SMAW STUDY GUIDE 2 True/False Indicate whether the statement

advertisement

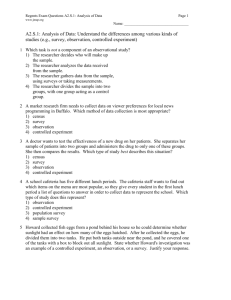

SMAW STUDY GUIDE 2 True/False Indicate whether the statement is true or false. ____ 1. Welding with the current set too high results in poor fusion and poor arc stability. ____ 2. If the current is set too low or too high, you should change the settings during welding. ____ 3. As the weld progresses, the electrode becomes shorter. ____ 4. Shorter arcs are best suited for use on thin metal or thin-to-thick metal joints. ____ 5. The weave pattern selected for a flat butt joint is not as critical as the pattern selection for other joints and positions. ____ 6. Body position changes should never be made during electrode changes. ____ 7. Electrodes with cellulose-based fluxes do not have heavy slags. ____ 8. Electrodes with mineral-based fluxes should be the first choice. ____ 9. As the fillet weld is made on a lap joint, the buildup should be less than the thickness of the plate. ____ 10. A welded tee joint can be strong if it is welded on both sides, even without having deep penetration. Multiple Choice Identify the choice that best completes the statement or answers the question. ____ 11. Welding with the current set too high results in ____. a. slag or gas inclusions b. little or no penetration c. poor fusion and poor arc stability d. excessive spatter ____ 12. If the current is set too high, the electrode covering is discolored more than ____ from the end of the electrode. a. 1/16 in. to 1/8 in. b. 1/8 in. to 1/4 in. c. 1/4 in. to 1/2 in. d. 1/2 in. to 3/4 in. ____ 13. The selection of the correct size of welding electrode is determined by ____. a. the arc length b. the weld pool size and penetration c. the current amperage d. the thickness and size of the metal ____ 14. Large diameter electrodes may overheat the metal if ____. a. they are used with thick or large pieces of metal b. they are used with aluminum c. they are used with thin or small pieces of metal d. they are used with exotic alloys ____ 15. To correct a(n) ____ problem, a welder can use a smaller electrode at a lower current setting. a. overheating b. spatter c. penetration d. slag buildup ____ 16. The ____ is the distance the arc must jump from the end of the electrode to the plate or weld pool surface. a. arc length b. root gap c. weave pattern d. weld width ____ 17. An arc will jump ____. a. to the weld pool b. to the root gap c. the closest metal conductor d. the electrode ____ 18. If arc length is shortened, metal transferring across the gap may short out the electrode, causing it to ____. a. produce excessive slag b. stick to the plate c. burn through the metal d. produce excessive spatter ____ 19. To prevent ____ use as little leading angle as possible. a. spatter b. burnthrough c. poor penetration d. cold lap and slag inclusions ____ 20. Some electrodes may not remove the deposits ahead of the molten weld pool, resulting in ____. a. discontinuities within the weld b. burnthrough c. excessive spatter d. electrode discoloration ____ 21. A ____ electrode angle pushes the molten metal away from the leading edge of the molten weld pool toward the back where it solidifies. a. leading b. right c. trailing d. straight ____ 22. The ____ weave pattern for flat position welds on butt, tee, and outside corner joints. a. circular b. square c. “J” d. “T” ____ 23. The ____ pattern works well on flat lap joints, all vertical joints, and horizontal butt and lap welds. a. circular b. square c. “J” d. “T” ____ 24. The ____ pattern is good when there is a large gap to be filled when both pieces of metal are nearly the same size and thickness. a. circular b. square c. “J” d. “T” ____ 25. The straight step pattern can be used for ____. a. fillet welds b. deep groove welds c. stringer beads d. filling in the weld toe ____ 26. In ____ pattern, the smallest quantity of metal is molten at one time as compared to other patterns. a. circular b. “J” c. “C” d. straight step ____ 27. Students will find it easier to start with ____ joints. a. tee b. lap c. outside corner d. butt ____ 28. ____ welds are more difficult to perform than most welds. a. Horizontal tee b. Horizontal lap c. Overhead d. Horizontal butt ____ 29. ____ electrodes have a forceful arc with little slag left on the weld bead. a. E6010 and E6011 b. E6012 and E6013 c. E7016 and E7018 d. E7017 and E7019 ____ 30. ____ electrodes have a mineral-based flux with very heavy slag left on the weld bead. a. E6010 and E6011 b. E6012 and E6013 c. E7016 and E7018 d. E7017 and E7019 ____ 31. ____ have rutile-based fluxes with a thick slag left on the weld bead. a. E6010 and E6011 b. E6012 and E6013 c. E7016 and E7018 d. E7017 and E7019 ____ 32. Electrodes with ____ are easier to control and are used for flat stringer beads and butt joints. a. cellulose-based fluxes b. rutile-based fluxes c. mineral-based fluxes d. silicon-based fluxes ____ 33. Electrodes with ____ do not have heavy slags and are suitable for tee and lap joints. a. cellulose-based fluxes b. rutile-based fluxes c. mineral-based fluxes d. silicon-based fluxes ____ 34. ____ are used to set the machine amperage and for buildup of surfacing applications. a. Tack welds b. Stringer beads c. Fillet welds d. Lap welds ____ 35. The space between plates in a square butt joint is called the ____. a. butt gap b. weld gap c. root gap d. penetration Completion Complete each statement. 36. A weld bead made at a(n) ____________________ amperage setting is wide and flat with deep penetration, and produces excessive spatter and is mostly hard. 37. A(n) _________________________ is a large piece of metal used to absorb excessive heat. 38. A(n) ____________________ electrode angle pushes the molten metal and slag ahead of the weld. 39. Electrodes with _________________________ fluxes are easier to control and are used for flat stringer beads and butt joints. 40. A straight weld bead on the surface of a plate with little or no side-to-side electrode movement is known as a(n) _________________________. 41. A(n) _________________________ joint is made by tack welding two flat pieces of plate together. 42. A(n) _________________________ joint is made by placing the edges of the plate evenly, with no gap between the plates. 43. A(n) ______________________________ joint is made by placing plates at a 90 degree angle to each other, with the edges forming a V groove. 44. A(n) ____________________ joint is made by overlapping the edges of the two plates, and can be welded on one side or both sides with a fillet weld. 45. A(n) ____________________ joint is made by tack welding one piece of metal on another piece of metal at a right angle. Short Answer 46. Discuss the effects of setting the current too low or too high. 47. Describe how to determine if a weld is too hot. 48. Describe the effect of arc length on the weld. 49. Describe the proper body position for a welder. 50. Compare cellulose- and rutile-based fluxes. SMAW STUDY GUIDE 2 Answer Section TRUE/FALSE 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: F F T T T F T F F T PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: 1 1 1 1 1 1 1 1 1 1 REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: 71 73 74 74 77 79 79 80 93 97 PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: PTS: 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: REF: 72 72 73 73 73 74 74 74 75 75 76 77 78 78 78 78 79 79 79 79 79 79 79 80 82 MULTIPLE CHOICE 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: ANS: COMPLETION D B D C A A C B D A C A C B C D D D A C B B A B C 36. ANS: high PTS: 1 37. ANS: chill plate REF: 72 PTS: 1 38. ANS: leading REF: 73 PTS: 1 39. ANS: rutile-based REF: 75 PTS: 1 REF: 79 40. ANS: stringer bead PTS: 1 41. ANS: square butt REF: 80 PTS: 1 42. ANS: edge weld REF: 82 PTS: 1 REF: 85 43. ANS: outside corner PTS: 1 44. ANS: lap REF: 90 PTS: 1 45. ANS: tee REF: 93 PTS: 1 REF: 97 SHORT ANSWER 46. ANS: Each welding electrode must be operated in a specified current (amperage) range. Welding with the current set too low results in poor fusion and poor arc stability. The weld may have slag or gas inclusions because the molten weld pool was not fluid long enough for the flux to react. Little or no penetration of the weld into the base plate may also be evident. With the current set too low, the arc length is very short. A very short arc length results in frequent shorting and sticking of the electrode. The core wire of the welding electrode is limited in the amount of current it can carry. As the current is increased, the wire heats up because of electrical resistance. This preheating of the wire causes some of the chemicals in the covering to be burned out too early. The loss of the proper balance of elements causes poor arc stability. This condition leads to spatter, porosity, and slag inclusions. An increase in the amount of spatter is also caused by longer arc lengths. The weld bead made at a high amperage setting is wide and flat with deep penetration. The spatter is excessive and is mostly hard. The spatter is called hard because it fuses to the base plate and is difficult to remove. The electrode covering is discolored more than 1/8 in. (3 mm) to 1/4 in. (6 mm) from the end of the electrode. Extremely high settings may also cause the electrode to discolor, crack, glow red, or burn. PTS: 1 REF: 71-72 47. ANS: To determine if a weld is too hot, watch the shape of the trailing edge of the molten weld pool. Rounded ripples indicate the weld is cooling uniformly and that the heat is not excessive. If the ripples are pointed, the weld is cooling too slowly because of excessive heat. Extreme overheating can cause a burnthrough. Once a burnthrough occurs, they are hard to repair. PTS: 1 REF: 73 48. ANS: The arc length is the distance the arc must jump from the end of the electrode to the plate or weld pool surface. As the weld progresses, the electrode becomes shorter as it is consumed. To maintain a constant arc length, the electrode must be lowered continuously. Maintaining a constant arc length is important, as too great a change in the arc length will adversely affect the weld. As the arc length is shortened, metal transferring across the gap may short out the electrode, causing it to stick to the plate. The weld that results from a short arc is narrow and has a high buildup. Long arc lengths produce more spatter because the metal being transferred may drop outside of the molten weld pool. The weld is wider and has little buildup. PTS: 1 REF: 74 49. ANS: The welder should be in a relaxed, comfortable position before starting to weld. A good position is important for both the comfort of the welder and the quality of the welds. Welding in an awkward position can cause welder fatigue, which leads to poor welder coordination and poor-quality welds. Welders must have enough freedom of movement so that they do not need to change position during a weld. Body position changes should be made only during electrode changes. PTS: 1 REF: 79 50. ANS: The cellulose- and rutile-based groups of electrodes have characteristics that make them the best electrodes for starting specific welds. The electrodes with the cellulose-based fluxes do not have heavy slags that may interfere with the welder’s view of the weld. This feature is an advantage for flat tee and lap joints. Electrodes with the rutile-based fluxes (giving an easy arc with low spatter) are easier to control and are used for flat stringer beads and butt joints. PTS: 1 REF: 79