Ass4Ans

advertisement

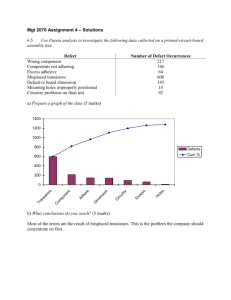

Mgt 2070 Assignment 4 – Solutions 6.11 Develop a Pareto analysis of the following causes of delay in a production process. Reason for Delay Test equipment down Delay in inspection Inadequate parts Lack of personnel available Awaiting engineering decision No schematic available Frequency 22 15 40 3 10 11 To develop the Pareto analysis, we need to rank each reason by frequency and calculate the cumulative percent defects for each: Reason Inadequate parts Test equipment down Delay in inspection No schematic available Awaiting engineering decision Lack of personnel available Frequency 40 22 15 11 10 3 Cum. Frequency 40 62 77 88 98 101 Cum. Percent 40/101 = 39.6% 62/101 = 61.4% 77/101 = 76.2% 88/101 = 87.1% 98/101 = 97.0% 101/101 = 100% (4 marks) We can then prepare a chart to aid in our analysis: Problems Lack of personnel No schematic available Awaiting engineering decision Delay in inspection # Defects Cum. % Test equipment down 100 90 80 70 60 50 40 30 20 10 0 Inadequate parts Number of defects Pareto Analysis (4 marks) We can conclude that most of the delay is the result of inadequate parts, and that this is the problem we should concentrate on solving first. (2 marks) S6.5 Autopitch devices are made for both major- and minor-league teams to help them improve their batting averages. When set at the standard position, Autopitch can throw hardballs toward a batter at an average speed of 60 mph. To monitor these devices and to maintain the highest quality, Autopitch executives take samples of 10 Autopitch devices at a time. The average range is 3 mph. Using this information, construct control limits for X-bar and R charts. We are given the following in the question: n = 10, desired X = 60, desired R = 3. We then look up the following values from table S6.1: A2 = 0.308, D4 = 1.777, D3 = 0.233. (2 marks) We then substitute into the formulae for upper and lower control limits: UCL X X A 2 R 60 0.308 3 60.924 (2 marks) LCL X X - A 2 R 60 0.308 3 59.076 (2 marks) UCL R D 4 R 1.777 3 5.331 (2 marks) LCL R D3 R 0.223 3 0.669 (2 marks) S6.11 Your supervisor, Lisa Lehrmann, has asked that you report on the output of a machine on the factory floor. This machine is supposed to be producing optical lenses with a mean weight of 50 grams and a range of 3.5 grams. The following table contains the data for a sample size of n = 6 taken during the past 3 hours: Sample Number 1 2 3 4 5 6 7 8 9 10 Sample Average 55 47 49 50 52 57 55 48 51 56 Sample Range 3 1 5 3 2 6 3 2 2 3 What are the X- and R-chart control limits when the machine is working properly? What seems to be happening? (Hint: Graph the data points. Run charts may be helpful.) We are given the following in the question: n = 6, desired X = 50, desired R = 3.5. We then look up the following values from table S6.1: A2 = 0.483, D4 = 0, D3 = 2.004. (2 marks) We then substitute into the formulae for upper and lower control limits: UCL X X A 2 R 50 0.483 3.5 51.69 LCL X X - A 2 R 50 0.483 3.5 48.31 UCL R D 4 R 2.004 3.5 7.014 LCL R D3 R 0 3.5 0 (2 marks) We can then prepare control charts, on which we plot the data from our samples: X-Bar Chart 58 56 54 UCL 52 50 Sample LCL 48 46 1 2 3 4 5 6 7 8 9 10 (2 marks) R Chart 6 UCL 4 Sample LCL 2 0 1 2 3 4 5 6 7 8 9 10 (2 marks) R values are within control limits. X-bar values are mostly outside the control limits, fluctuating above and below them. The process is out of control, likely due to an assignmable variation. Immediate action is required to find and correct the problem with the machine. (2 marks)