abstract

advertisement

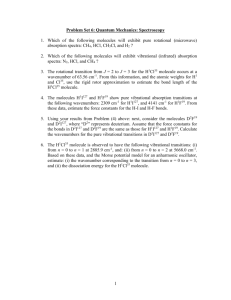

CHEMICAL MODIFICATION OF PVC INTO POLYMER-SUPPORTED OXAZOLINONES AND TRIAZOLES Magdy Y. Abdelaal* and Tariq R. Sobahi Chemistry Department, Faculty of Science, King Abdulaziz University, P.O. Box 80203, Jeddah 21589, Saudi Arabia ABSTRACT PVC (P1) was converted into polymer-supported oxazolinone and triazole derivatives after sequential chemical assembly of the reactive groups onto PVC. Firstly, poly(vinyl chloride-co-vinylaminoaniline) (P2) was prepared by reacting of PVC with p-phenylenediamine. The primary aromatic amino group in P2 was diazotized and reacted with hippuric acid to form the supported oxazolinone derivative (P3) which could be converted into supported triazole derivatives (P4) - (P6) on further interaction with substituted anilines. The involved ring opening and preferred cyclization reactions have been clearly addressed based on spectroscopic and elemental analyses of the products. Also the ability for metal chelation has been roughly tested through the interaction with Cu(II) ions. Keywords: Functional polymers, PVC, oxazolinone, chemical modification, triazole 1. INTRODUCTION Functionalization of polymers has widespread applications as the obtained functionalized polymers acquire the reactivity of the introduced functionality while keeping the main features of the base polymeric matrix [1 - 5]. Hence, many functionalized polymers have been prepared through the reaction of a base polymer with different chemically reactive species such as aldehydes [6, 7], phenols [8] and ketones [9]. Functionalization can also be achieved through physical blending of some organic compounds such as phenolic compounds [10]. Some heterocyclic compounds showed stabilizing efficiency for rubber mixes [11] and their ability for metal chelation is expected as well. Considering the problems in case of physical blending which leading the additives to bloom to the surface of the blend, the chemical blending or functionalization would be beneficial in comparison. Oxazolinones and triazoles are known as common classes of organic compounds and a lot of work have been performed to synthesize different 1,2,4-triazoles either through solution- or solid- phase synthesis strategy. However, a little work has been established in the light of supporting them onto polymer matrices [12 - 17]. The supported organic compounds in the current work have * Permanent Address of Correspondence: Chemistry Department, Faculty of Science, Mansoura University, ET-35516 Mansoura, Egypt; e-mail: magdyabdelaal@yahoo.com been firstly synthesized in the last decade by our group and since that time there is no bulk work has been devoted [11]. The present work deals with chemical modification of (P1) into polymer-supported oxazolinone and triazole derivatives through sequential chemical assembly of the reactive species onto (P1) matrix. Characterization of the obtained modified polymers as well as estimation of the reaction efficiency has been achieved and the possible ability for metal chelation has been also roughly tested through the interaction with Cu(II) ions. 2. EXPERIMENTAL All chemicals were purchased from Aldrich Co., USA unless otherwise mentioned and used without further purification. The modification reactions are represented in Scheme 1. 2.1. Conversion of (P1) into poly(vinyl chloride-co-vinylaminoaniline) (P2): (P1) has been converted into poly(vinyl chloride-co-vinylaminoaniline) (P2) through chemical modification of (P1) with p-phenylenediamine (1). This could be achieved parallel to the method reported before [11]. Elemental and FT-IR spectroscopic analyses have concluded the formation of the above mentioned copolymer (P2) with 70% conversion. The reaction conversion has been calculated from the elemental analysis on the basis of mole fraction concept [18]. 2.2. Conversion of PVC copolymer P2 into oxazolinone-supported polymer (P3): A cold suspension of finely powdered P2 (16.1g, 0.1 mole Ar-NH2 group) in 100 ml of 0.5 M HCl was diazotized with sodium nitrite (35g, 0.5 mole). The reaction mixture was coupled with hippuric acid (2) (22g, 0.12 mole) in 70 ml acetic anhydride containing 3g of freshly fused sodium acetate. After stirring the suspension for 1h while the temperature was kept at 0-5C, the reaction mixture was then filtered off and washed successively with water, ethanol, acetone and finally with ether. The yellowish green product (P3) was dried under vacuum at 40C to constant weight and then subjected for elemental and FT-IR spectroscopic analyses. 2.3. Conversion of (P3) into supported-polymers triazole (P4) - (P6): A mixture of (P3) (19g, 0.1 mole of the oxazolinone residue) and the investigated substituted aromatic amines (1), (3) and (4) (0.12 mole) was soaked for 12h in 70 ml glacial acetic acid and refluxed with stirring for further 8h. The reaction mixture was left overnight to stand at room temperature. The modified polymeric product was filtered off and washed thoroughly with water, acetone and finally with ether. The reaction products (P4) - (P6) were dried under vacuum at 40C to constant weight and then subjected for elemental and FT-IR spectroscopic analyses. 2.4. Loading of the dentate polymer (P2) - (P6) with Cu(II) ions: To about 0.5g of finely powdered modified PVC samples (P2) - (P6), solution of copper acetate (50ml, 0.1M) was added and stirred for 12h at room temperature. The mixture was filtered off and washed thoroughly with distilled water and the metal-loaded modified (P1) samples were separated off. The metal uptake by the modified PVC samples was determined through back determination of the excess Cu(II) in the filtrate and the raw data are listed in Table 1. The metal-loaded samples (P2M) - (P6M) were subjected to FT-IR spectroscopic analysis. Characterization results for all the modified (P1) samples are summarized in Table 1 for the elemental analysis, reaction conversion % and the overall reaction yield % and in Table 2 for FT-IR spectroscopic analysis. 3. RESULTS AND DISCUSSION The chemical modification of polyvinyl chloride (P1) is of great importance as it can be utilized in many application directions. In the present work, (P1) has been modified into polymer-supported oxazolinone and triazole derivatives through sequential chemical assembly of the reactive species onto (P1) matrix. 3.1. Characterization of poly(vinyl chloride-co-vinylaminoaniline) (P2) Scheme 1 represents the overall reaction sequence. Accordingly, (P1) was converted into poly(vinyl chloride-co-vinylaminoaniline) (P2) through the reaction with pphenylenediamine (1) parallel to the previously reported method [11] and the formation of the copolymer (P2) with 70% conversion have been concluded from elemental and FT-IR spectroscopic analyses. (P2) showed absorption at 2850 cm-1 corresponding to CH-N bonding formed by alkylation of (1) with (P1). The unreacted NH2 groups and the obtained NH bonds in (P2) are responsible for the absorption shown at 3480 cm-1 and 3350 cm-1, respectively. Also, insertion of the aniline residues was confirmed by the absorption at 1590 cm-1 corresponding to C=C aromatic in (P2). Comparison of FT-IR spectrum of (P2) with that of (P1) clearly proves such modification of (P1) as it showed absorption bands only at 705 cm-1 corresponding to C-Cl bond in addition to the absorption at 1675 cm-1 for C=C bonds that are mostly occurred in (P10) or arise during the chemical reactions and thermal treatment as well (see Table 2). On the other hand, elemental analysis was used also to prove the achievement of the reaction as well as to estimate the reaction yield based on the mole fraction concept where the carbon content increased from 38.38% to 69.32% and decreased from 56.8% to 9.39% for chlorine while nitrogen was appeared in 17.44% content. These data are corresponding to 70% for both the conversion % and the overall reaction yield (see Table 1). Scheme 1 3.2. Characterization of oxazolinone-supported polymer (P3) The primary aromatic amino groups in (P2) were diazotized and reacted with hippuric acid (2) to form the supported oxazolinone derivative (P3) as a yellowish green product. During the reaction of diazotized (P2) with hippuric acid (2) the obtained product undergoes azo - hydrazo tautomerism resulting in formation of (P7a&b) or reorientation in such a way that hydroxyimino group faces hydrazo NH group (P7c). The intramolecular OH/NH interaction in the reoriented hydroxyiminohydrazo form (P7c) may result in formation of 3-carboxy-1,2,4-triazolyl derivative (P8) which has been excluded hence there is no C=O absorption of free carboxylic group in the FT-IR spectrum. On the other hand, absorption at 3320 cm-1 and at 1050 cm-1 for NH and C-O-C, respectively, were observed confirming the formation of 5-oxazolinone derivative (P3a) or its conformer (P3c). Moreover, absorption at 3500 cm-1 and 1565 cm-1 related to OH and N=N groups justifies the formation of the tautomer 5-oxazolol derivative (P3b). Scheme 2 represents the possible mechanism for the reaction of the diazotized (P2) with (2) to form the polymersupported oxazolinone functionality. Scheme 2 3.3. Characterization of polymers -supported triazole (P4) and (P5): After preparation and characterization of the polymer-supported oxazolinone (P3), the obtained product has been further reacted with different aniline derivatives (1) and (3). Under the reaction conditions, the primary aromatic amino group of (1) and (3) may attack the intramolecular ester functionality in the polymer-supported oxazolinone (P3) resulting in the formation of the corresponding polymer-supported 1,2,4-triazolyl-3-carboxanilides (P4) and (P5) as represented in Scheme 3. Scheme 3 This reaction may undergo simultaneous ring opening amidation of the oxazolinone ring accompanied by regeneration of two conformers of hydroxyimine functionality (P9a&P10a) and (P9b&P10b). Both conformers may undergo condensation cyclization resulting in formation of polymer-supported triazolyl tautomers (P4a&P5a) and (P4b&P5b). Characterization of the obtained products (P4) and (P5) proved their chemical structure either with the aid of FT-IR spectroscopic analysis or with elemental analysis. Both (P4) and (P5) showed approximately similar absorption at 3350 cm-1 (NH), 1670 cm-1 (CONH), 1620 cm-1 (C=N) and 3500 cm-1 (OH) in addition to the absorption at 1590 cm-1 for C=C aromatic. (P4) showed further absorption at 3480 cm-1 corresponding to p-NH2 functionality. Occurrence of hydroxyl group absorption in (P4) in addition to the amide functionality concludes the presence of such amide functionality in the two tautomeric forms (P4a) and (P4b) as represented in Scheme 4. This holds also true for the obtained product (P5). Elemental analysis data of (P4) (C; 66.11%, H; 5.12%, N; 16.66 & Cl; 4.78) and (P5) (C; 66.94%, H; 4.88%, N; 19.06 & Cl; 4.88) concluded that (P4) was obtained in 78% conversion and 35% overall reaction yield while (P5) was obtained in 71% conversion and 32% overall reaction yield (see Table 1). There is another possible way for (P3) to react either with (1) or with (3) through the intramolecular dehydration of the conformer (P9a) and (P10a). This would lead to form the corresponding tautomers (P11a-d) and (P12a-d). Such tautomers are containing in case of their formation - imidazolone hydrazo- (P11a,d) and (P12a,d) or imidazololazo(P11b,c) and (P12b,c) functionalities. Also, they would be free from acyclic amide groups. The obtained products showed absorption at 1670 cm-1 and 3500 cm-1 corresponding to CONH and OH groups, respectively while the absorption in the range of 1560 - 1570 cm-1 was absent. This confirms the formation of the above described (P4a&b) and (P5a&b) and excludes the formation of (P11a-d) and (P12a-d) tautomers. Scheme 4 3.4. Characterization of polymers-supported 2-benzimidazolyl-1,2,4-triazole (P6): On the other hand, by using (4) instead of (1) or (3) the ortho amino group in the corresponding polymer-supported 1,2,4-triazolylcarboxanilide derivative (P14a,b) can undergo further dehydration to produce the corresponding polymer-supported 2benzimidazolyl-1,2,4-triazolyl derivative (P6) as suggested in Scheme 5. The suggested mechanism for the concerned reaction is parallel to that mentioned above for the reaction of (P3) with (1) and (3). The possibility of (P14) to be occur in two tautomers (P14a) and (P14b) facilitates the dehydration reaction of the tautomer (P14b) resulting in the formation of the obtained polymer-supported 2-benzimidazolyltriazolyl derivative (P6). FT-IR analysis of P6 showed absorption at 3300 cm-1 and 1624 cm-1 corresponding to NH and C=N functionalities whereas absorption of either carbonyl or NH2 group is absent (see Table 2). This confirms the intramolecular amidation of the ortho amino group in the corresponding triazole derivative (P14) during the reaction of (P3) with (4) resulting in formation of the corresponding polymer-supported 2-benzimidazolyltriazolyl derivative (P6) as suggested before. Scheme 5 shows two possible inter-convertible forms for (P6) through either tautomerization or free rotation around the bond linking the 2-benzimidazolyl and the 1,2,4triazolyl moieties in (P6). Also, elemental analysis (C; 68.68, H; 4.92, N; 19.48 & Cl; 5.08) confirmed the formation of (P6) in 67% conversion and 30% overall reaction yield as shown in Table 1. Scheme 5 3.5. Application of (P2) - (P6) as metal chelating matrix for Cu(II) ions: The obtained modified PVC samples (P2) - (P6) were treated with an aqueous solution of copper acetate to check roughly their ability to form chelates with Cu(II) ions. The metal uptake by the modified PVC samples was determined through back determination of the excess Cu(II) ions in the filtrate while the metal-loaded samples (P2M) - (P6M) were subjected to FT-IR spectroscopic analysis (see Table 2). The raw data for metal uptake by these polymers are listed in Table 1. FT-IR characterization of the metal-loaded samples (P2) - (P6) proved the metal chelation of the above mentioned polymeric samples with Cu(II) ions. The concerned absorption peaks are shifted after treatment with the metal ion solution as shown in Table 1. Scheme 6 represents the different structural forms of the investigated samples (P3) - (P6) and the more favorable forms for chelation have been framed. (P2) is not included in Scheme 6 because it has only one possibility for chelation as it is a monodentate matrix. Scheme 6 REFERENCES [1] Gnanou, Y., J.M.S.-Rev. Macromol. Chem. Phys., C36(1), 77 (1996). [2] Lassalle, V.L.; Failla, M.D.; Valles, E.M. and Martin-Martinez, J.M., J. Adhes. Sci. Technol., 18(15-16), 1849 (2004). [3] Ilia, G.; Popa, A.; Iliescu, S.; Dehelean, G.; Macarie, L. and Plesu, N., Mol. Cryst. Liq. Cryst., 416, 175 (2004). [4] Izaoumen, N.; Bouchta, D.; Zejli, H.; El Kaoutit, M.; Stalcup, A.M. and Temsamani, K.R., Talanta, 66(1), 111 (2005). [5] Mathiyarasu, J.; Senthilkumar, S.; Phani, K.L.N. and Yegnaraman, V., J. Appl. Electrochem., 35(5), 513 (2005). [6] Sarhan, A.A.; Abdelaal, M.Y.; Ali, M.M. and Abdel-Latiff, E.H., Polymer 40, 233 (1998). [7] Sarhan, A.A.; El-Shehawy, A.A. and Abdelaal, M.Y., React. Funct. Polym. 50(2), 139 (2002). [8] Abdelaal, M.Y.; Kenawy, I.M.M. and Hafez, M.A.H., J. Appl. Polym. Sci. 77(14), 3044 (2000). [9] Sarhan, A.A.; Afsah, E.M.; Abdelaal, M.Y. and Ibrahim, M.R., React. Funct. Polym. 32, 231 (1997). [10] Sobahi, T.R., Mans. J. Chem. 32(2), 73 (2005). [11] Abdel-Bary, E.M.; Moawad, E.B.; Helaly, F.M.; Abdelaal, M.Y. and Rashed, W.F., Polym. Degrad. Stab. 57, 283 (1997). [12] Ahna, J.H. and Sherrington, D.C., Chem. Commun., , 5, 643 (1996). [13] Katritzky, A.R. and Qi, M., J. Org. Chem., 62, 4116 (1997). [14] Katritzky, A.R.; Qi, M.; Feng, D. and Nichols, D.A., J. Org. Chem., 62, 4121 (1997). [15] Katritzky, A.R.; Lan, X.; Yang, J.Z. and Denisko, O.V., Chem. Rev., 98, 409 (1998). [16] Katritzky, A.R.; Qi, M.; Feng, D.; Zhang, G.; Griffith, M.C. and Watson, K., Org. Lett. 1(8), 1189 (1999). [17] Katritzky, A.R.; Pastor, A.; Voronkov, M. and Tymoshenko, D., J. Comb. Chem. 3, 167 (2001). [18] Abdelaal, M.Y. and Elmorsy, S.S., Angew. Makromol. Chem. 233, 15 (1995). CAPTIONS Scheme 1: Modification of (P1) into polymer-supported oxazolinone and triazole (P2) - (P6) Scheme 2: Formation of the polymer-supported oxazolinone derivative (P3) Scheme 3: Reaction of (P3) with (1) and (3) Scheme 4: Outlines for the possible mechanism of the reaction of (P3) with (1) and (3) Scheme 5: Suggested mechanism for the reaction of (P3) with (4) Scheme 6: Metal chelates of the obtained polymeric samples (P3) - (P6) Table 1: Elemental analysis data and metal uptake for the chemically modified (P1) Table 2: FT-IR spectroscopic data for the chemically modified (P1) NH2 H2N CH2 CH Cl (1) i. NaNO 2 /HCl ii. Hippuric acid (2) P n P NH NH2 (P1) N (P2) O NH 2 N O Ph R P P P N Ph N N N O HN N H N = CH 2 CH NH Ph N N (P6) (P3) R = p-NH 2 (1) = p-OH (3) R = o-NH 2 (4) R (P4) & (P5) Scheme 1 x = 0.30 = 0.45 = 0.35 = 0.32 = 0.30 ( P2) ( P3) ( P4) ( P5) ( P6) R = p-NH 2 ( 1, P4) = p-OH ( 3, P5) = o-NH 2 ( 4) x i. NaNO 2 /HCl ii. Hippuric acid (2) P P P N NH2 NH N (P2) N H O O N HO P O O N (P7a) N Ph (P7c) (P7b) OH/CO 2 H inte raction P NH O NH N O O O N Ph (P3a) Scheme 2 N O OH O (P3b) Ph N Ph (P3c) P N H N O Ph P N N N OH/NH interaction P N Ph HO HO HO Ph NH OH N (P8) P P P NH2 NH N O N R (1), (3) N Ph N N H O N N O N H O Ph N N Ph (P3) R = NH 2 (1), (P4) R = OH (3), (P5) R R (P4a) & (P5a) (P4b) & (P5b) Scheme 3 P P NH2 NH NH N N NH HO R O (1)&(3) (P3) O N N Ph N O + O P NH OH N NH Ph R R (P9a) & (P10a) (P9b) & (P10b) - H2O - H2O P P N P N NH N HO N N N N Ph O N H N O Ph N N Ph R R (P4a) & (P5a) (P11b) & (P12b) R (P11a) & (P12a) P P N NH N N Ph P N N OH N N Ph O N R (P11d) & (P12d) R = NH2 (1), (P4), (P9), (P11) N HO N R (P11c) & (P12c) Ph N R (P4b) & (P5b) R = OH (3), (P5), (P10), (P12) Scheme 4 Ph P P NH2 NH N NH N NH2 + O H2N N O O H2N NH HO (P3) O Ph N NH Ph (P13a) (P13b) - H2O P NH OH N N (4) Ph P - H2O P N N N HO Ph N N NH O N N H2N N P H2N Ph N H N O N H2N P N Ph (P15b) (P14a) P - H2O N HO H2N (P15a) N Ph N N N H - H2O N N P N (P14b) Ph N Ph N (P16a) H N N P N P N P Ph N N N N H N H N N Ph (P6a) N H N N N N N N Ph (P6b) (P16b) (P16c) Scheme 5 P N N P P N + N O N O Ph N + Cu N Ph N + N (P3Mc) P N N O Ph (P3Mb) P Ph R (P4Ma)&(P5Ma) + N Cu P N N Ph N N R (P4Mb)&(P5Mb) Scheme 6 Ph N N O Cu O O Ph P Cu N O (P3Ma) N N Cu Cu O + N + N N N N N (P6Ma) (P6Mb) + Cu Table 1: Elemental analysis data and metal uptake for the chemically modified (P1) Sample P1 P2 P3 P4 P5 P6 C (%) H (%) 38.38 69.32 65.18 66.11 66.94 68.68 4.78 7.08 4.45 5.12 4.88 4.92 Elemental Analysis Data Conversion N (%) Cl (%) (%) 56.80 17.44 9.39 70 17.07 5.69 64 19.06 4.78 78 16.66 4.88 71 19.48 5.08 67 Overall Yield (%) 70 45 35 32 30 Metal Uptake (mg/g) 285 150 200 205 105 Table 2: FT-IR spectroscopic data for the chemically modified (P1) Sample P1 P2 P3 P4 P5 P6 705 1675 2850 3480 3350 1590 3320 1621 1050 3500 1590 3350 1670 1620 3480 3500 1590 3350 1670 1622 3500 1590 3300 1624 Metal-Unloaded Polymer Description -C-Cl -C=C-CH-N-NH2 -NH C=C aromatic -NH -C=N-C-O-C-OH C=C aromatic -NH -CONH-C=N-NH2 -OH C=C aromatic -NH-CONH-C=N-OH C=C aromatic -NH-C=Nabsence of C=O, NH2 (cm-1) 705 1673 3460 Metal-Loaded Polymer Description -C-Cl -C=CShift of NH2 absorption peak due to possible chelating (cm-1) 1572 1675 1658 -N=N-C=C-C=C-O-.+Metal 1612 3460 -N=C-O-.+Metal Shift for NH2 absorption peak 1613 3482 -N=C-O-.+Metal Ph-O-.+Metal 3289 Shift of NH- absorption peak due to possible chelating