HYDROGEN ISOTOPES PURIFICATION SISTEM

PROCEEDINGS of the FIFTH INTERNATIONAL CONFERENCE "CRYOGENICS '98", Praha,

Czech Republic, 1998.

AP5

HYDROGEN ISOTOPES PURIFICATION SISTEM

AND DEVELOPMENT OF THE TECHNOLOGY OF HIGH PURIFICATION

OF HYDROGEN ISOTOPES BY CRYOADSORPTION METHOD

I.A. Alekseev, S.D. Bondarenko, V.D. Trenin

Petersburg Nuclear Physics Institute,

188350 Gatchina, Leningrad district, Russia

ABSTRACT

The system of compression, purification and storage of the hydrogen isotope mixtures (CPS system) is intended for the supply of cryogenic distillation column of the hydrogen isotope separation assembly and the reactor WWR-M cold neutron source. Cryoadsorption method is used for the purification of hydrogen isotopes from nitrogen and oxygen impurities up to level of 10 -6 -10 -7 % vol.

A brief overview of CPS system principles is presented, followed by a review of development of the technology of high purification of hydrogen isotopes by cryoadsorption method at CPS system.

The influence of pressure, of initial gas purity, of feed gas flow rate, of adsorbent preliminary preparation upon efficiency of hydrogen adsorption purification process was studied. The optimum conditions of process are determined. The techniques of hydrogen isotopes adsorption purification from nitrogen and oxygen microimpurities on SCN-2K and SCT-4 activated carbons was developed.

Concentration of impurities is reduced up to 10 -7 % vol.

I. INTRODUCTION

Hydrogen high purification from traces of oxygen, nitrogen and other impurities is exceptionally important for cryogenic distillation column of hydrogen isotope separation. The less content of impurity in liquefied hydrogen, the less probability of emergency and a longer running cycle of installation. Oxygen and nitrogen recovery from hydrogen isotope flow up to level of 10

-6

% vol. is needed at detritiation plant of

PIK reactor, which is constructing in Gatchina, Russia, for it normal operation.

The system of compression, purification and storage of the hydrogen isotope mixtures (CPS system) of Petersburg Nuclear Physics Institute is intended for the supply of cryogenic distillation column of hydrogen isotopes separation assembly and reactor WWR-M cold neutron source. In this industrial system we have studied the influence of different factors to efficiency of hydrogen adsorption purification process to improve purification. The paper presents the experimental data and determined optimum conditions of purification process.

II. EXPERIMENTAL

The system of compression, purification and storage of the hydrogen isotope mixtures (CPS system) consists of a hydrogen membrane compressor, purification unit, storage unit as well as the adsorption cryopump for hydrogen isotope pumping to residual pressure 10 Pa without using of mechanical means 1 . Storage unit consists of bottles, recipient and receivers for the storage of 600 m

3

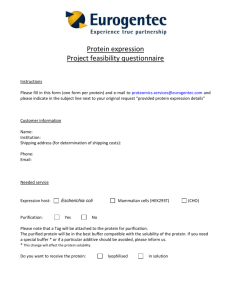

(STP) of hydrogen isotope mixture. Figure 1 shows the schematic flow diagram of purification unit of CPS system.

212

The feed gas was supplied from gasholder 1 to the purification unit by a membrane compressor 2. The membrane compressor type 4MK 20/220 provided the feed gas flow up to 20 STP m

3

/hour and pressure up to 20 MPa. Purified mixture was

Fig. 1 The schematic flow diagram of purification unit of CPS system.

1- gasholder; 2- membrane compressor; 3- molecular sieve bed; 4- activated carbon bed; 5-heat exchanger; 6- hydrogen manifold; 7-vacuum pump; 8-storage unit. supplied to storage unit or cryogenic distillation column. Inlet and outlet concentrations of N

2 and O

2

in hydrogen were measured on-line by gas chromatograph.

Two sets of 4A molecular sieve bed 3 and activated carbon bed 4 are installed in purification unit. When one set is under operation, another set is regenerated. Hydrogen isotope mixture is dried to a dew point of -70

C in molecular sieve bed at ambient temperature. Nitrogen and other impurities were removed in activated carbon bed with diameter 90 mm and height 950 mm. Two types of activated carbon have been investigated. They are activated carbon type SCT–4 with total weight 2600 g and activated carbon type SCN–2K

2

with total weight 2013 g. Activated carbon bed was placed in stainless still tube and was cooled by liquid nitrogen. The temperature of the activated carbon bed was measured with platinum resistance thermometer. The pressure controller set the pressure at the purification unit outlet in range of 1.3 MPa – 15 MPa.

Adsorbents were regenerated by heating with hot nitrogen and pumping up to 0.1 Pa during of 2 to12 hours, activated carbon bed being warmed to 170

C.

III. RESULTS AND DISCUSSION

The influence of pressure, of initial gas purity, of feed gas flow rate, of adsorbent preliminary preparation upon efficiency of a hydrogen adsorption purification process was studied.

It is found that the initial content of impurities of N

2 and O

2 over the range 10

-4

–

1 vol. % is not affected by to the outlet concentration of the impurities.

At the experiments the feed gas flow rate is varied of 0.2 m/sec to 0.57 m/sec for

SCT-4 activated carbon and of 0.2 m/sec to 6.2 m/sec for SCN-2K activated carbon bed.

Test shows that gas flow rate has no significant effect on the gas purification.

213

The gas pressure is varied from 1.3 MPa to 15 MPa. It may be noted that the pressure of purification has appreciable influence at production of hydrogen with the contents of impurity less than 10

-6

% vol. In this case optimum pressure is over the range 1.3-2.0 MPa both for SCT-4 activated carbon and for SCN-2K activated carbon.

When the given quantity of impurity content in effluent hydrogen is above 10 -5 % vol., the pressure is not influence on purification process.

The determining influence of quality of adsorbent regeneration and cooling mode at production of high purity gases has been noted 3, 4 . This influence can be explained as influence of residual adsorption and initial distribution of adsorbat along the adsorption bed during non-steady adsorption process. The residual adsorption depends on quality of adsorbent regeneration. The initial distribution of adsorbat along the adsorption bed during non-steady adsorption process depends on purity of gas filling adsorption bed.

The next investigation was made to determine of influence of cooling mode: cooling of activated carbon bed by immersing in liquid nitrogen bath; cooling of activated carbon bed by direct cold gas flow; cooling of activated carbon bed by return cold gas flow. Pressure of regeneration, purity of gas filling adsorption bed, rate of adsorption bed cooling was varied at the experiments.

When immersing in liquid nitrogen bath was applied for cooling of activated carbon bed; the purity of effluent gas was not better than 10

-5

% vol. of N

2 and O

2

. With activated carbon bed being cooled by cold gas flow we could produce of hydrogen isotope mixture with impurities content at level of 10 -6 - 10 -7 % vol. In this case formation of an adsorption front and distribution of adsorbed impurity at a nonstationary stage of adsorption occurs only on some part of adsorption bed, and other volume of adsorption bed is blown by pure gas. As advance of temperature front to the subsequent layers of adsorbent the contents of initially adsorbed impurity is reduced and, accordingly, the purity of equilibrium outgoing gas raises. But the good result was achieved only at the certain rate of cooling of an adsorption bed.

It is necessary to emphasize that using of SCN-2K activated carbon bed allows to produce gas with half impurity content in comparison with SCT-4 activated carbon bed the other conditions being equal.

As a result of our studies some practical conclusions can be made. At the industrial system we can purify of hydrogen isotope mixture up to level of impurities content of 10

-6

-10

-7

% vol. Activated carbon SCN-2K is preferable of use at the hydrogen isotope purification. Cooling of activated carbon bed by the direct cold gas flow at the certain rate of cooling and purification at optimal pressure allows to produce the high purification hydrogen isotope mixture.

REFERENCES

1.

V.D.Trenin, I.A.Alekseev, I.A.Baranov, S.D.Bondarenko, S.P.Karpov, K.A.Konoplev,

T.V.Vasyanina, O.A.Fedorchenko, V.S.Kortikov, A.S.Bronstein, A.K.Golovchenko. Full-scale experimental assembly for Hydrogen isotopes separation studies by cryogenic distillation. Assembly and Results of the studies// FUSION TECHNOLOGY, Vol.28. No.3. P.761-766. (1995).

2.

Alekseev I.A., Bondarenko S.D., Trenin V.D. The study of gas cryoadsorption on the charcoal SCN-

2K for hydrogen isotopes high purification. 1998. This conference.

3.

Brilliantov N.A. and Fradkov A.B. Soviet Physics – Technical Physics. Vol.2. P.2239. (1957).

4.

Kirillov I.I., Petukhov S.S., Krivonosov L.S. The problem of cryogenic engineering. Balashikha.

NPO “KRIOGENMASH”. 1989. P. 138.

214