Electrode diameter for non-structural small attachments before hydro

advertisement

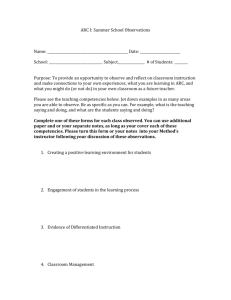

Agenda Item 650-2014 Subject: Pub & Edition: Contact: Electrode diameter for non-structural small attachments before hydro test API 650, 12th Edition (March 2013) Source: Name: Ryan Whitaker Company: Kinder Morgan Inc. Phone: 713-450-0461 E-mail: ryan_whitaker@kindermorgan.com Provide clarification that requirements of 7.2.1.12 a-e shall only apply following hydrostatic testing. Inquiry Revision: 1 Purpose: Allows for utilizing rods other than 1/8” low hydrogen when welding small attachments prior to hydrotesting. Background: Para 7.2.1.12 states that welding of non-structural small attachments to the exterior of the shell before or after hydrostatic testing can be done provided c) The maximum shielded metal arc electrode is limited to 3mm (1/8 in.) diameter and shall be low-hydrogen type. Current 7.2.1.12 Non-structural small attachments such as insulation clips, studs and wording: pins but not insulation support rings or bars may be welded by the arc stud, capacitor discharge or shielded metal arc process to the exterior of the shell including reinforcing plates or PWHT assemblies and roof either before or after hydrostatic testing is performed, but before the tank will be filled with product provided: Impact: a) The attachment locations meet the spacing requirements of 5.8.1.2a. b) The arc stud welding process in limited to 10 mm (3/8 in.) maximum diameter studs or equivalent cross-section. c) The maximum shielded metal arc electrode is limited to 3 mm (1/8 in.) diameter and shall be a low-hydrogen type. d) The attachment welds, except for those made by the capacitor discharge method, shall be inspected per 7.2.3.6. The attachment welds made by the capacitor discharge method shall be visually examined for all types and groups of shell materials. e) All stud welding and capacitor discharge procedures have been qualified in accordance with ASME Section IX. Capacitor discharge procedures do not require procedure qualification provided the power output is 125 watt-sec or less. The shielded metal arc weld procedures shall meet the requirements of Section 9 for qualification for use. Proposal: 7.2.1.12 Non-structural small attachments such as insulation clips, studs and pins but not insulation support rings or bars may be welded by the arc stud, capacitor discharge or shielded metal arc process to the exterior of the shell including reinforcing plates or PWHT assemblies and roof either before or after hydrostatic testing is performed, provided: a) The attachment locations meet the spacing requirements of 5.8.1.2a. b) The arc stud welding process in limited to 10 mm (3/8 in.) maximum diameter studs or equivalent cross-section. c) The maximum shielded metal arc electrode is limited to 3 mm (1/8 in.) diameter and shall be a low-hydrogen type. d) The attachment welds, except for those made by the capacitor discharge method, shall be inspected per 7.2.3.6. The attachment welds made by the capacitor discharge method shall be visually examined for all types and groups of shell materials. e) All stud welding and capacitor discharge procedures have been qualified in accordance with ASME Section IX. Capacitor discharge procedures do not require procedure qualification provided the power output is 125 watt-sec or less. f) The shielded metal arc weld procedures shall meet the requirements of ASME Section 9 IX for qualification for use. 7.2.1.13 If installation of non-structural small attachments is performed following hydrostatic testing, the requirements of 7.2.1.12 shall be performed along with the following requirements: a) The arc stud welding process in limited to 10 mm (3/8 in.) maximum diameter studs or equivalent cross-section. b) The maximum shielded metal arc electrode is limited to 3 mm (1/8 in.) diameter and shall be a low-hydrogen type.

![Sample_hold[1]](http://s2.studylib.net/store/data/005360237_1-66a09447be9ffd6ace4f3f67c2fef5c7-300x300.png)