Radiator Abstract

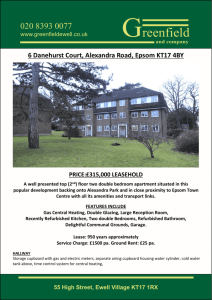

advertisement

Radiator Concept for an MIT Nuclear Power Station for the Moon and Mars David M. Carpenter – MIT Matthew C. Hine – MIT Andrew C. Kadak – MIT Samina Shaikh – MIT Heat rejection in space is more challenging than on Earth as radiation is the only useful mode of heat transfer. The environments of the Moon and Mars offer similarly constrained options for heat rejection because of their extremely sparse atmospheres and lack of accessible water. This investigation details the design of a finned heat pipe radiator intended to operate on both the Moon and Mars, and reject 900 kW of waste heat to the environment. This radiator is designed to be an integral part of a 100 kWe fission reactor intended to function on the Lunar or Martian surface, and operate without maintenance for at least five years. The radiator is composed of 127 potassium heat pipes that run from the reactor power conversion unit and curve into a conical shell above the reactor. A thin fin extends from each heat pipe to form the 39 m2 conical radiating surface, which is angled upwards from the reactor at 52 degrees. This design is only 4.8 m in diameter and 3 m tall, meaning it will fit in currently available launch vehicles in its fully assembled form. In addition, the radiator can be landed in its launch configuration, and does not require any unpacking before becoming operational on a planetary surface. The conical radiator panel and the heat pipe shells are constructed of a Carbon-Carbon composite, which provides good thermal conductivity and emissivity with very low density. The exposed surfaces of all Carbon-Carbon composites are coated with silicon carbide to prevent oxidation. The inside of this cone is supported by a titanium frame, which anchors it to the central reactor assembly. The weight of the heat pipes, frame and panel is only 306 kg, meaning the radiator is not a significant contribution to a surface nuclear the power system’s overall mass. This light and compact design makes the system very attractive for extraterrestrial applications as low mass and small size reduces launch costs and allows more efficient use of payload space. In addition, this design is modular, resistant to single point failures and easily scalable, making it both robust and versatile.