Word version

advertisement

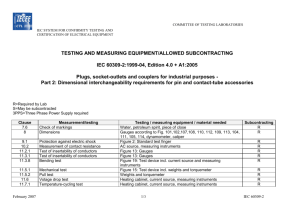

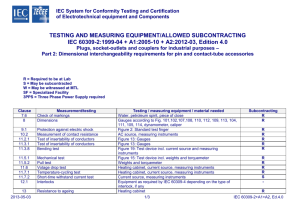

IEC SYSTEM FOR CONFORMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT COMMITTEE OF TESTING LABORATORIES TESTING AND MEASURING EQUIPMENT/ALLOWED SUBCONTRACTING Live working – Hand tools for use up to 1000 V a.c. and 1500 V d.c. IEC 60900:2004-01, Edition 2 R=Required by Lab S=May be subcontracted 3PPS=Three Phase Power Supply required Clause 5.2 4.1.4 5.3 4.3 5.4 5.4.1 Measurement/testing Visual check Marking (measurement of dimensions) Dimensional check Measurement of dimensions Impact tests Impact test 5.4.3 5.4.4 5.5 5.5.2.2 5.5.2.3 Low temperature impact test Extreme low temperature impact test Dielectric tests Water bath conditioning Wet chamber conditioning 2007-01-05 Testing / measuring equipment / material needed Subcontracting - Slide-gauge R - Slide-gauge R - Pendulum hammer test apparatus (Figure 8a – Method A), Test apparatus (Figure 8b – Method B) Cooling chamber (up to -25 °C) Cooling chamber (up to -40 °C) - Water bath - Wet chamber [alternative to 5.5.2.2] 1/4 R R R R R iec60900_ed2 IEC SYSTEM FOR CONFORMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT Clause 5.5.3 Measurement/testing Dielectric testing of insulated tools 5.5.3.1 Dielectric tests of tools capable of being assembled with square drives Dielectric testing of insulating tools (Figure 11) 5.5.4 5.6 Indentation test (insulated tools) 5.7 5.7.1 Test for adhesion of the insulating material coating (insulated tools) Conditioning 5.7.2 Test on the working head 2007-01-05 - - COMMITTEE OF TESTING LABORATORIES Testing / measuring equipment / material needed Water bath (Figure 9), Slide-gauge, Bath of nickel stainless steel balls 3 mm in diameter, Adjustable high voltage test equipment (AC) up to 10 kV, Stop watch, Current-measuring instrument Dummies (Figure 10 and Table 2) Slide-gauge, Adjustable high voltage test equipment (AC) up to 10 kV, Stop watch, Current-measuring instrument Hemisferic nose-piece, Rod, Weight (20 N), Heating chamber, Adjustable high voltage test equipment (AC) up to 5 kV, Stop watch - Heating chamber, Stop watch Hook (Figure 13a – Method A), Weight (50 N), Device with two cutting edges (Figure 13b – Method B) [alternative], - Weight (100 N) [alternative], - Stop watch, - Slide-gauge 2/4 Subcontracting R R R R R R iec60900_ed2 IEC SYSTEM FOR CONFORMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT Clause 5.7.3 Measurement/testing Test on the insulation of the blades of screwdrivers 5.7.4 Test of adhesion of the insulation of the entire tool 5.7.5 Test of adhesion of insulating covers of conductive adjusting or switching elements 5.8 5.9 5.9.1 5.9.2 (A.2)1) 5.9.2 (A.3)1) 2007-01-05 Flame retardancy test - COMMITTEE OF TESTING LABORATORIES Testing / measuring equipment / material needed Device with two cutting edges (Figure 14), Weights (up to 200 N), Stop watch, Slide-gauge Testing apparatus (Figure 15), Weights or dynamometer (up to 500 N), Stop watch Weights or dynamometer (up to 50 N), Stop watch, Water bath (Figure 9), Slide-gauge, Bath of nickel stainless steel balls 3 mm in diameter, Adjustable high voltage test equipment (AC) up to 10 kV Burner (Figure 16), Slide-gauge, Stop watch Mechanical tests Mechanical specifications for insulated hand tools Mechanical specifications for insulated hand tools shall comply with ISO Standards or the standard specified by manufacturer or customer (e.g. a national standard) Mechanical strength for insulating tools - Slide-gauge, (Annex A): Insulating screwdrivers – Torsion - Torque meter (up to 1 Nm) test Mechanical strength for insulating tools - Slide-gauge, (Annex A): Insulating wrenches and ratchets - Weights or dynamometer (up to 500 N) – Hand force test 3/4 Subcontracting R R R R S S S iec60900_ed2 IEC SYSTEM FOR CONFORMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT Clause 5.9.2 (A.4)1) 5.9.3 Measurement/testing Mechanical strength for insulating tools (Annex A): Insulating T-wrenches – Hand force test Mechanical strength for insulating tools (Annex A): Insulating pliers and cable shears (ISO 5744) – Hand load test Mechanical strength for insulating tools (Annex A): Gripping pliers with a flat nose (ISO 5744) – Torsion test Mechanical strength for tweezers 5.9.4 Retaining force test 5.10 Durability of marking 5.9.2 (A.5)1) 5.9.2 (A.5)1) 1) COMMITTEE OF TESTING LABORATORIES Testing / measuring equipment / material needed - Slide-gauge, - Weights or dynamometer (up to 250 N) Subcontracting S - Slide-gauge, - Testing apparatus suitable to apply up to 500 N S - S Slide-gauge, Testing apparatus suitable to apply up to 350 N, Testing apparatus suitable to apply a torque up to 4 Nm) Slide-gauge, Testing apparatus suitable to apply up to 10 N, Test piece Slide-gauge, Weights or dynamometer (up to 500 N), Stop watch Only chemicals, Stop watch S S R Annex informative Note: The presence of equipment alone does not indicate a satisfactory situation. Assessors must evaluate the equipment design, calibration, uncertainty and documentation to ensure compliance with the directions of the standard. The requirements of ISO Guide 25 regarding validation are applicable, as the tests of this standard are not standardized tests. 2007-01-05 4/4 iec60900_ed2