Dr Milind Kulkarni, India

advertisement

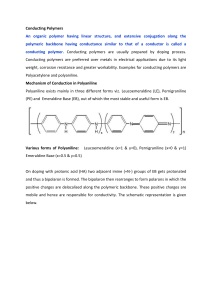

INK-JET PRINTABLE CONDUCTING POLYANILINE BASED INK: A PROMISING CANDIDATE FOR LOW COST, FLEXIBLE ELECTRONICS DEVICES Milind V. Kulkarni*, Bharat B. Kale, Sanjay K. Apte and S. D. Naik Nanocomposite Laboratory, Centre for Materials for Electronics Technology (C-MET), Department of Information Technology, Govt. of India Panchawati, Off Pashan Road, Pune 411 008, INDIA Corresponding Author E-mail address: milindcmet@yahoo.com /milind@cmet.gov.in Flexible electronics is the future trend of the worldwide electronic industry. Organic materials have attracted a lot of attention for building large-area, mechanically flexible electronic devices1. Organic light emitting diodes for flat panel displays are ready for mass production2 and significant progress has also been made in organic thin film transistors and organic solar cells3. There is a strong desire to develop new advanced materials that can overcome the potentially limiting scaling difficulties present in the semiconductor industry. Development of future information technology could come from data storage incorporating these advanced materials. Organic materials or polymers are promising candidates for electronic devices in new information technologies4. The use of these materials provides a simplified manufacturing process yielding low cost, flexible and light weight devices that have active device area approaching the nanoscale. Besides the obvious application of flexible electronics in flat panel displays. Flexible circuits are also promising for use in applications such as radio frequency identification (RFID) tags, low cost sensors, and other disposable electronic devices. In particular, devices based on organic semiconductors are considered to be very promising for these applications since they may potentially be fabricated entirely using printing technologies, eliminating the need for such major cost points lithography, vacuum processing including physical vapor deposition, plasma etching, and chemical vapor deposition (CVD), while simultaneously allowing the use of reel-toreel processing, resulting in reduced substrate handling and clean-room costs as well. Furthermore, since printing is inherently additive in nature, material and disposal costs are also expected to be reduced, resulting in an extremely low net system cost. In the last few decades, Synthetic Metals or Inherently Conducting Polymers (ICPs) have been very actively pursued. Several discoveries brought the ICPs to full commercialization with applications in displays, sensors, polymer light-emitting diodes, and photovoltaic and electrochromic devices5. Since the discovery of conducting polymers, they have become extremely attractive materials, due to their tunable band gaps and redox properties, processability, lightness, resistance against corrosion and low cost. Also, compare to silicon technology, polymers not only flexible, but costs less to the manufacturers. Among organic conducting polymers, polyaniline (Pani) is regarded as one of the most technologically promising electrically conductive polymers due to its ease of synthesis, low cost, versatile processability and relatively stable electrical conductivity 6. Inkjet printing is now an important technology for depositing layers of conductive polymers7. The method works by ejecting an ink through very fine nozzles, 10-200 μm diameter. The jetted stream is broken into a series of droplets that can be deposited on flexible and non flexible substrates. The advantages of inkjet printing over other thin film techniques lie in its patterning capability, the efficient use of material, the high speed and low cost of the process, and in the fact that thin films can be printed on flexible substrates. To print electronics, conducting ink is a key factor for the proper performance of printed electronics. In this report, we would like to present the synthesis of Ink-Jet Printable Conducting Polyaniline based ink and its Physico-chemical characterization and successive printing of IDT pattern on flexible untreated polymeric substrates. This conducting polymer based aqueous ink will have potential applications in low cost Sensors, Solar cells, Electrochromic Devices and in Printed, Flexible Electronics Devices. References: 1. R. H. friend, R. W. Gymer, A. B. Holmes, J. H. Burroughes, R. N. marks, C. Taliani, D. D. C. Bradley, D. A. Dos Santos, J. L. Bredas, M. Logdlund, W. R. Salaneck, Nature (1999), 397, 121. 2. W. E. Howard, Sc. Am. (2004), 290, 76. 3. C. J. Brabec, N. S. Sariciftici, J. C. Hummelen, Adv. Funct. Mater. (2001), 11, 15. 4. J. C. Scott, Science (2004), 304, 62. 5. M. F. Mabrook, C. Pearson and M. C. Petty, IEEE Sensor Journal (2006) 6, 1435 6. M. V. Kulkarni and A. K. Viswanath, Journal of Macromolecular Science, Part APure and Applied Chemistry, (2004) 41 No.10 1173. 7. K. E. Paul, W.S. Wong, S. E. Ready, R. A. Street, Appl. Phys. Lett. (2003) 83, 2070. (a) (b) (c) Fig.1 (a) Polyaniline based aqueous ink and (b, c) Ink-Jet printed IDT patter on untreated flexible polymer substrate Corresponding Author E-mail address: milindcmet@yahoo.com /milind@cmet.gov.in