Chapter 11 Section 1

advertisement

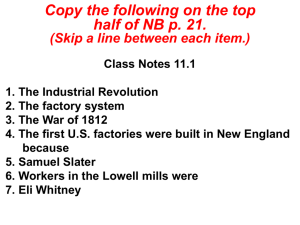

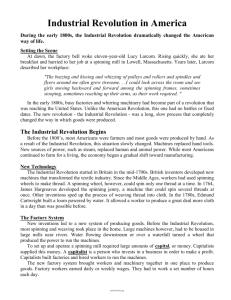

“The Industrial Revolution” * * * * * * * * * * * * Focus Question: How did the new technology of the Industrial Revolution change the way Americans lived? *Early 1700s – most people worked as farmers. Men worked in fields to provide food for family, women helped in fields and made goods like candles and soap. A Revolution in Technology *Industrial Revolution = a change in the 1700s when machines took the place of many hand tools. The power that had been produced by people and horses began to be replaced by flowing water and then by steam engines. *Industrial Revolution began in British clothmaking factories. Machines and Factories *1760s – the spinning jenny speeded up the thread-making process. The jenny allowed a person to spin many strands at once, although the thread was still made by hand. *1764 – Richard Arkwright invented the water frame, a spinning machine powered by running water rather than human energy. *To house the large machines, manufacturers built textiles mills on the banks of rivers. The new mills created a factory system (brings workers and machinery together in one place). *Textile workers now had to go to factories and work specific hours while keeping up with the machines, instead of working at their own pace. *British mill owners recognized the advantages of the water frames and factory system, but the system required a lot of money invested in the buildings and machines. Mill owners asked capitalists (people who invest capital, or money, in a business to earn a profit) for help. Amount of cloth produced from 1765 to 1784 increased by 24 times! Steam Power *Disadvantages of factories on riverbanks: when rivers were dry, machines had no power; factories were far from cities so labor was hard to find in rural areas. *1790 – Arkwright built the first steam-powered textile plant. Factories no longer had to be built by rivers. Young women and children from cities provided cheap labor. *Britain tried to keep their industrial successes secret. Skilled workers were forbidden to leave Britain. No one was allowed to take information about the textile machinery out of Britain. The American Industrial Revolution *1789 – Samuel Slater (apprentice of Arkwright) came to US. He memorized the plans of Arkwright’s machines so he could rebuild them in US and get rich. *Slater joined with a wealthy merchant, Moses Brown. Brown rented a textile mill and Slater reproduced a spinning jenny like Arkwright’s and produced cotton thread at a very fast rate. American Industry Grows *Industrialization in America began in the Northeast with the success of Slater’s mill. This region had merchants who had the capital to build factories and buy raw materials. *American industry grew significantly after the War of 1812 when the US had to make its own goods due to the British blockade. The Lowell Mills *Francis Cabot Lowell had seen the weaving machines in Britain and built an improved version upon returning to the US. *With several capitalists, Lowell opened a mill in Waltham, MA. It brought together spinning thread and weaving in one building. *After Lowell’s death, his partners built a new town with boardinghouses for the workers, a library, and a hospital. They called it Lowell. Lowell Girls *The new factories used young women from nearby farms. After work, “Lowell girls” would attend lectures or visit libraries. Many gained an education and were strictly supervised. The Revolution Takes Hold *Mass production – rapid manufacturing of large numbers of identical objects. *Before 1800s, items were handcrafted by skilled workers. When a part broke, a craftsworker had to create a unique piece to fit the product. *1790s – American Eli Whitney used a system of interchangeable parts (identical pieces that could be assembled quickly by unskilled workers). *Manufacturing became more efficient and the price of goods dropped. As people bought more goods, US industry expanded to satisfy their needs. Factory Life *Lowell mills treated factory workers in a new and kinder way. This was not the norm. Slater employed children in his mill and, as time went on, working conditions got worse. Child Labor *1800s – children worked on family farms. Their labor was needed to help feed the family. Textile mills, coal mines, and steel foundries employed children as young as 7 or 8. They had no chance for education and worked in unsafe conditions. *By 1880 – more than a million children aged 10 to 15 worked for pay. Factory Conditions *Factories were poorly lit and had little fresh air. Many workers were injured from the machines. Workers who lost limbs received no help (like laws today require), but had to rely on the family for support. Business owners provide no payment for disabled workers. *Workdays lasted 12 or 14 hours. By 1844, workers were demanding shorter days but it would not happen for a long time. Review Questions *How did the Industrial Revolution change the way work was performed? Ex. Machines took the place of hand tools. *Why did Samuel Slater have to build his machines from memory? It was against British law to take technology out of England, so he had to memorize the plans for machines. *How was the Lowell factory system different from the European factory system? Instead of obtaining thread from separate spinning mills, Lowell’s brought together spinning and weaving in one building. *How did Eli Whitney’s system of interchangeable parts speed up the manufacturing process? Through mass production, American factories made identical pieces that could be assembled by unskilled workers; skilled workers were not needed.