 843 0.59 2.96 DMF 856 0.57 2.68 DMSO 866 0.65 2.99 [a] The sample PCIF-1(M4) with the surface area of 942 m2 g-1 and pore volume of 0.76 cm3 g-1 was soaked into various solvents for 24 h at the room temperature, and then was collected by filtration, washing and drying for further characterizations. [b] BET surface area calculated over the range P/P0=0.05~0.20. [c] Total pore volume calculated at P/P0=0.99. [d] Average pore size calculated by the BET method. S25 Supplementary Table S5. Hydroxylation of benzene to phenol over various catalysts using O2 as the oxidant. Entry Catalyst Yield of phenol (%) 1 No catalyst, no ascorbic acid Not detected 2 No catalyst, with ascorbic acid 2.3 3 PCIF-1(M8) (0.25 g) 2.2 4 PMoV (0.035 g) 4.6 5 PMoV@PCIF-1 (0.30 g) 12.0 Reaction condition: 0.8 g ascorbic acid, 2.0 mL benzene, 25 mL aqueous acetic acid solution (50 vol%), 2.0 MPa O2, 100 oC, 10 h. S26 Supplementary Table S6. Comparison of catalyst recycling performances of this work with various published heterogeneous catalysts for hydroxylation of benzene with O2. Catalyst Phenol yield (%) Reference V/SiO2 3.7 (one-run) J. Chem. Soc. Perkin Trans. 2, 847-853 (1999). V/Al2O3 8.2 (one-run)a J. Mol. Catal. A: Chem. 184, 215–222 (2002). VOx/CuSBA-15 27 (one-run)b Appl. Catal. A 328, 150-155 (2007). V-SBA-16 30.4 (one-run) Catal. Lett. 142, 619–626 (2012). VxOy@C 9.4/7.0/2.2c Green Chem. 15, 1150-1154 (2013). Cu/Al2O3 2.5/1.4/0.9 J. Mol. Catal. A: Chem. 208, 203-211 (2004). LaOx/HZSM-5d 4.2/3.3/3.6 Top. Catal. 47, 98-100 (2008). CsPMoV2 7.2/5.1/1.3 Ind. Eng. Chem. Res. 44, 1-7 (2005). bipy2PMoV1e 7.8/5.5/4.2/3.7 Chem. Eng. J. 239, 19-25 (2014). PMo9V3@HKUST-1f 7.37/7.04/6.40/6.35 Catal. Commun. 35, 101-104 (2013). POM@MOF@SBA-15 PMoV@PCIF-1 6.0/6.0/5.8/5.9 Micropor. Mesopor. Mater. 195, 87-91 (2014) 12.0/9.3/8.4/6.8 This work [a] 37.6 % V leaching observed. [b] Vanadium was dissolved obviously into the liquid phase. [c] The supported vanadium catalysts suffered from the vast leaching of vanadium. [d] HZSM-5: hydrogen form of ZSM-5 zeolite. [e] bipy: 4,4'-bipyridine. [f] HKUST-1: a stable metal-organic framework (MOF). S27 In order to make a detail comparison, Supplementary Table S6 summarizes the initial phenol yield and recycling performances of the typical previous reported heterogeneous catalysts for hydroxylation of benzene with O2. Up to now, only very few heterogeneous catalysts have been reported so far, and they rarely exhibited both high phenol yield and well reusability. VOx/CuSBA-15 and V-SBA-16 gave the highest phenol yield of more than 20%, but these catalysts could not be recycled (Appl. Catal. A 328, 150-155 (2007); Catal. Lett. 142, 619–626 (2012)). The recently reported POM catalysts including bipy2PMoV1, PMo9V3@HKUST-1 and POM@MOF@SBA-15 gave the improved catalytic recycle performances, but the phenol yields were modest (Chem. Eng. J. 239, 19-25 (2014); Catal. Commun. 35, 101-104 (2013); Microporous Mesoporous Mater. 195, 87-91 (2014)). By comparison, the four-run cycle performance of 12.0/9.3/8.4/6.8% over the catalyst PMoV@PCIF-1 is superior to the previously reported heterogeneous catalytic systems, presenting both relative high phenol yield and well cycle performance at the current research stage. More importantly, to the best of our knowledge, the TON value (136) is much higher than all the previous V-POM-based catalysts for homogeneous or heterogeneous aerobic oxidation of benzene to phenol, further illustrating the high activity of the obtained PMoV@PCIF-1. In a word, the presented catalyst PMoV@PCIF-1 provided both relative high initial phenol yield and well cycle performance. S28