Travelling Salesman problem

advertisement

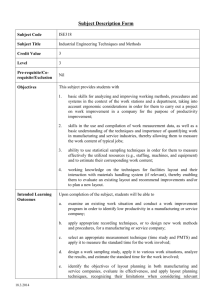

Facility Layout Problems I. History 1.1 Introduction Montreuil's Mixed-Integer Programming Formulation A mixed-integer programming formulation for the facility layout problem was presented by Montreuil in 199098 at a material handling research conference (a slight modification of the model is presented in Tompkins et al., 131 pp. 344-350). The model uses a distance-based objective but is not based on the traditional discrete (QAP) framework. Instead, it utilizes a continuous representation of a layout. The notation and general formulation follow. Note that a specialized case of this model was developed by Heragu and Kusiak orientation are specified a priori. 55 where the departmentlength, width, and 1.2 Type of facility layout problems 1.2.1 Single facility Generally speaking, the multi-floor layout problem is more complicated than its single-floor counterpart since the former involves vertical flow and lifts. 1.2.2 Multi-floor facility layout problem As in most computer-based layout algorithms, in MULTIPLE the layout is represented as a matrix. Each element of the matrix corresponds to a grid square (or grid) of specified area, and the space required by each department is expressed as an integer number of grids. To construct the layout, we propose to use a spacefilling curve which simply visits all the grids on a floor. To ensure that a department is not split, all the grids as-signed to a department must be contiguous, i.e., each grid must be adjacent to another grid that has been assigned to the same department. A spacefilling curve can guarantee that no departments will be split because a separate curve is used for each floor and, within each floor, the curve visits the "neighbors" of a grid before visiting other grids. 1.2.3 Multi-floor and single-floor difference 1. The impact of vertical flow must be considered. Note that vertical travel occurs via access to a life, which we define as any vertical material handling device. Thus, if two departments arc located on different floors, vertical travel will be necessary, and due to the location of a life, the horizontal travel between the two departments may be also increase. 2. The determination of area feasibility. Problem Definition: 2.1 Problem Model: Minimize f ( i,j)F ij (xij xij yij yij ) M(h h v v ) subject to X i xi xi X i i C (1) Y i yi y i Y i i C (2) P i 2( x i x i y i y i ) P i i C (3) x i xi x t i C (4) y i yi y t i C (5) (i,j) F (6) (i,j) F (7) i C (8) i C (9) Ri|j R j|i Ri/j R j/ 3 i (i j ; i, j C) (10) Ri|j ,Ri/j 0 or 1 (i j C) (11) x i x j MRi|j (i j C) (12) y i y j MR j|i (i j C) (13) xi x j xij xij ij yi y j y y ij 0 x i BH h -h 0 y i BH v v - Where fij represents interstation flow between input/output station of cell i and input/output station of cell j. M is a large positive integer. C is the set of cells, F is the set of flows underscore and bar represent lower and upper bounds respectively. Xi and Yi represent position independent length and width dimensions of cell i. Pi represents perimeter of cell i. x i and y i represent lower length and width co-ordinate values for cell i. x i and y i represent upper length and width co-ordinates. xi and yi represent input/output station location co-ordinates of cell i. BH and BV represent facilities envelope upper limit co-ordinate values Ri|j =0 if cell i is imposed to be to the west of (left of) cell j. =1 if the cell above imposition is not enforced. xij , yij , h and v are positive numbers representing positive components of xi-xj, yi-yj, penalty variable for crossing BH and BV respectively xij , yij , h and v are positive numbers representing negative components of xi-xj, yi-yj, penalty variable for crossing BH and BV respectively. II. Applications Application 1 Source: Banerjee, P., Montreuil, B., Moodie, C.,L., Kashyap, R.,L., 1992. A modeling of interactive facilities layout designer reasoning using qualitative patterns. International Journal of Production Research, 30(3), 433-453. Description: The first case is entiled ‘Hypo Manufacturing Company’. The data for the case is shown in Table1. A starting solution for this experiment is the layout show in Fig3. The initial rectilinear inter-station flow travel score for this solution state is 24665. The context setting agent sets context agent sets context 1 and informs the scheduling and governing agents. An aggregate scheduling of the QLA set is performed by the scheduling agent. Application 2 Source: Bozer, Y.,A., Meller, R.,D., Erlebacher, S.,J., 1994. An improvement type layout algorithm for single and multiple oor facilities. Management Sci, 40 (7), 918-932. Description: The problem is based on a 15-department, three-floor facility with six existing (or potential) lifts. The departmental area data are shown in Table 1. (We assume there are no upper bounds imposed on depart-ment areas.) Department 15 (the receiving/ shipping department) is fixed in its current location in the initial layout, which is shown in Figure 5a. Table 1 Area requirement for the multi-floor example problem Department Current Area Minimum Area 1 15 12 2 3 4 5 6 7 8 10 9 7 9 25 25 15 7 6 5 7 22 22 13 9 10 11 12 13 14 15 10 25 10 15 6 9 25 7 22 9 13 4 17 25 Figure 5a Application 3 Source: Y.A., Bozer, R.D., Meller, 1997. A reexamination of the distance-based facility layout problem. International journal of production research, 29, 549-560. Description: The first data set consists of nine departments, with four small, three medium and two large departments of area 9, 16, and 36 units, respectively. The building is 13units long and 12units wide. For the second example, we use a 12-department problem with two large, two medium, and eight small departments of area 16, 4, and 1 units, respectively. The building is 8 units long and 6 units wide. Thus for both examples the total area required is equal to the total area available in the facility. Also, the department sizes were chosen so that square departments are possible and ideal for the QAP-approach (note that departments with area 36 would ideally be diamond shaped; however, the facility area prohibits this choice). Application 4 Source: Tam, K. Y., CHAN, S. K., 1998. Solving facility layout problems with geometric constraints using parallel genetic algorithms: experimentation and findings. International Journal of Production Research, 36(12), 3253-3272. Description: The factors considered in our comparison are (1) parallel GA algorithm; (2)problem size; and (3) number of processors. The first factor includes the four parallel GAs, namely the centralized implementation (CENT), the semi-distrubted parallel GA (SEMI), the distributed parallel model (DIST), and the totally distributed parallel GA (TOTAL). For problem size (factor 2), layouts for 5, 7, 10 and 20 facilities are compared. Since algorithm (factor 1) and number of processors (factor 3) are not independent, the latter is nested in the former in our experiment. III. Reference [1] Banerjee, P., Montreuil, B., Moodie, C.,L., Kashyap, R.,L., 1992. A modeling of interactive [2] [3] [4] [5] facilities layout designer reasoning using qualitative patterns. International Journal of Production Research, 30(3), 433-453. Sherali, H., D., Fraticelli, Barbara M., P., Meller, D., 2003. Enhanced Model Formulations for Optimal Facility Layout. Operations research, 51(4), 629-644. Meller, R.D., Bozer, Y.A., 1996. A new simulated annealing algorithm for facility layout problem. International journal of production research, 34(6), 1675-1692. Meller, R. D., Chen, Sherali, W., H.,D., 2007. Applying the sequence-pair representation to optimal facility layout designs. Operations Research Letters, 35(5), 651-659. Meller, R. D., K. Y. Gau. 1996. The facility layout problem: Recenta nde mergingtr endsa ndp erspectives.J. Manufactur-ing Systems ,15(5), 351-366. [6] Meller, R., D., Narayanan, V., Vance, P.,H., 1999. Optimal facility layout design. Operations esearch letters, 23(3-5), 117-127. [7] Y.A., Bozer, R.D., Meller, 1997. A reexamination of the distance-based facility layout problem. International journal of production research, 29, 549-560.