18th European Symposium on Computer Aided Process Engineering – ESCAPE 18

Bertrand Braunschweig and Xavier Joulia (Editors)

© 2008 Elsevier B.V./Ltd. All rights reserved.

Integrated design and control of processes coupling

exothermic and endothermic reactions

Pietro Altimaria and Costin Sorin Bildeab

a

b

Delft University of Technology, Julianalaan 136, 2628BL, Delft, The Netherlands

University “Politehnica” of Bucharest, 1-7 Polizu, 011061 - Bucharest, Romania

Abstract

The nonlinear behavior of plantwide systems, where the endothermic first-order

reaction A → R+Q and the exothermic second-order reaction B+Q → P

simultaneously take place, is investigated. As the physical properties of the species

involved vary, possible flowsheets are identified and feasible control strategies are

suggested. Bifurcation analysis is performed by varying the set-point variables. Steady

state multiplicity is detected leading to complex behavior. Implications on plantwide

control are discussed and guidelines are provided which enable to select values of setpoint variables in a way that guarantees feasible operation. Singularity theory is

exploited to investigate the influence of reactor design parameters on plant operability

and complex multiplicity patterns with a maximum of five coexisting steady states and

isolated solution branches are predicted.

Keywords: Reaction coupling; Recycle systems; Nonlinear dynamics; Design; Control.

1. Introduction

As result of the increasing demand for sustainable process solutions, several efforts

have been carried out, over the past decades, towards the development of effective

process intensification technologies. In this framework, coupling endothermic and

exothermic reactions in a single reactor unit has been extensively recognized to offer

several advantages [1]. It guarantees in general increased thermal efficiency and, for

reversible chemical reactions, can lead to increased reactor equilibrium conversion and

increased reaction rate due to equilibrium displacement. As a result, energy savings and

reduced reactor size are achieved. Some examples demonstrating the effectiveness of

this idea are in situ hydrogen combustion in oxidative dehydrogenation [2], coupling

propane combustion and endothermic thermal cracking of propane to ethylene and

propylene [3], and coupling methane steam reforming with catalytic oxidation of

methane in partial oxidation reactors [4].

While enhancing reactor performances, performing endothermic and exothermic

chemical reactions in a single unit may lead to increased complexity of the external

plant, making necessary additional separation and recycles. In practice, energy savings

and reduced reactor investments must outweigh the cost of required additional units.

Furthermore, operational and control difficulties arising from a more complex behavior

should be taken into account to assess feasibility of this operation mode. To this regard,

we remark that introducing recycle streams is recognized to be source of nonlinear

phenomena [5, 6]. However, despite the great interest towards the development of

intensified plant solutions, the behavior of reactor separation recycle systems coupling

exothermic and endothermic chemical reactions has not been studied.

In this work, we investigate the steady state behavior of Reactor-Separation-Recycle

(RSR) systems simultaneously carrying on the following reactions:

2

P. Altimari and C. S. Bildea

A → R+Q, endothermic, first order

B+Q → P, exothermic, second order

This reaction scheme has been chosen as representative of a large class of chemical

processes, where the heat necessary to perform a desired endothermic reaction is

provided by conversion of a byproduct Q in a secondary exothermic reaction.

The paper is structured as follows. Flowsheets which are possible, depending on the

physical properties of the species involved, are analyzed. Then, model equations are

presented in dimensionless form. Finally, the steady state behavior of the plantwide

system is described and operational difficulties are addressed. Final remarks end the

paper.

2. Conceptual design and plantwide control

We consider a RSR where the reactants A and B are fed to the plant whereas the amount

of Q required to perform the exothermic reaction is provided by the endothermic one.

Unconverted reactants A, B, Q are totally recovered and recycled to the reactor, while

products P and R are removed from the plant. Under these assumptions, mole balance

equations governing the steady state behavior of the RSR system can be written as

follows:

f A,1 f A,0 A 0

(1)

f B ,1 f B ,0 B 0

(2)

f Q ,1 Q 0

(3)

where fK,0 and fK,1 (K = A, B, Q) denote the dimensionless molar flow rates of the

species K at the plant inlet and reactor inlet, respectively. A B, Q are functions

describing the dependence of recycle flow rates on reactor-inlet flow rates, reactor

parameters and separation performance. Five unknown lumped variables are to be

determined from three equations. Hence, two consistent specifications must be provided

to solve the balance equations.

In practice, these specifications can be achieved by flow or concentration control loops.

However, since concentration measurements are expensive and unreliable, controlling

flow rates is, in general, the preferred option. For this reason, we focus on control

strategies which can be applied without using concentration measurements.

The number and the components of the recycle streams are determined by the physical

properties of the species involved. Based on this, the set of possible flowsheets of the

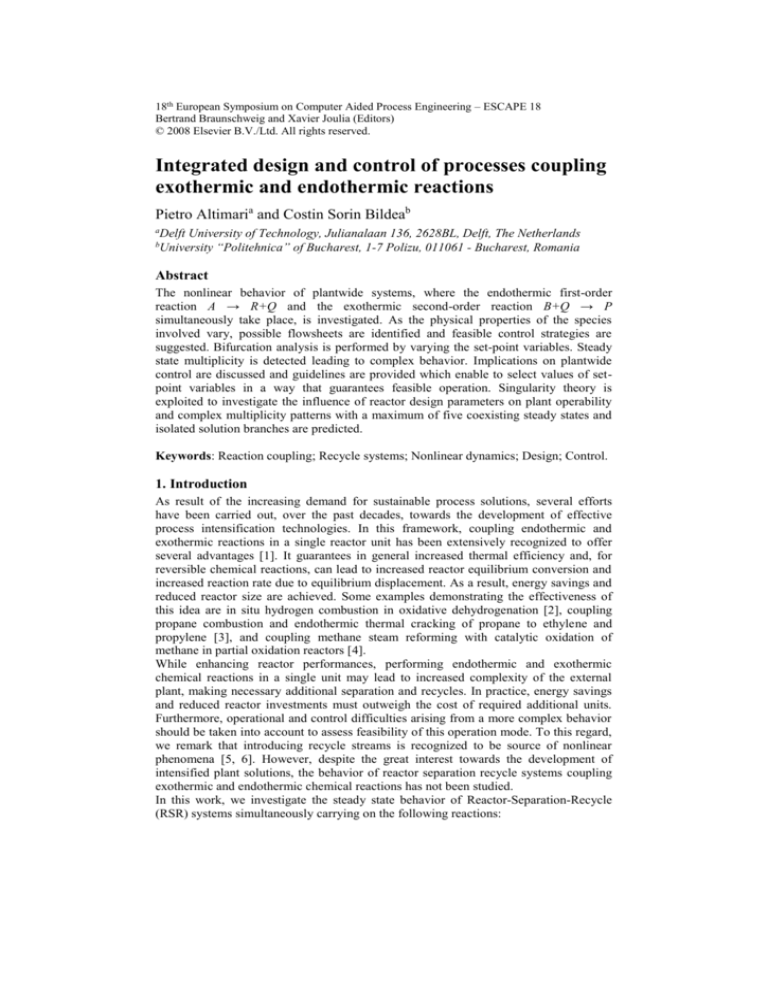

RSR system is structured according to the classes described in Fig.1. Based on the

analysis of the flowsheet structures presented in Fig.1, eight admissible control

strategies have been identified. While the steady state behavior of the RSR system was

analyzed for all these control structures, we present in this paper only results concerning

a control strategy fixing the flow rates of the endothermic reactant A and exothermic

reactant B at the reactor inlet. This strategy gives rise to the following additional

equations:

f A,1 m ; f B ,1 p

(4)

Integrated design and control of processes coupling exothermic and endothermic

reactions

3

where m and p are the set-points of the flow rate control loops. This is, in general, the

recommended strategy when coping with RSR systems because it removes the effect of

recycling reactants. As a result, the system is expected to behave as a plug flow reactor

followed by a separation section, which exhibits a unique steady state. We show that,

for the reaction scheme here considered, a complex behavior still occurs.

(a)

(b)

A

A,B

A,B

P,R

Reactor

Separation

A,B

P,R

Reactor

Separation

B

Q

Q

(c)

(d)

B,Q

A,Q

A,B

P,R

Reactor

A,B

Separation

A

P,R

Reactor

Separation

B

Figure 1 Classification of the flowsheets of the RSR system which are possible as the physical

properties of the species involved varies.

3. The mathematical model

In this section, we present the mathematical model governing the steady state behavior

of the RSR system. The reactor-inlet temperature is fixed by feedback control of a heat

exchanger placed upstream of the reactor. A plug flow model is used to describe the

steady state behavior of the reactor. Arrhenius dependence of the kinetic constants on

temperature is assumed. Mass and energy balance equations describing the steady state

behavior of the RSR system write as follows:

df A

f A

Da exp

d

1 f

G2,1 f Q f B

df B

DaK 2,1 exp

2

d

1 f

G2,1 fQ f B

d Da

f A

K 2,1 H 2,1 B exp

2 B exp

( c )

d

f

1 f

1 f

f Q f Q , 1 f A ,1 f A f B ,1 f B ; f R f A , 1 f A ; f P f B , 1 f B

f f A f B fQ f P f R

(5)

(6)

(7)

(8)

(9)

f A (0) f A,1 ; f B (0) f B,1 ; (0) 0;

(10)

f A (1) A 0 ; f B (1) B 0 ; f Q (1) Q 0

(11)

f A ,0 A f A ,1 0 ; f B , 0 B f B , 1 0 ; Q f Q ,1 0

(12)

4

P. Altimari and C. S. Bildea

The variables appearing in the mathematical model are the dimensionless axial

coordinate , the dimensionless flow rates f, the temperature along the reactor, and the

dimensionless recycle flow rates K. The model parameters are the Damkohler number

Da, the ratio between the kinetic constants K2,1, the dimensionless adiabatic temperature

rise B, the ratio between the reactions enthalpies H2,1, the ratio between the activation

energies G2,1, the dimensionless heat transfer capacity , the dimensionless cooling

temperature c.

4. Influence of the set point variables m and p

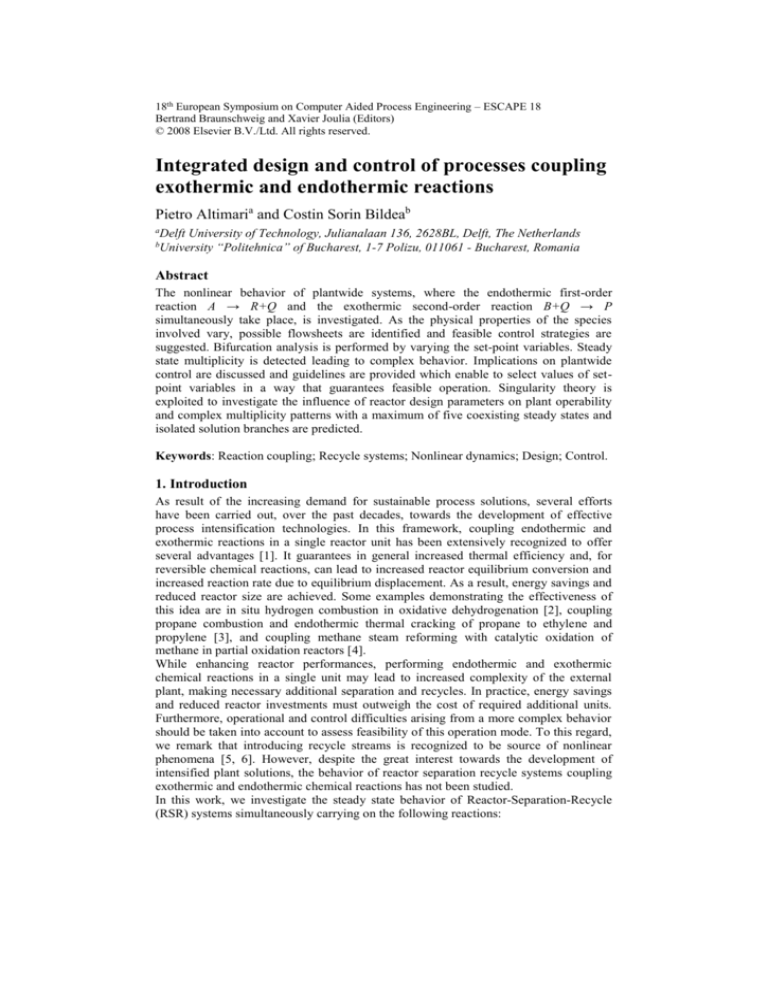

Typical steady state solution regimes of the RSR system controlled by strategy (4) are

described in Fig.2 as m varies, at p = 2.5. The reactor conversion of A is employed as

variable representative of the state of the system. Four saddle-node bifurcation points

S1, S2, S3, and S4 are predicted.

1,0

S1

xA

p = 2.5

S2

0,5

S4

S3

0,0

0

1

2

3

m1

4

m

Figure 2 Steady state solution diagram of the RSR system controlled by strategy (4), with m as

bifurcation parameter. (Da = 2.5, K2,1 = 2.5, B = 0.3,

= 12.5, G2,1 = 2.5, H2,1 = 4.5, c =

0).

A unique steady state is found at low m values. As m is increased, three coexisting

steady states are detected between S1 and S2. In this range, two coexisting regimes

exhibit very close conversion values resulting barely distinguishable in Fig.2. At larger

m values, a unique steady state is detected in the range delimitated by S2 and S3. As m is

further increased, three coexisting steady states arise between S 3 and S4. After the

saddle-node bifurcation point S4, a unique steady state is detected at m values lower than

m1. Increasing m in this range, the reactor conversion becomes smaller and smaller and

approaches zero in the limit m →m1. No feasible steady states are detected at larger m

values.

It is remarkable to observe that feasible steady states are always found at m values lower

than m1. Hence, m1 can provide useful indications to select m values guaranteeing

feasible operation. Analytic prediction of m1 is possible by observing that the recycle of

Q becomes infinitely large as m → m1. To verify it, it is sufficient to note that the

reactor conversion of A approaches zero as m → m1. Since finite amounts of A and B are

fed to the reactor, this can be only due to infinite recycle of Q. As the recycle of Q

becomes infinitely large and reactor conversion approaches zero, concentrations and

temperature are constant along the reactor. Hence, the reactor behaves as a CSTR

Integrated design and control of processes coupling exothermic and endothermic

reactions

5

operated at the feed temperature. For this reason, the dependence of m1 on system

parameters can be predicted by replacing the plug-flow reactor model (5) - (9) by a

CSTR model and solving it jointly with the condition xA=0. This gives the following

inequality guaranteeing the existence of feasible steady states:

m

K 2,1

p

(13)

where the equality holds at m = m1.

Based on (13), a limit reactor-inlet flow rate of B, p1 = m/K2,1, can be equivalently

determined. Once m is given, feasible steady states are guaranteed to exist for p > p1.

5. Influence of Da and

In this section we investigate the influence of reactor parameters on plant operability.

With this objective, we analyze the evolution of the steady state solution diagram of the

controlled RSR system, with m as bifurcation parameter, as the Damkohler number Da

and the dimensionless heat transfer capacity are varied.

When the RSR system is controlled by strategy (4), hysteresis, isola, and double limit

varieties are computed, dividing the Da - space in twelve regions (Fig.3) characterized

by qualitatively different bifurcation diagrams (Fig.4).

12

Isola

(iii)

10

(vii)

Double limit

1

(v)

Hysteresis

(vi)

(iv)

8

0

2,1

2,2

2,3

(x)

(xi)

6

(i)

4

(ii)

(ix)

(vii)

2

(xii)

(viii)

(iii)

(iii) - (vi)

0

1

2

3

4

Da

Figure 3 Classification of the steady state behaviors of the RSR system controlled by strategy (4).

Bifurcation diagrams corresponding to regions (i) - (xii) are displayed in Figure 4 (K2,1 = 2.5, B =

0.3, = 12.5, G2,1 = 2.5, H2,1 = 4.5, p = 1.5, c = 0).

As reactor parameters vary, complex multiplicity patterns with a maximum of five

coexisting steady states and separated solution branches are observed (Fig.4). Parameter

values belonging to region (i) should be, in principle, recommended, because they

guarantee a unique steady state leading to safe operation. However, it must be noted

that, in this region, reactor conversion is low resulting in large recycles. To explain it, it

is sufficient to observe that region (i) mainly extends at low Damkholer values and high

heat transfer capacities. For this reason, it might be advantageous to select reactor

parameter values in different regions covering a large area of the parameter plane Da -

(for example region (ii) or (x)). Although steady state multiplicity is invariably

experienced in regions (ii)-(xii), the analysis provided in sec.(3) can enable the selection

of m and p in a way that guarantees safe operation.

6

P. Altimari and C. S. Bildea

1.0

S1

(i)

S1

(ii)

S1

S2

S2

S3

xA

S3

S2

S2

0.5

S2

S4

S4

S3

S3

(iii)

(iv)

0.0

S1

1.0

S1

S2

S1-S2

S1

S2

S6

xA

S5

0.5

S5

S6

S3

S2

S6

S6

S3

S2

S6

S2

S5

S4

S5

S3

(vi)

S4

S4

S4

S3

(v)

S1

S5

S3

(vii)

(viii)

0.0

1.0

S1-S2

S1

S1

S1

S1-S2

S4

S5

S6

S3

S2

xA

xA

S2

0.5

S4

S2

S3

S4

(x)

(ix)

S3

(xi)

(xii)

0.0

0

1

2

3

m

4

5 0

1

2

3

m

4

5 0

1

2

3

m

4

5 0

1

2

3

4

5

m

Figure 4. Qualitatively different steady state solution diagrams of the RSR system controlled by

strategy (4) corresponding to regions (i) - (xii) displayed in Fig.3.

6. Conclusions

The steady state behavior of RSR systems, where the first order endothermic reaction A

→ R + Q and the second order exothermic reaction B + Q → P simultaneously take

place, was addressed. Flowsheets which are possible, as the physical properties of the

species involved vary, were classified. In this contribution, results concerning the

behavior of the system where the flow rates of the reactants A and B at the reactor inlet

are on flow control were presented.

Bifurcation analysis was performed as the set points of the flow control loops are varied

and feasibility boundaries for the reactor-inlet flow rates of A and B were analytically

predicted. The influence of reactor model parameters on the steady state behavior of the

RSR system was also addressed. Singularity theory was exploited to divide the

Damkholer number – reactor dimensionless heat transfer capacity space in regions

characterized by qualitatively different bifurcation diagrams. Isola, double limit and

cusp varieties were computed and twelve steady state solution diagrams exhibiting a

maximum of five coexisting solution regimes and separated branches were presented.

Our analysis shows that RSR systems coupling exothermic and endothermic reactions

exhibit complex steady state behavior. The reaction scheme considered in this work

involves three reactants, while the plantwide control structure allows fixing only two

degrees of freedom. Since it is impossible to completely remove the effect of material

recycle, no control structure allows to rule out the possibility of state multiplicity.

References

[1] Towler, G., Lynn, S., (1994), Chem. Eng. Sci., 49, 2585.

[2] Grasselli, R., Stern, D., L., Tsikoyiannis, J., G., (1999), Appl. Cat. A-Gen., 189, 1.

[3] Chaudhary, V., R., Rane, V., H., Rajput, A., M., (2000), Ind. Eng. Chem. Res., 39, 904.

[4] De Groote, A., M., Froment, G., F., (1996) Appl. Cat. A-Gen., 138, 245.

[5] Pushpavanam, S., Kienle, (2001), A., Chem. Eng. Sci., 56, 2837.

[6] Kiss, A., A., Bildea, C., S., Dimian, A., C., Iedema, P., D., (2003), Chem. Eng. Sci., 57, 535.