Shahzad-Resume

advertisement

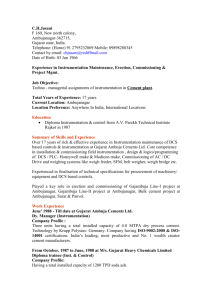

SHAHZAD AHMED To obtain a distinguishing position in the field of Instrumentation & Control Engineering with an insight vision of getting well rounded and comprehensive skills in the areas of Instrumentation & Control that can provide a sound basis for my career. P E R SO N AL I N FO RM ATI O N Date of Birth: Marital Status: Permanent Address: Phone: E-mail: October 11, 1982 Married FF-03, Block 37-D, PHA Flats, GT Road, Lahore (92) (345) 7775166, (92) (42) (35033133) schezad.ahmed@gmail.com WORK EXPERIENCE (Total Experience: 7 years) HIGHLIGHTS OF EXPERIENCE Presently working with MOL Pakistan Oil & Gas Co. B.V., a Netherlands incorporated E&P Company, at its Manzalai Field Development Central Facility (CPF), TAL Block, District Karak, NWFP, Pakistan. At present leading instrumentation and control department at Central Processing Facility (300 MMSCFD and 8000 BPD crude processing facility). Good team leadership and management skills. Experience of Project Execution Cycle right from proposal, contract preparation, execution and control. Experience of OPEX and CAPEX budget allocation and optimization of spares inventory. Commissioning and Project supervision experience of 300 MMSCFD and 8000 BPD processing facility. Experience of modern instrumentation & Controls including DCS,ESD,BMS, SCADA/Telemetry and PLC systems Participated in the HAZOP, PHA and SIL assessment of oil and gas processing facilities. Commissioning experience of Electrical, instrumentation and control setup/equipments of Manzalai-1 Gas Plant, Makori-1 crude production facility and Central Processing Facility while working with MOL. Analysis, fault diagnosis, and troubleshooting of complex and re-accruing problems related to Instrumentation and Control especially regarding DCS, HMI, ESD, PLCs, Flow computer, gas chromatography and F&G System. Excellent knowledge of ERP/CMMS system , specially worked on Plant maintenance, Project System and Material Management Modules. Good working experience of various transmitters, control valves, temperature, pressure, flow and level measuring devices, positioners, proxy sensors, heat detectors, UV detectors, gas sensors, flame detectors etc. Good knowledge of international standards pertaining to I & C e.g. NEC, ISA, IEC, AGA PROFESSIONAL PROFILE MOL Pakistan Oil and Gas CO.B.V. (Nov. 2005 to the date) MOL Pakistan is incorporated in Netherlands and is a subsidiary of MOL Hungary Plc. MOL Pakistan is an Exploration and Production Company, working in TAL block (N.W.F.P.). MOL has a setup of hydrocarbon dew point control & water dew point control for 420 MMscfd of Natural gas and 10,000 BPD of condensate stabilization. 1 of 4 I joined MOL Pakistan in Production Department which is responsible for the Gas processing plant operations, smooth supply of Natural Gas to SNGPL and stabilized condensate supply to refinery. I&C Section Lead (Central Processing Facility) (April 2010 to the date) Presently, leading Instrumentation and Control System Section at Central Processing Facility ( 300 MMSCFD and 8000 BPD processing facility). My team includes 04 assistant engineers and 12 instrument technicians. Here my key job responsibilities are Analysis, fault diagnosis, and troubleshooting of problems related to Electrical, Instrumentation & Control especially regarding DCS, ESD, Flow computers, MPFMs, gas chromatograms, F&G, CCTV and Anti-intrusion system. Joint Monthly calibrations with SNGPL regarding custody transfer equipment calibrations and validations. Prepare plans for schedule maintenance to ensure smooth operation of instruments and reduce breakdown troubles. Prepare and manage annual OPEX and CAPEX budget for I&C Section. Maintenance of plant instrumentation and packaged control system installed at power generation system, Gas Compressors, BTEX and MRUs. Spare parts monitoring, scheduling, planning & cost estimation. Provide technical support to technicians of problems pertaining to field instrumentation and control room. Give presentations to the department members related to I & C, especially to the solutions of the critical faults diagnosis. Prepare safe maintenance procedures for schedule and common breakdowns. Prepare daily and monthly reports. Prepare technical evaluations of the proposed bids. Prepare indent justifications. Technical correspondence with the head office and different vendors. I&C Commissioning Lead (Jan. 2009 to March 2010) Led I&C section and supervised the instrumentation, Control System and Telecom/CCTV/Anti Intrusion system installation and construction activities at Central Processing Facility (a 300 MMSCFD and 4000 BPD crude oil processing facility). Here, I was responsible for the successful commissioning of the following systems along with other plant instrumentation Yokogawa Centum CS 3000 DCS for process control, with total IO count of 3500 including 30 serial I/Os of packaged/skid equipments. HIMA SIL 3 (PES/H51q) ESD System HIMA SIL 3 (H41q-HS) based Wellheads RTUs (07 Nos.) HIMA SIL 3 (H41q-HS) based gathering stations RTUs (04 Nos.) Wellhead Solar Power System (BP Solar) Daniel Gas Chromatographs 2350A (C6+ Application) Daniel Gas Chromatographs 2350A (C9+ Application) AMETEK Moisture Analyzer 3050 OLV ROCLINK-809 Flow Computer FloBoss S600 Flow Computer Roxar Multiphase Flow Meters 1900V (05 Nos.) Enercon Control System for Catterpillar Gas and Diesel Driven Power Generators Allen Bradley Control System for 04 Flash Gas and 03 Sales Gas Booster Compressors. Single mode fiber optics based SCADA, protocol MODBUS TCP with Ring and Star network topologies CCTV cameras and Anti-Intrusion System for Central Facility, Wellheads and Gathering Stations 2 of 4 E&I Section Lead (Manzalai-1 Gas Plant) (Jan. 2007 to Dec. 2008) Following were my major job responsibilities at MGP Analysis, fault diagnosis, and troubleshooting of problems related to Electrical, Instrumentation & Control especially regarding CCS, ESD, Flow computer, gas chromatography and F&G. Joint Monthly calibrations with SNGPL regarding custody transfer equipment calibrations and validations. Prepare plans for schedule maintenance to ensure smooth operation of instruments and reduce breakdown troubles. Maintenance of plant PLCs and DCS. Spare parts monitoring, scheduling, planning & cost estimation. Provide technical support to technicians of problems pertaining to field instrumentation and control room. Give presentations to the department members related to E, I & C, especially to the solutions of the critical faults diagnosis. Prepare safe maintenance procedures for schedule and common breakdowns. Prepare daily and monthly reports. Prepare technical evaluations of the proposed bids. Prepare indent justifications. Technical correspondence with the head office and different vendors. Instrument Commissioning Team Member (Makori-1 EPF) Dec. 2006) (May 2006 to Participated in the erection, commissioning and smooth operation of Makori-1 crude oil facility (28 MMSCFD gas and 6000 BPD crude oil production facility) Makori-1 E&I systems are almost same as that of Manzalai-1 Gas Plant. Manzalai-1 Gas Plant Commissioning Team Member (Nov. 2005 to May 2006) Actively participated in the erection, commissioning and smooth operation of Manzalai-1 Gas Plant (50 MMSCFD gas processing plant) I was involved in the installation and successful commissioning of following systems Allen Bradley Control Logix 5000 PLC based CCS (Central Control System) for main plant control and ESD system RS View32 & Wonderware HMI, SQL Server and Intellimax web server for historical reports Allen Bradley SLC 500 for Turbo-Expander Unit control MicroLogix-1200 for Well head Control RTU SCADA/Telemtery system (Wireless) with BP Solar system Daniel Gas Chromatographs 2350A AMETEK Moisture Analyzer 3050 OLV ROCLINK-809 Flow Computer APC online UPS Control system Global Thermoelectric TEG/CP System Terberg Controls for Caterpillar Gas/Diesel generators Techo-Westinghouse VSD for Glycol Circulation Pumps, ABB VSD for Propane refrigeration compressor. Siemens Micromaster 440 VSD for Flash gas compressor Murphy millennium controller for flash gas compressor control Active participation in pre-commissioning activities. 3 of 4 SIEMENS PAKISTAN ENGINEERING COMPANY LTD. (Nov. 2004 to Nov. 2005) Worked as Executive Engineer (Process Automation) in BU MES Worked as application/commissioning engineer on following projects Commissioning of control system for three 06 MW natural gas fired Wartsila engines at Crescent Energy Limited. Shakarganj Mills Ltd. Bhone (Distillery, ETP automation) Hamza Oil Mills, Sheikhupura (Deodorizer automation) Pakistan Cement, Chakwal (Comm. Of UPS) Pioneer Cement Ltd (Comm. of Protection Relays, Transducers) General responsibilities include; designing and commissioning of control systems, SAT and FAT conduction, internal sales, proposal preparation, technical evaluations, quotations preparation and correspondence with clients regarding different technical and commercial queries. H SE AW AR EN ESS Overall effective knowledge of HSE management systems pertaining to E&P sector such as: Permit to Work Emergency response system Incident reporting and investigation HSE meetings, safety talks and safety drills Contractor HSE issues and controls Operational HSE issues such as working at heights, vessel entry, crane safety, welding safety etc. Also have good awareness of hazards related to electrical/electronic equipments. Practical acquaintance of Recognition, Evaluation and Control of hazards specially related to Electrical, Instrumentation and control areas. SO FT W AR E INT ER ACT IO N MS Word, Excel, Project, Power Point Mechanical Design: AutoCAD 2000, Solid Edge 7.0 Computer Networking: Windows LAN and Eathernet Configuration, Pear/Pear networking Circuit Design & Analysis: EWB, CM2000, Protel. Programming Languages: C/C++, Visual C++, Matlab. GUI Development in VC++ and Matlab Embedded Systems, DCS & PLC: Standard IEC 61131-3 PLC Ladder Logic, FBD and ST programming for ABB’s KT 9X Programming for Siemens Sematic-S7 controller series Project development in Yokogawa CS3000 ELOP II for HIMA Safety PLCs Programming for ControlLogix 5000, RSView 32(Run & Works) & RS Linx of Allen Bradly Control System Series. Intouch’s Wonderware HMI Intellimax Server configuration Assembly Programming for PIC 16F84A & 16F877 RISC and Atml 89C51 Microcontrollers. Industrial Networks & Communication: Profibus (DP/PA), Industrial Ethernet, ControlNet, RS-232, RS-485, Modbus, Field Foundation Bus 4 of 4 PROFESSIONAL CERTIFICATIONS, MEMBERSHIPS & TRAININGS Member of following professional societies/institutes ISA (The Instrumentation, Systems, and Automation Society). Preparing for ISA-CAP (Certified Automation Professional) Certification. PMI (Project Management Institute), Preparing for PMP certification. Caterpillar Diesel and Gas engines operation & maintenance training by Allied Engineering & Services Pakistan. HIMA ESD System and Yokogawa CS3000 DCS training from Intech Process Automation, Houston, Allen Bradley PLC and Rockwell Control software (customized for MOL) training by M/s Engro Innovative Engineering & Automation Services Ltd. Allen Bradley, Rockwell (RS Logix 5000), Intouch Wonderware HMI and Intellimax Server training by M/s Intech Process Automation Inc. QUALIFICATION B.Sc Mechatronics and Control System Engineering from University of Engineering and Technology Lahore, Pakistan (2001-2004) HSSC Government College of Science, Faisalabad (1998-2000) SSC Government Technical High School, Faisalabad (1998) HOBBIES: Playing Table Tennis, Cricket and Badminton Reading articles related to science & technology. Very fond of History and Literature Net surfing 5 of 4