1 - Louisiana State University

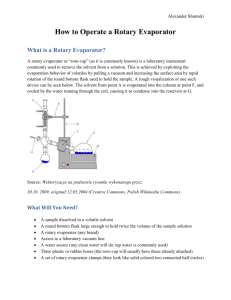

advertisement

Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety 1.0 Location: OES Page 1 of 7 Revision: 00 PURPOSE: Working with hazardous chemicals at high or low pressures requires planning and special precautions. Procedures should be implemented to protect against explosion or implosion through appropriate equipment selection and the use of safety shields. Care should be taken to select glass apparatus that can safely withstand designated pressure extremes. This SOP provides general safety procedures for the use of rotary evaporators in a laboratory setting. 2.0 SCOPE: This procedure applies to all Louisiana State University Personnel that work in a laboratory and have the potential to use a rotary evaporator. It is the intent of this guideline to provide information on the proper use of a rotary evaporator in a laboratory at LSU and afford employee protection while working in a laboratory. 3.0 RESPONSIBILITIES: Only trained and qualified personnel shall be allowed to work in a laboratory at LSU. Each laboratory worker is directly responsible for safe operation of laboratory equipment. Supervisors are responsible for ensuring that personnel are trained to work safely in a laboratory. All laboratory personnel are responsible for reading and understanding this procedure. 4.0 5.0 DEFINITIONS: 4.1 High vacuum - Typically 10-3 millibars or better produced using a vacuum pump. 4.2 Low vacuum – Typically around 30 millibars produced by a water pump REFERENCES: Not Applicable 6.0 MATERIALS and/or EQUIPMENT: Personal Protective Equipment Safety Shielding Rotary Evaporator System 7.0 PROCEDURES: Vacuum work can result in an implosion and the possible hazards of flying glass, spattering chemicals, and fire. Implosion and flying glass can lead to cuts and lacerations. Any piece of DOC # Active Date: Retired Date: Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety Location: OES Page 2 of 7 Revision: 00 glassware under vacuum has the potential to do harm following implosion. The energy imparted to flying fragments is directly proportional to the volume of the glass vessel evacuated It is a common misconception that so called "high vacuum" (typically 10-3 mbars or better) systems present a significantly greater hazard than everyday vacuums produced by e.g. a water pump (around 30 millibars). These may differ by four orders of magnitude but the forces to which the glassware is subjected is essentially the same. 7.1 General Precautions For Working With Rotary Evaporator Systems 7.1.1 Personal protective equipment, such as safety glasses or chemical goggles, face shields should be used to protect against the hazards of vacuum procedures. 7.1.2 Always place a safety screen between the operator and glassware under increased or reduced pressure. 7.1.3 Only handle these types of equipment in the presence of others. 7.1.4 Use heavy-wall rubber tubing only. Thin-wall rubber tubing and plastic tubing are not suitable because they collapse leaving a partially evacuated closed system. 7.1.5 Although glass vessels are frequently used in vacuum systems, they can explode or implode violently, either spontaneously from the strain or from an accidental blow. Therefore, pressure and vacuum operations in glass vessels should be conducted behind adequate shielding. Glass vessels should be designed for the operation intended, and should be visually checked for star cracks, scratches, or etching marks before each use. 7.1.6 Flasks with volumes of 1 liter or larger and the cooling condenser must be enclosed in tape or plastic mesh to restrain fragments in case of implosion. 7.1.7 Glass dewars should be fully wound in tape or preferably enclosed in a metal container. 7.1.8 The rotation speed and application of vacuum should be done gradually when using a rotary evaporator. 7.1.9 Do not hold onto the sample whilst it is revolving: failure of the flask could result in serious lacerations to the hands. 7.1.10 Slowly admit air back into the apparatus after evaporation of the solvent is complete. 7.1.11 Clean the apparatus after use. Do not mix halogenated and non-halogenated solvents in the receiver. DOC # Active Date: Retired Date: Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety 7.2 Location: OES Page 3 of 7 Revision: 00 Low Vacuum Rotary Evaporators A low vacuum (typically around 30 millibars) rotary evaporator system uses a water aspirator reduce the pressure so that solvents can be separated. The use of cold traps is dependent on the solvent. 7.2.1 Hook up tubing as between the vacuum source and the rotary evaporator. 7.2.2 Make sure the round bottom (RB) flask is twice the volume as your sample volume. 7.2.3 Keep the inside of all tubing as large as possible so the vacuum is strong. Suggested vacuum tubing size is approximately 3/16” wall thickness x 5/16” ID. 7.2.4 Fill water bath with deionized water, set temperature and turn on. 7.2.5 Put solvent “catch pot” in place. 7.2.6 Fill ice bucket and place under catch pot to remove as many solvents as possible from condenser. 7.2.7 If required, hook up the solvent trap and fill it with ice. 7.2.8 Make sure tubing from the condenser carrying the warmed water is in the drain. 7.2.9 Fill cooling coils inside condenser and leave cooling water flowing if you’re ready to evaporate a sample (Use chiller if you have one). 7.2.10 Make sure vacuum valve at top of the condenser is “open” so you’re not pulling a vacuum yet when you put on your sample flask. 7.2.11 Attach the RB sample flask to the condenser and fasten into place with a clamp. 7.2.12 Start rotation of flask slowly and gradually increase speed. 7.2.13 Slowly close the vacuum valve at the top of the condenser – watch for bubbles in your sample! Adjust vacuum as needed. 7.2.14 Once the sample has stabilized, lower the flask into the water bath. 7.2.15 Continue the process as long as necessary. 7.2.16 If you need to break the vacuum to the pump to discard solvent from the trap or add ice to the solvent trap, open the valve and leave the vacuum pump running. Discard solvent/add ice, shut valve and continue with rotary evaporation of sample. 7.2.17 When completely done with evaporating all samples, open valve to break vacuum and continue to run water at least 5 minutes. 7.2.18 Solvents should be poured into proper bottles and labeled for waste collection. DOC # Active Date: Retired Date: Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety 7.3 Location: OES Page 4 of 7 Revision: 00 High Vacuum Rotary Evaporation Set-Up A high vacuum (typically 10-3 millibars or better) rotary evaporator system include the use of a vacuum pump or a house vacuum system to reduce the pressure so that high boiling solvents and be separated. The system also requires the use of cold traps to prevent solvent contamination of the vacuum source. 7.3.1 Hook up tubing as between the vacuum source and the rotary evaporator. Be sure to note the in and out labels on the solvent trap. 7.3.2 Make sure the round bottom (RB) flask is twice the volume as your sample volume. 7.3.3 Elevate the vacuum pump above the traps to aid in keeping the solvents out of the pump. 7.3.4 Be sure to add an open/close valve between the last trap and the vacuum pump to aid in solvent removal from traps 7.3.5 Keep the inside of all tubing as large as possible so the vacuum is strong. Suggested vacuum tubing size is approximately 3/16” wall thickness x 5/16” ID. 7.3.6 Using dry ice is the recommended method of keeping the atmosphere cold to condense the solvent. If you choose to use an ice, rock salt (used for making ice cream) and water slurry please test the system first to see how many traps you must use to keep solvent out of the vacuum pumps as that can damage the pumps over time. A handy way to check this would be a check of the last sidearm flask before the pump and see if any solvent has precipitated. Also place a piece of clear Tygon tubing on the out vent of the vacuum pump and check for solvent droplets that may have formed. If you are using glass as part of the connection in a side-arm flask remember to use glycerin to wet the glass. Wear gloves to protect your hands and hold the glass next to the point you are applying pressure when putting the vacuum tubing on. 7.3.7 7.4 The temperature of dry ice is -78.5 ºC. High Vacuum Rotary Evaporation Procedure: 7.4.1 Fill water bath with deionized water, set temperature and turn on. 7.4.2 Put solvent “catch pot” in place. 7.4.3 Fill ice bucket and place under catch pot to remove as many solvents as possible from condenser. 7.4.4 DOC # Hook up dry ice trap. Active Date: Retired Date: Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety Location: OES Page 5 of 7 Revision: 00 7.4.5 Fill trap with dry ice or flaked ice and rock salt (if known to work). 7.4.6 Add a second and even a third side-arm flask “trap” between dry ice trap and vacuum pump if you are seeing condensation in the clear tubing coming out of the vacuum pump. 7.4.7 Place secondary ± tertiary “traps” into an ice bucket to catch any additional solvent fumes carried past the first trap. 7.4.8 Make sure tubing from the condenser carrying the warmed water is in the drain. 7.4.9 Fill cooling coils inside condenser and leave cooling water flowing if you’re ready to evaporate a sample. (Use chiller if you have one.) 7.4.10 Make sure vacuum valve at top of the condenser is “open” so you’re not pulling a vacuum yet when you put on your sample flask. 7.4.11 Attach the RB sample flask to the condenser and fasten into place with a clamp. 7.4.12 Start rotation of flask slowly and gradually increase speed. 7.4.13 Slowly close the vacuum valve at the top of the condenser – watch for bubbles in your sample! Adjust vacuum as needed. 7.4.14 Once the sample has stabilized, lower the flask into the water bath. 7.4.15 Continue the process as long as necessary. 7.4.16 If you need to break the vacuum to the pump to discard solvent from the trap or add ice to the dry ice trap, open the valve and leave the vacuum pump running. Discard solvent/add ice, shut valve and continue with rotary evaporation of sample. 7.4.17 When completely done with evaporating all samples, open valve to break vacuum from pump; disconnect tubing from inlet of vacuum pump and allow pump to run at least 5 minutes to dry out any droplets of moisture that might be inside it. 7.4.18 Shut off vacuum pump after 5 minutes. It is possible to plug the vacuum pump into a timer so that the pump is turned if you forget to watch the time. 7.4.19 Solvents should be poured into proper bottles and labeled for waste collection. 7.5 Use of Flaked Ice Follow the SOP for general rotary evaporation setup and procedure. This test procedure is to verify whether you can use flaked ice (“crushed ice”) rather than dry ice in your rotary evaporation setup with your particular solvent(s). It will also indicate how many ice DOC # Active Date: Retired Date: Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety Location: OES Page 6 of 7 Revision: 00 traps you need with your particular solvent(s). This MUST be done with each different solvent or a change in temperature with the same solvent. 7.5.1 Ice the catch pot. This MUST be done. It has been found that approximately 1/3 of the solvent goes past one trap on to the pump/drain when the catch pot is NOT iced. 7.5.2 Place ice and rock salt inside the “dry ice” trap. 7.5.3 Run your rotary evaporator and watch for solvent collection in the catch pot, and dry ice trap. Also watch for any moisture droplets forming at the outlet of the vacuum pump. 4. If you have ANY moisture at the outlet of the vacuum pump, you MUST add another ice trap. 7.5.4 While adding the additional trap, be sure and disconnect the inlet tubing to the vacuum pump and let it run to dry it out. 7.5.5 Add a side-arm flask “trap” between the dry ice trap and vacuum pump. 7.5.6 Place “trap” into an ice container to catch any additional solvent fumes carried past the first trap. 7.5.7 If moisture is gone from outlet of pump, connect everything and you’re ready to run your rotary evaporator again. 7.5.8 Watch for moisture droplets forming again at the outlet of the vacuum pump. 7.5.9 If you still have moisture (solvent) droplets forming at the outlet of the vacuum pump after icing the catch pot, and having two ice traps between the condenser and the vacuum pump, then you have no choice but you MUST use dry ice rather than flaked ice to make it cold enough to chill your particular solvent fumes. 8.0 CONTINGENCIES: 8.1 In case of a fire, explosion, or gas leak evacuate individuals from the area and call the emergency response (911). Notify supervision and adjacent personnel as quickly as possible. Observe appropriate procedures for personal injury or fire as provided in OES Web site. 8.2 In case of a chemical spill, alert others in the immediate vicinity and notify your supervisor. Determine the severity of the spill and proceed as appreciate. Small spills may be cleaned up by laboratory personnel. For large spills, notify OES (578-5640) and Campus Police (911 or 578-3231). If possible to do so safely (without risk of over- DOC # Active Date: Retired Date: Standard Operating Procedure LABORATORY ROTARY EVAPORATORS Investigator: General Safety Location: OES Page 7 of 7 Revision: 00 exposure), take action to stop the release. Ensure that extraneous personnel remain at a safe distance until the spill is completely cleaned-up 9.0 REVIEWS AND REVISIONS: This procedure shall be reviewed for compliance and effectiveness and revised as necessary on an annual basis. 10.0 ATTACHMENTS and REFERENCE FORMS: Not Applicable DOC # Active Date: Retired Date: