Set A - WELCOME to National Certification Examination for Energy

advertisement

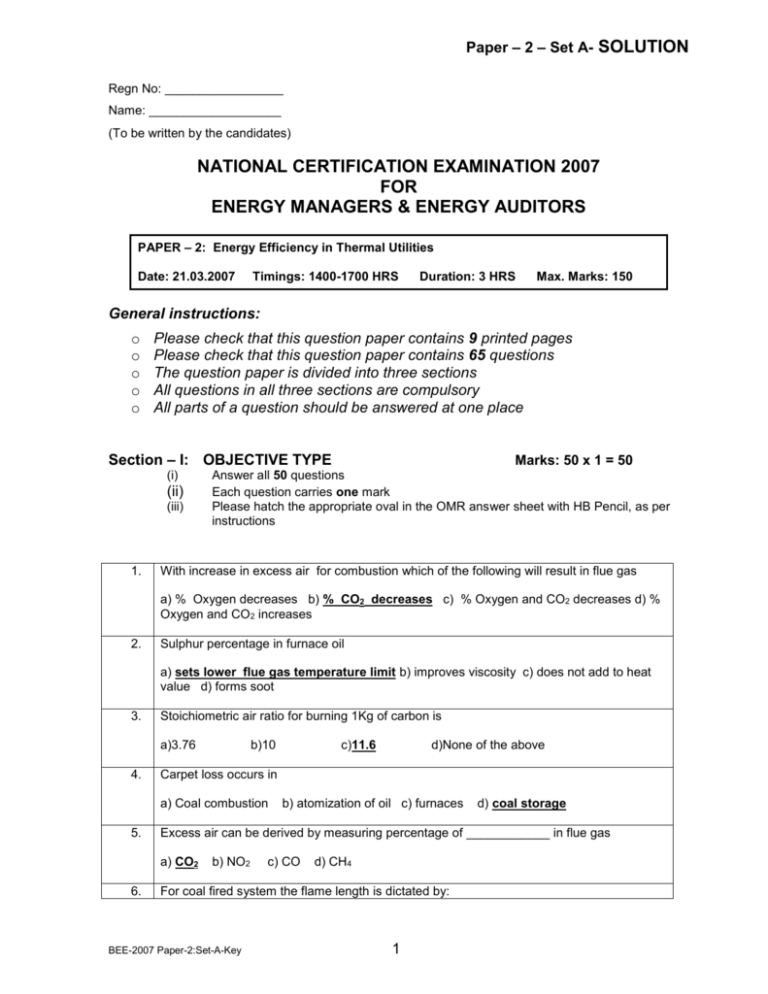

Paper – 2 – Set A- SOLUTION Regn No: _________________ Name: ___________________ (To be written by the candidates) NATIONAL CERTIFICATION EXAMINATION 2007 FOR ENERGY MANAGERS & ENERGY AUDITORS PAPER – 2: Energy Efficiency in Thermal Utilities Date: 21.03.2007 Timings: 1400-1700 HRS Duration: 3 HRS Max. Marks: 150 General instructions: o o o o o Please check that this question paper contains 9 printed pages Please check that this question paper contains 65 questions The question paper is divided into three sections All questions in all three sections are compulsory All parts of a question should be answered at one place Section – I: OBJECTIVE TYPE (i) (ii) (iii) 1. Marks: 50 x 1 = 50 Answer all 50 questions Each question carries one mark Please hatch the appropriate oval in the OMR answer sheet with HB Pencil, as per instructions With increase in excess air for combustion which of the following will result in flue gas a) % Oxygen decreases b) % CO2 decreases c) % Oxygen and CO2 decreases d) % Oxygen and CO2 increases 2. Sulphur percentage in furnace oil a) sets lower flue gas temperature limit b) improves viscosity c) does not add to heat value d) forms soot 3. Stoichiometric air ratio for burning 1Kg of carbon is a)3.76 4. b)10 b) atomization of oil c) furnaces d) coal storage Excess air can be derived by measuring percentage of ____________ in flue gas a) CO2 6. d)None of the above Carpet loss occurs in a) Coal combustion 5. c)11.6 b) NO2 c) CO d) CH4 For coal fired system the flame length is dictated by: BEE-2007 Paper-2:Set-A-Key 1 Paper – 2 – Set A- SOLUTION a)moisture b) volatile matter. c)ash content. d)fixed carbon. 7. Deaeration in boiler removes a) CO2 in flue gas b) O2 in feed water 8. In pure stoichiometric combustion of furnace oil which of the following will be absent in flue gas ? a) nitrogen 9. c) O2 in fuel d) O2 in fluel gas b) carbon dioxide c) oxygen d) sulphur dioxide When pure hydrogen is burned, with theoretical air, the volume percentage of nitrogen in flue gas on dry basis will be a) 100% b) 79% c) 21% d) 0% 10. The factor that influences atomization of fuel oil the most is a) density b) flash point c) pour point d) viscosity 11. In oil firing burners a) primary air is used for creating turbulence and secondary air for completion of combustion b) primary air is used for cooling oil and secondary air for completion of the combustion c) primary air is used for completion of the combustion and secondary air for creating turbulence d) Primary air is used for atomizations of oil and secondary air for completion of the combustion. 12. Which of the following will require minimum excess air for combustion a) fluidized bed boiler b) spreader stoker boiler c) pulverized coal fired boiler d) manually fired boiler 13. “Turndown ratio” for burners is the ratio of a) air to fuel b) maximum fuel input to actual fuel input c) maximum fuel input over minimum fuel input d) maximum air input over minimum air input 14. Boiler Evaporation ratio is the amount of steam generated in kg a) per unit time b) per kg of fuel burnt c) per m2 of boiler surface area d) per kg of makeup water. 15. For equal capacity, the boiler size is the smallest for a) AFBC b) CFBC c) PFBC d) Pulverized coil fired boiler 16. De-aeration of boiler feed water helps in combating a) corrosion. b)TDS c) silica d) hardness 17. For industrial process indirect heating, the best quality of steam is a) dry saturated steam b) superheated steam c) wet steam d) high pressure steam BEE-2007 Paper-2:Set-A-Key 2 Paper – 2 – Set A- SOLUTION 18. Which one of the following cannot be used as fuel for the gas turbine a) naphtha b) LPG c) natural gas d) LSHS 19. The content of solid left in the oven after volatile matter is distilled off (while analysing the composition of coal in a laboratory) is ___. a) only sulphur b)only moisture c)only ash d) mix of fixed carbon and ash 20. Wetting of coal with water in boiler helps in a) increasing the calorific value of the coal b) keeping boiler grate cooled c) increasing the furnace draft velocity d)stopping coal fines to fall through grate and being carried away with furnace draft 21. The percentage radiation loss from a boiler will a) increase with increased loading b) decreases with increased loading independent of loading d) none of the above c) is 22. Concentration of solids in boiler drum is controlled by a)reducing dosage of chemicals b)steam venting c)blowdown d)deaeration 23. Which fuel uses the lowest amount of excess air during combustion process? a) pulverised coal b) bagasse c)fuel oil d) natural gas. 24. Pre-heating of combustion air by 1000C will save about ------% of fuel. a)0.5 b)5 c)7 d)None of the above 25. Increase in feed water temperature by 300C for an oil fired boiler results in a savings of -----% of fuel. a) 1 b) 5 c) 4 d) None of the above. 26. Which data is not required in calculation of thermal efficiency of boiler by indirect method a)blow down quantity b)calorific value of fuel c)excess air level d)flue gas temperature. 27. Moisture in combustion air a) contributes to latent heat loss but not sensible heat loss in flue gas b) does not contribute to latent heat loss but contribute to sensible heat loss in flue gas c) does not contribute to latent heat loss and sensible heat loss in flue gas d) contributes to both the latent heat loss and sensible heat loss in flue gas. 28. Steam should always be generated and utilized at a) same pressure b) lowest pressure and highest pressure respectively c) highest pressure and lowest pressure respectively d) atmospheric pressure 29. Velocity of steam in a pipe depends on a)number of bends b)length of pipe c)specific volume of steam BEE-2007 Paper-2:Set-A-Key 3 d)none of the Paper – 2 – Set A- SOLUTION above. 30. Which of the following is not true of steam ? a) highest specific heat and latent heat b) low heat transfer coefficient c) easy to control and distribute d) cheap and inert 31. At the critical point of steam a) boiling point is 0oC b) sensible heat is zero c) enthalpy of evaporation is zero d) total enthalpy is zero 32. What type of steam is generally used for power generation a) high pressure steam with super heat b) dry saturated low pressure steam c) dry saturated steam with high pressure d) wet steam with very high pressure 33. Air must be removed from steam line as a) It reduces partial pressure of steam and decreases thermal resistance to heat transfer b) It increase partial pressure of steam and decrease thermal resistance to heat transfer c) It increases saturation temperature of steam and increases thermal resistance to heat transfer d) It reduce saturation temperature of steam and increase thermal resistance to heat transfer 34. For flash steam calculation, flash steam quantity available depends upon ___ a) condensate pressure and flash steam pressure b) pressure of steam generated in boiler c) steam enthalpy at atmospheric pressure d) total heat of flash steam 35. A bimetallic strip is used in which of the following traps a) float trap b) thermodynamic c) inverted bucket d) thermostatic 36. Which of the energy saving measures will not be applicable for a heat treatment furnace a) complete combustion with minimum excess air b) waste heat recovery from the flue gases c) optimum capacity utilization d) heat recovery from furnace openings 37. Maximum heat transfer to the stock in a reheating furnace is by a) radiation b) conduction c) convection d) none of these 38. High emissivity coatings are most effective on a)outer surface of furnace b)inner surface of furnace c)furnace charge d)none of the above 39. Pick the wrong statement. The thermal efficiency of a furnace increases by a)reducing surface heat loss b)preheating Combustion air. c) maintaining high levels of excess air d)minimising unburnt losses 40. Major heat loss in an furnace is accounted by a)radiation . BEE-2007 Paper-2:Set-A-Key b)openings. c)sensible heat in exit flue gas d)hydrogen in fuel 4 Paper – 2 – Set A- SOLUTION 41. Ceramic fibre gives the maximum savings when used in a) continuous furnace b) batch furnace c) arc furnace d) induction furnace 42. In determining the optimal economic insulation thickness for a steam pipeline, thickness which of the following factors need not be considered a) annual hours of operation b) calorific value c) pipe material d) cost of fuel 43. Magnesite, chrome-magnesite, dolomite are examples of --------- type of refractory a) acid b) basic c) neutral d) none of the above 44. For same inlet conditions of the steam which of the following will generate the maximum mechanical power a) condensing turbine b) back pressure turbine c) extraction-cum-condensing turbine b) extraction-cum-back pressure turbine 45. Co-generation is also known as a)Re-generation system c)Combined heat and power system b)Brayton system d)Reversible system 46. An axial compressor is used in conjunction with which of the following a) Back pressure steam turbine b) Condensing turbine c) Gas turbine d) none of the above 47. Which is not a property of Ceramic fibre insulation a) low thermal conductivity b) light weight c) high heat storage d) thermal shock resistant 48. Chances of NOx formation are least in a) Chain grate stoker boiler b) Spreader stoker boiler c) Pulverized coal fired boiler d) FBC boilers 49. Quality of waste heat in flue gas refers to a) dust concentration in flue gas corrosive gases in flue gas b) temperature c) moisture in flue gas 50. The heat recovery device in which high conductivity bricks are used storing heat is a) heat pipe b) heat pump c) thermo compressor d) regenerator ----------------------End of Section - I---------------------- BEE-2007 Paper-2:Set-A-Key 5 d) Paper – 2 – Set A- SOLUTION Section – II:SHORT TYPE QUESTIONS (10 questions x 5 marks each ) S.1 (Total 50 marks) Discuss the role of three T’s in efficient combustion process Ans 3 T’s of Combustion The objective of good combustion is to release all of the heat in the fuel. This is accomplished by controlling the "three T's" of combustion which are (1) Temperature high enough to ignite and maintain ignition of the fuel, (2) Turbulence or intimate mixing of the fuel and oxygen, and (3) Time sufficient for complete combustion. For sustained combustion the temperature of fuel/air mixture must be at temperature above ignition temperature. Air contains 21% O2 and 79% N2 only O2 takes part in combustion process. For combustion each fuel molecule must be in contact with at least required number of molecules (theoretical) of O2. This is only possible when fuel and O2 is mixed on molecule to molecule basis. This complete mixing will require turbulence in fuel in gaseous from and air. To ensure that each gaseous molecule meets the O2 molecule, the fuel air mixture must stay for sufficient longer period in region where temperature is more than the ignition temperature (Furnace chamber). S-2 In a natural gas fired boiler the air to fuel ratio is maintained at 10Nm3/Nm3 of gas. An air preheater is installed to preheat combustion air at 30ºC. The flue gas temperature decreases from 230ºC to 170ºC. Estimate the rise in temperature of the ambient air assuming that the specific heat of flue gas and ambient air is equal. Ans. Ratio of volume flow rate flue gas to that of combustion air = 11/10 Va.a.Cpa (Toa-Tia) = Vf.f. Cpf. (Tof-Tif) Ratio of density of flue gas to that of combustion air = Toa = Tia + 273 30 303 273 230 503 Vf . f . (Tof – Tif) = 30 + 11/10 x 303/503 x (230-170) Va . a 70ºC (or) If density correction is ignored Va.Cpa (Toa-Tia) = Vf.Cpf. (Tof-Tif) Toa = Tia + Vf . Va . . (Tof – Tif) = 30 + 11/10 x 303/503 x (230-170) 30 + 11/10 x (230-170) 96ºC S-3 Draw a schematic diagram of a combined cycle power plant BEE-2007 Paper-2:Set-A-Key 6 Paper – 2 – Set A- SOLUTION S-4 • • • • • List five benefits of condensate recovery in a process plant For every 60C rise in the feed water temperature, there will be approximately 1% saving of fuel in the boiler. So financial benefits. Reduction in Water charges Minimising effluent temperature and hence adhering to effluent restrictions Maximises boiler output Better boiler feedwater quality S-5 A boiler generates saturated steam at 15 atmosphere absolute pressure (hg = 666 kcal/kg). If the feedwater temperature is 60ºC (hf = 60 kcal/kg), for evaporation ratio of 6 for a particular fuel (GCV of fuel = 4200 kcal/kg), estimate the boiler efficiency. Ans. = = Q(h g h f ) q GCV x 100 6(666 - 60) x 100 4200 = 86.6% BEE-2007 Paper-2:Set-A-Key 7 Paper – 2 – Set A- SOLUTION S-6 Explain the importance of draft in a reheating furnace High negative pressures leads to air infiltration- affecting air-fuel ratio control, cold metal and non-uniform metal temperatures. problems of High positive Pressure leads to Ex-filtration -Problems of leaping out of flames, overheating of refractories,burning out of ducts etc. Hence the optimum condition is to maintain a slightly positive pressure S.7 A boiler is generating steam at 5500 kgs/hr. The maximum permissible limit of TDS in the boiler is 3500 ppm. If the make up water is 40% at a TDS level of 350 ppm, calculate the blowdown percentage and blow down rate. Ans. Blow down percentage = 350 40 = 4% 3500 Blow down rate = 5500 x 0.04 = 220 kg/hr. S.8 How does a thermocompressor work ? Explain briefly with a sketch In a thermocompressor low pressure steam is converted to medium pressure steam by using high pressure steam. The thermocompressor is a simple equipment with a nozzle where HP steam is accelerated into a high velocity fluid. This entrains the LP steam by momentum transfer and then recompresses in a divergent venturi. . S-9 For a coal containing 5% hydrogen (GCV = 5500 kcal/kg), estimates the percentage of sensible and latent heat loss due to evaporation of water formed due to hydrogen in the fuel, if the flue gas temperature is 180ºC and combustion air temperature is 40ºC. (latent heat of vapours = 584 Kcal/kg, specific heat of vapours = 0.45 kcal/kg/0C) Ans. For 0.05 kg of hydrogen per kg of fuel, water generated is = 9 x 0.05 = 0.45 kg BEE-2007 Paper-2:Set-A-Key 8 Paper – 2 – Set A- SOLUTION Percentage Sensible Heat Loss = mCp (Tf-Ta)/GCV = Percentage Latent Heat Loss = mh fg GCV = 0.45 0.45 (180 40) = 0.52% 5500 0.45x 584 = 4.78% 5500 S-10 Explain the working of a float trap with a sketch. or Float traps operate in a very similar way to a ball cock. A float contained within the trap body is raised or lowered by the volume of condensate delivered to the trap. As increasing levels of condensate raise the ball float, the mechanism lifts a valve allowing condensate to discharge thus lowering the level of condensate within the trap. The trap eventually closes preventing the further passage of steam. The trap will remain closed and partially flooded unless there is a sufficient level of condensate within the trap. At start up any air ahead of the steam and condensate will not therefore be vented. Consequently it is necessary to incorporate an air cock or a balanced pressure device (as described above) to release air in the trap. BEE-2007 Paper-2:Set-A-Key 9 Paper – 2 – Set A- SOLUTION Long questions L-1 A steam pipeline of 100mm diameter is not insulated for 100 metre length, supplying steam at 10 kg/cm 2.Find out the fuel savings if it is properly insulated with 50mm insulating material.Assume 8000 hours of operation per year. Given: Boiler efficiency :80% Cost of fuel oil :Rs20,000/tonne. Gross Calorific value of fuel :10300k.cal/kg Surface temperature without insulation :1700C Surface temperature after insulation :500C Ambient temperature :300C Existing Heat Loss: Surface heat loss S= 10+(Ts –Ta)/20 x(Ts-Ta) Where Ts =Hot surface temperature0C Ta =Ambient temperature0C S =Surface heat loss in k.Cal/hrm2 Substituting values S= 10+(170 –30)/20 x(170-30) =2380 k.Cal/ hr-m2 Modified System : After insulating with 50mm insulating material the surface temperature has reduced to 500C Substituting values S= 10+(50 –30)/20 x(50-30) =220 k.Cal/ hrm2 Calculation of Fuel savings: Pipe dimension =100 metre length and 100mm diameter Surface area existing =3.14x 0.1x 100 =31.4 m2 Surface area after insulation =3.14x0.2x100 =62.8 m2 Total heat loss in existing system =2380x31.4 =74732 k.Cal/hr Total heat loss in modified system=220x62.8 =13816 k.Cal/hr Reduction in heat loss =74732-13816 =60916 k.Cal/hr No of operating hours per annum =8000 Savings in heat per year BEE-2007 Paper-2:Set-A-Key =60916x8000 =487328000 k.Cal/year 10 Paper – 2 – Set A- SOLUTION Annual savings in fuel oil =487328000/(10300x0.8)x1000 = 59.142Tons Monetary savings per annum =59.142x20000 =Rs11.83 lakhs L-2 Compare the cost of power generation from a gas turbine installed with a 10 TPH wast heat recovery boiler vis-a-vis grid supply. The operational data are as under: Capacity of gas turbine :5000kW Auxiliary power consumption :1% Operating hours per annum :8000 Plant load factor :90% Heat rate : 3050k.Cal/kWh Calorific value of natural gas : 9500k.Cal/sm3 Cost of gas :Rs.6000/1000 sm3 Cost of capital and operation W.H.R charges per annum of gas turbine and boiler : Rs.600 lakhs Cost of electric power from grid :Rs 4.5/kWh (Demand and energy charges) Power generation from Cogeneration plant 5000x(90/100)x8000 =360x105 kWh Auxiliary power consumption 1% 360x105 x 0.01 3.6 x 105 360x105 - 3.6 x 105 356.4 x 105 Net power generated Natural gas required for above generation (360 x 105)x3050/9500 115.57 x105 sm3 Cost of fuel per annum 115.57 x105 x6000/1000 693.42 lakhs Cost of capital and operation charges Total cost of power from Cogeneration plant Rs 600 lakhs 693.42 + 600 1293.42 lakhs Cost of Cogenerated power Rs1293.42/356.4 =Rs3.63/kWh Cost of grid power Rs 4.50/kWh Cost of cogeneration power is cheaper by Rs 0.87/kWh BEE-2007 Paper-2:Set-A-Key 11 Paper – 2 – Set A- SOLUTION L-3 An oil fired boiler uses furnace oil with ultimate analysis of Sulpher 3%, Hydrogen 12%, Carbon 84% and oxygen 1% and gross calorific value of 10,268 kcal/kg. The boiler furnace is operated with 15% excess air at 27ºC and humidity ratio 0.0175. If the flue gas temperature is 280ºC, determine the dry flue gas losses and latent heat loss due to evaporation of water. Ans. For 100 kg of oil Combustion of carbon C + O2 = CO2 32 Theoretical O2 required = x 84 = 224 kg 12 44 CO2 produced = x 84 = 308 kg 12 Combustion of hydrogen 2H2 + O2 = 2H2O 32 Theoretical O2 required = x 12 = 96 kg 4 36 H2O produced = x 12 = 108 kg 4 Combustion of sulphur S + O2 = SO2 32 Theoretical O2 required = x 3 = 3 kg 32 64 SO2 produced = x 3 = 6.0 kg 32 Theoretical O2 required = 224 + 96 + 3 = 323 kg 1% already available in fuel. So net oxygen required is 322 kgs. Excess O2 required = 322 x 0.15 = 48.3 kg Total O2 required = 322 + 48.45 = 370.3 kg 77 Accompanied N2 = 370.3 x = 1239.7 kg 23 Accompanied moisture = (1239.7 + 370.3) x 0.0175 = 28.18 kg Dry flue gas loss = [(308 + 6 + 48.3 + 1239.7) x 0.23 x (280-27) = 93320.3 kcal Latent heat loss = 108 x 584 = 63,072 kcal L4 Explain briefly the principal of operation of a) Heat pipe BEE-2007 Paper-2:Set-A-Key 12 Paper – 2 – Set A- SOLUTION The Heat Pipe comprises of three elements – a sealed container, a capillary wick structure and a working fluid. The capillary wick structure is integrally fabricated into the interior surface of the container tube and sealed under vacuum. Thermal energy applied to the external surface of the heat pipe is in equilibrium with its own vapour as the container tube is sealed under vacuum. Thermal energy applied to the external surface of the heat pipe causes the working fluid near the surface to evaporate instantaneously. Vapour thus formed absorbs the latent heat of vapourisation and this part of the heat pipe becomes an evaporator region. The vapour then travels to the other end the pipe where the thermal energy is removed causing the vapour to condense into liquid again, thereby giving up the latent heat of the condensation. This part of the heat pipe works as the condenser region. The condensed liquid then flows back to the evaporated region. b) Radiation Repuperator A metallic radiation recuperator consists of two concentric lengths of metal tubing. The inner tube carries the hot exhaust gases while the external annulus carries the combustion air from the atmosphere to the air inlets of the furnace burners. The hot gases are cooled by the incoming combustion air which now carries additional energy into the combustion chamber. Radiation recuperator gets its name from the fact that a substantial portion of the heat transfer from the hot gases to the surface of the inner tube takes place by radiative heat transfer. BEE-2007 Paper-2:Set-A-Key 13 Paper – 2 – Set A- SOLUTION c) Plate heat exchanger Ans. A plate type heat exchanger consists of a series of separate parallel plates forming thin flow pass. Each plate is separated from the next by gaskets and the hot stream passes in parallel through alternative plates whilst the liquid to be heated passes in parallel between the hot plates. To improve heat transfer the plates are corrugated. Hot liquid passing through a bottom port in the head is permitted to pass upwards between every second plate while cold liquid at the top of the head is permitted to pass downwards between the odd plates. When the directions of hot & cold fluids are opposite, the arrangement is described as counter current. L5 List 10 energy saving measures in a steam system 1. Monitoring Steam Traps 2. Avoiding Steam Leakage 3. 4. Providing Dry Steam for Process Proper Utilisation of Directly Injected Steam 5. Miminising Heat Transfer Barrier 6. Proper Air Venting 7. Condensate Recovery 8. Insulation of steam pipe lines and hot process equipments 9. Flash Steam Recovery BEE-2007 Paper-2:Set-A-Key 14 Paper – 2 – Set A- SOLUTION 10. Reducing the work to be done by steam BEE-2007 Paper-2:Set-A-Key 15