22.033 MSR Final Rep..

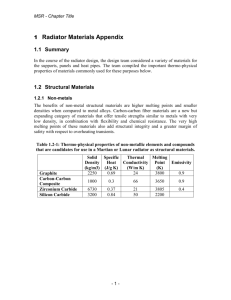

advertisement