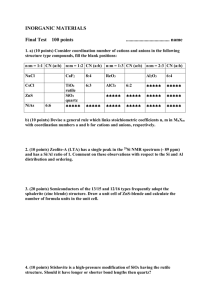

polb23915-sup-0001-suppinfo01

advertisement

SUPPORTING INFORMATION Interfacial Effect on Confined Crystallization of Poly(ethylene oxide)/Silica Composites Weiwei Zhao,1 Yunlan Su,1 Xia Gao,1 Jianjun Xu,2 Dujin Wang1 1 Beijing National Laboratory for Molecular Sciences, Key Laboratory of Engineering Plastics, Institute of Chemistry, Chinese Academy of Sciences, Beijing 100190, China 2 DSM Resolve, P. O. Box 18, 6160 MD, Geleen, the Netherlands 1. Fourier Transformation Infrared Spectroscopy (FTIR) Fourier transform infrared spectroscopy (FTIR Nicolet 6700) in the transmission mode was performed to characterize the interaction between SiO2 and PEO. Spectra were recorded with 64 scans and a resolution of 4 cm–1. Figure S1. FTIR spectra of pure SiO2 -130 (a) and PEO/SiO2 -130 composites with different SiO2 contents (b). The FTIR spectra of pure SiO2-130 are composed of isolated silanols band around 3740 cm–1, inner silanols around 3650 cm–1, hydrogen bonded silanols at 3500–3550 cm–1 which are hidden by adsorbed water and the –CH2– stretching vibrations (ʋ–CH2–) of un-hydrolyzed tetraethoxysilane (TEOS) at 2926 cm–1 and 2853 cm–1.1,2 2. Solid-state 29Si MAS NMR In order to make sure the relative amount of surface groups on SiO2, 29 Si MAS NMR measurement was conducted at Bruker Avance Ш 400 M. Experiments were carried out at the spinning speed of 5 KHz, with pulse length and delay time of 2 µs and 2 s, respectively. Octakis(trimethylsiloxy)silsesquioxane (Q8M8) was taken as a reference. Figure S2. (a) 29Si MAS NMR spectra of pure SiO2. (b) The TGA curves of SiO2 samples recorded under N2 atmosphere at a heating rate of 10 oC/min. As shown in the Figure S2a, all of the 29Si NMR spectra of pure SiO2 are composed of Q2, Q3 and Q4 species which correspond to germinal silanols/ethoxy, single silanols/ethoxy and Si–O–Si skeleton, respectively.3 According to the chemical shift of different species,3 the peak-fitting was applied to calculate the relative ratios of Q2, Q3 and Q4 species, and the results are reported in Table S1. Moreover, in Figure S2a only the curve of SiO2-75 shows an obvious trend to the low field compared with the other three curves, which means that the Q3 species of SiO2-75 consist of a considerable part of ethoxy. In along with the values of α (OH + –OC2H5 %) in Table S1, –OH density of the SiO2 samples is with the following trend: SiO2-75 < SiO2-130 ≈ SiO2-290 ≈ SiO2-520. With the combination of TGA, the silanols density can be estimated as follows:4 OH / nm 2 = 2[ wt (To ) – wt (T f )] N A M ( H 2O) S where wt(To) and wt(Tf) are the weight of the silica particles (wt %) at temperatures To and Tf, respectively, M(H2O) is the molecular weight of the water, NA is Avogadro’s number, and S is the theoretically calculated specific surface area of silica particle. As calculated from Figure S2b, the TGA consequences are in good agreement with NMR results. Table S1. Amounts of various Q species determined from Figure S2a a Samples Q2 (%) Q3 (%) Q4 (%) α (OH + –OC2H5 %)a SiO2-75 2.0 b 24.4 73.6 28.4 SiO2-130 1.6 31.3 67.1 34.5 SiO2-290 2.0 28.9 69.1 32.9 SiO2-520 2.7 27.8 69.5 33.2 α (OH + –OC2H5) means the stoichiometric ratio of the silanols as well as unreacted ethoxy and it can be given by α (OH + –OC2H5) = 2Q2 + Q3.5 b The fitting peak of Q2 in SiO2-75 could not be obtained through peak-fitting analysis. However, the proportion of Q2 can be considered to be about 2 % because the intensity of Q2 peak is almost the same for these four curves. 3. Melting Thermograms of Four PEO/SiO2 Composites Figure S3. The melting thermograms of four composites: (a) PEO/SiO2-75, (b) PEO/SiO2-130, (c) PEO/SiO2-290, and (d) PEO/SiO2-520. References 1 E. F. Vansant, P. Van Der Voort, K. C. Vrancken, Characterization and chemical modification of the silica surface; Elsevier, 1995, Netherlands,. 2 J. P. Gallas, J. C. Lavalley, A. Burneau, O. Barres, Langmuir 1991, 7, 1235–1240. 3 T. I. Suratwala, M. L. Hanna, E. L. Miller, P. K. Whitman, I. M. Thomas, P. R. Ehrmann, R. S. Maxwell, A. K. Burnham, J. Non-Cryst. Solids 2003, 316, 349–363. 4 J. M. Kim, S. M. Chang, S. M. Kong, K. S. Kim, J. Kim, W. S. Kim, Ceram. Int. 2009, 35, 1015–1019. 5 L. Jelinek, P. Dong, C. Rojas-Pazos, H. Taibi, E. S. Kovats, Langmuir 1992, 8, 2152–2164.