View paper

advertisement

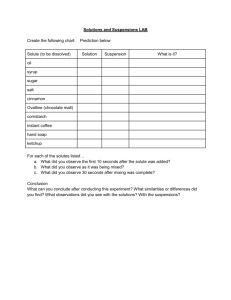

Anais do 45º Congresso Brasileiro de Cerâmica 0801901 30 de maio a 2 de junho de 2001 - Florianópolis – SC SELECTION OF DISPERSANTS FOR HIGH-ALUMINA ZERO-CEMENT REFRACTORY CASTABLES A.R. Studart, V.C. Pandolfelli Via Washington Luís, km 235, C.P. 676, CEP 13565-905, São Carlos-SP E-mail: pars@iris.ufscar.br ou vicpando@power.ufscar.br Universidade Federal de São Carlos, DEMa ABSTRACT The efficient dispersion of fine particles has been an essential requirement for developing refractory castables that can be easily installed and that exhibit superior performance at high temperatures. In addition to the optimization of rheological behavior, the dispersion of particles also enables a reduction of the admixing water content, resulting in castables with enhanced mechanical properties. Phosphate and polyacrylate salts are the additives most extensively used to disperse refractory castables through the well-known electrosteric stabilizing mechanism. Nevertheless, more efficient dispersants have been required in order to further reduce the admixing water content and, thus, facilitate and speed-up the castable de-watering process. The main objective of this paper is to establish some criteria for the appropriate selection of dispersants for high-alumina refractory castables. Results have shown that the molecule length, the charge density and the adsorption ability are the main features to be considered when selecting the dispersant. Key words: alumina, particles, refractory castable, dispersion, flowability. INTRODUCTION Several recent studies have shown the importance of the dispersion of matrix fine particles on the development of high-performance refractory castables (1-4). The appropriate dispersion of particles enables the production of highly fluid castables with minimal water additions, rendering refractory materials with superior mechanical properties before and after firing. Anais do 45º Congresso Brasileiro de Cerâmica 0801902 30 de maio a 2 de junho de 2001 - Florianópolis – SC Currently, efforts have been focused on attempts to further reduce the castable water content in order to facilitate the refractory de-watering process (5). This requires the use of more effective dispersants that could decrease the water content, keeping castable high flowability. Polyacrylate and phosphate salts have been the main additives used to disperse high-alumina castables. The adsorption of such molecules on the surface of particles gives rise to an electrical double layer and a steric layer that prevents agglomeration through the well-known electrosteric mechanism. In order to accomplish particle dispersion the thickness of these layers must be sufficiently high to overcome the action of the attractive van der Walls forces. The particle zeta potential after dispersant adsorption, the liquid ionic strength and the dispersant molecular length are the main factors that control the dispersion state of particles, since they determine the thickness of the steric and electric double layers. The main objective of this paper is to use these surface chemistry parameters as guidelines to properly select dispersants for high-alumina refractory castables. This would enable a reduction of the castable water content for a given flowability level, aiding the de-watering process and improving the castable mechanical properties. EXPERIMENTAL PROCEDURE (a) Dispersants Sodium polyacrylate (BASF S.A., Brazil) of varying molecular weight (1200, 2500, 5100, 8000 and 15000 g/mol) were utilized in this work to investigate the effect of the dispersant molecular length on the rheological behavior of concentrated alumina suspensions. Gallic acid (Mallinckrodt, USA), citric acid (6) (Labsynth, Brazil) and diammonium citrate (Fluka Chemie AG, Switzerland) were also evaluated. Electroacoustic measurements (DT-1200, Dispersion technology, Inc., U.S.A) were performed to assess the zeta potential of particles after dispersant adsorption. Such tests were accomplished in dilute suspensions (2 vol%) prepared by adding the powder and chemicals into distilled water, followed by ultrasonication for 15 min. The suspension pH was adjusted with small additions of HCl and NaOH, 1 – 2 N solutions. Anais do 45º Congresso Brasileiro de Cerâmica 0801903 30 de maio a 2 de junho de 2001 - Florianópolis – SC The thickness () of the steric layer formed around particles after dispersant adsorption (adlayer) was estimated from the polymer molecular weight (MW) in the case of polyacrylates, employing the equation suggested by Lewis et al. (7): 0.06M W 12 . (A) For citrate ions, this thickness was assumed to be of approximately 0.5 nm, as predicted by Leong et al. based on experimental results (8). (b) Alumina suspensions A highly pure alumina (Ceralox HPA-0.5, 8.9 m2/g, d50 ~ 0.5 m, Condea Vista, U.S.A.) was utilized to evaluate the dispersing behavior of the additives under very stable conditions in terms of ionic strength and particle size distribution. Suspensions prepared with this alumina were first ball-milled for 24 hours in order to promote particle de-agglomeration and, subsequently, degassed for 5 minutes (100 mbar) before rheological measurements proceeded. The rheological behavior of highly pure alumina suspensions prepared with different dispersants was analyzed under steady-stress conditions (CS-50 rheometer, Bohlin Instruments, UK), by applying a shear sweep between 0.06 and 500 s-1 in a total of 40 steps. Due to the high solid loading of the suspensions evaluated (50 – 58 vol%), the vane tool was utilized in all measurements as a means to prevent wall slipping. (c) High-alumina castables High-alumina castables were prepared using white fused alumina (EK8R, Alcoa, Brazil) as aggregates (~ 75 wt%) and the calcined aluminas A-3000 FL (~ 15 wt%) and A-1000 SG (~ 10 wt%) as the matrix constituents (Alcoa Chemicals, USA). The particle size distribution of such castables was adjusted to a theoretical curve based on Andreasen packing model (q = 0.21) (1,2), in order to obtain potentially self- flow compositions. An optimum mixing procedure was adopted to prepare castables, as described in a recent article by the authors (9). The free-flow test adapted from the ASTM 860 standard (1) was performed to provide an index of castable flowability. Anais do 45º Congresso Brasileiro de Cerâmica 0801904 30 de maio a 2 de junho de 2001 - Florianópolis – SC RESULTS AND DISCUSSION (a) Effect of adlayer thickness The steric layer (adlayer) thickness is known to display a dual effect on the rheological behavior of suspensions. At low solid loading, an increase in the adlayer thickness is expected to have a positive effect on the suspension rheology, as it prevents particle agglomeration through a pronounced steric mechanism. On the other hand, excessively thick steric layers usually cause an increase in the suspension effective concentration that can be high enough to abruptly increase the viscosity of suspensions with high solids content (10). Furthermore, the long-chain molecules necessary to provide thick steric layers may lead to a substantial increase in suspension viscosity, when they are not adsorbed on the particle surface and remain in the liquid medium (10). This ambiguous aspect of the adlayer thickness has motivated the evaluation of its effect on the rheological behavior of concentrated suspensions, in order to investigate whether there is an optimum thickness range for the efficient dispersion of refractory castables. Such evaluation was accomplished by first determining the effect of the dispersant content on the viscosity of 50 vol% alumina suspensions. Figure 1 presents the results obtained for suspensions containing diammonium citrate and sodium polyacrylates with different molecular weight. No evident correlation can be established between the polyacrylate molecular weight and their optimum dispersing content in terms of mg/m 2. However, Table I reveals that a correlation exists when the optimum content is calculated based on the number of molecules per surface area (mol/m2). It is observed that the amount of polyacrylate molecules necessary to minimize the suspension viscosity increases with the decrease of the dispersant molecular weight. Similar results were obtained by Leong et al. (11), who found that superior contents of dispersant (in mol/m 2) are required to shift zirconia isoelectric point (IEP), when the polyacrylate molecular weight is increased. A more impure alumina obtained from the Bayer process (A-1000 SG, 8.9 m2/g, d50 ~ 0.5 m, Alcoa Chemicals, USA) was also used in this study to assess the Anais do 45º Congresso Brasileiro de Cerâmica 0801905 30 de maio a 2 de junho de 2001 - Florianópolis – SC behavior of dispersants under the more unstable conditions normally encountered in refractory applications. In this case, the suspension were neither ball-milled nor degassed in order to reproduce the dispersing conditions of refractory castables. Ceralox HPA-0.5 Dispersants: 50 vol% suspensions -1 Apparent viscosity at 50 s (mPas) 10000 Diammonium citrate 1000 1200 2500 5100 100 Sodium Polyacrylate (g/mol) 8000 15000 10 0.1 0.2 0.3 0.4 0.5 0.6 Dispersant content (mg/m2) Figure 1: Apparent viscosity of 50 vol% alumina suspensions (Ceralox HPA-0.5) for different additions of diammonium citrate and sodium polyacrylates of varying molecular weight. Table I: Adlayer thickness (), isoelectric point shift (IEP) and ratio IEP/ expected (or obtained) after addition of distinct dispersants at their optimum contents into alumina suspensions (Ceralox HPA-0.5). Sodium polyacrylate (g/mol) Diammonium Gallic citrate 1200 2500 5100 8000 15000 acid 0.26 0.34 0.31 0.30 0.46 0.50 - (1.150) (0.283) (0.124) (0.059) (0.057) (0.033) (nm) 0.5 – 0.8 2.1 3.0 4.3 5.4 7.3 0.5 – 0.8 IEP 4.6 4.0 4.0 3.9 5.2 5.2 4.2 IEP/ (nm-1) 5.6 – 9.3 1.9 1.3 0.9 1.0 0.7 5.3 – 8.4 Optimum content in mg/m2 (mol/m2) expected range. data obtained from reference (13). Anais do 45º Congresso Brasileiro de Cerâmica 0801906 30 de maio a 2 de junho de 2001 - Florianópolis – SC Suspensions prepared with Bayer-process alumina required dispersant contents slightly lower than those presented in Table I to achieve minimum viscosity. This was attributed to the fact that these slurries were not ball-milled before measurements, which might have resulted in the presence of agglomerates in these suspensions. Except for this slight difference in the optimum dispersant content, the rheological behavior of these suspensions was in general very similar to that obtained for slurries containing highly pure alumina. Electroacoustic measurements revealed that the addition of optimum contents of ammonium citrate and sodium polyacrylate (Table I) gives rise to zeta potential values as high as 45 - 60 mV in the pH range of castables (8-10). Such optimum contents were utilized for the preparation of alumina suspensions at higher solid loadings, in order to compare their rheological properties at the best dispersing conditions. At these conditions, the dispersants are assumed to have covered most of (or even all) the surface area of particles. Figure 2 shows the viscosity results obtained for highly concentrated 10000 Sodium polyacrylate Range I -1 Apparent viscosity at 50 s (mPa.s) suspensions (50 – 58 vol%) as a function of the dispersant adlayer thickness. Solid loading (vol%): Range II 1000 50 55 100 58 Suspensions with optimum dispersant content Diammonium citrate 10 0 1 2 3 4 5 6 7 8 Adlayer thickness (nm) Figure 2: Effect of the dispersant adlayer thickness on the apparent viscosity of highly concentrated alumina suspensions (Ceralox HPA-0.5) dispersed either with ammonium citrate or sodium polyacrylates of varying molecular weight. In the case of the polyacrylate series, two different ranges of adlayer thickness () may be distinguished in terms of the effects observed on the suspension viscosity. Anais do 45º Congresso Brasileiro de Cerâmica 0801907 30 de maio a 2 de junho de 2001 - Florianópolis – SC In the lower range (~ 2 – 4.5 nm), the reduction of the adlayer thickness results in a gradual increase in viscosity, due probably to the decrease of the steric contribution to dispersion. On the other hand, in the higher range (~ 4.5 – 7.5 nm), a viscosity increase is observed as the adlayer becomes thicker. This may be attributed to the increase of the suspension effective concentration, as well as the occurrence of several other viscosity-increasing effects usually imparted by non-adsorbed longchain molecules (bridging, depletion, entanglement) (10,12). As a result of these distinct ranges, an intermediate adlayer thickness of approximately 4 nm seems to be the most appropriate for reducing the viscosity of concentrated suspensions (50 - 58 vol%) containing sodium polyacrylate as dispersant. Viscosity results obtained for suspensions containing optimum amount of diammonium citrate are also presented in Figure 2. Surprisingly, the addition of diammonium citrate resulted in suspensions with quite low viscosity, in spite of the very thin adlayer formed around particles in this case. A more detailed examination of these apparently contradictory results gives evidence to a major feature that molecules must display to work as effective dispersants for highly concentrated suspensions. Table I compares the shift in the alumina isoelectric point (IEP) obtained after adsorption of different dispersants. This parameter may be considered as an indicative of the molecule ability to incorporate electrical charges onto the particle surface. One can notice that the IEP shift accomplished with citrate ions is slightly higher than that obtained with low-molecular-weight polyacrylates ( 5100 g/mol). Such superior IEP shift is expected to compensate the thin layer of citrate ions formed around particles, enhancing the magnitude of electrostatic repulsive forces in detriment of the steric contribution to dispersion. Although this special feature of citrate ions may not lead to significant changes in the rheological behavior of less concentrated suspensions ( 50 %vol), it has a major impact at higher solid loadings (> 50 vol%), where the presence of thicker adlayers tend to increase the suspension viscosity (Figure 2). This becomes evident when the efficiency of these dispersants is evaluated under very high solid loading conditions in high-alumina castables, as shown in Figure 3. It is observed that castables containing sodium polyacrylate with optimum molecular weight (5400 Anais do 45º Congresso Brasileiro de Cerâmica 0801908 30 de maio a 2 de junho de 2001 - Florianópolis – SC g/mol) displayed free-flow values inferior than 10%, whereas those prepared with citric acid achieved flowability 8 times higher, with values in the self-flow range (80 110%). Figure 3 also points out that the flowability of castables dispersed with citric acid is still markedly higher than that of compositions containing sodium polyacrylate even when prepared with lower water content. 100 Gallic acid (14 vol% water) Free-flow (%) 80 Citric acid (15 vol% water) Citric acid (14 vol% water) 60 40 Sodium polyacrylate - 5400 g/mol (15 vol% water) 20 0 0.1 0.2 0.3 0.4 0.5 Dispersant content (mg/m2) Figure 3: Flowability of castables as a function of the content of different dispersants for distinct water additions. The effectiveness of citrate ions as charge generators on the surface of particles may be attributed to its higher number of dissociable sites per chain length (~ 0.80 sites/Å) in comparison to that of polyacrylate ions (~ 0.38 sites/ Å). It is also worthy mentioning that the short length of citrate chains impedes these molecules to display the spatial configurations (tails, loops and trains) normally expected from polyacrylate chains on particle surface. Therefore, one may suppose that citrate molecules tend to pack better on the surface of particles, since they are not able to develop opened conformations as in the case of polyacrylates molecules. This might be another factor that could contribute for the high efficiency of citrate ions as surface modifiers. Anais do 45º Congresso Brasileiro de Cerâmica 0801909 30 de maio a 2 de junho de 2001 - Florianópolis – SC (b) Short-chain highly-charged dispersants It becomes clear from the above considerations that the ratio IEP/ must be maximized if an effective dispersant for highly concentrated suspensions (or castables) is aimed. This parameter takes into account two of the main factors that control the rheological properties of suspensions, namely zeta potential and the adlayer thickness. However, the ionic strength has also a major influence on these properties and, thus, must also be considered when selecting a dispersant. Dispersants may increase the ionic strength of suspensions if a significant portion of their molecules is not adsorbed on the surface and remains in the liquid medium. This can be avoided by choosing dispersants that adsorb to a large extent over the pH range of interest. Hidber et al. (13) have shown that the adsorption behavior of organic short- chain molecules on alumina surface is determined by the dissociation constants (pKa values) of the molecule functional groups. Maximum adsorption is observed in the pH range that corresponds to the pKa values of the dissociable groups. The adsorption behavior of citrate and polyacrylate molecules on alumina surface displays similar pH dependence, as both dispersants possess several carboxylic groups (-COOH) along their molecular chain (Figure 4). The typically low pKa values of these groups (i.e., 5.82, 4.50 and 3.48 for citric acid three (-COOH) groups) lead these molecules to adsorb more prominently in the acid pH range, as illustrated in Figure 5 by data after Hidber et al. (13). Therefore, a significant amount of citrate and polyacrylate ions are expected to remain in the liquid medium and increase its ionic strength at the usual pH range of high-alumina castables. ~5Å HOOC HO COOH ~ 2.6 Å COOH COOH OH CH CH2 COOH n OH Citric acid Polyacrylic acid COOH OH 2,3,4-Trihydroxybenzoic acid HO OH OH Gallic acid Figure 4: Molecular structure of the dispersants evaluated. Anais do 45º Congresso Brasileiro de Cerâmica 0801910 30 de maio a 2 de junho de 2001 - Florianópolis – SC In contrast to the (-COOH) groups, hydroxyl groups usually display significantly higher pKa values (typically > 9) (13) and, thus, seem to be more suitable for dispersing high-alumina castables. Figure 5 shows that a benzoic acid containing three (-OH) side groups (2,3,4-trihydroxybenzoic acid) adsorbs in a large extent (> 90%) in the pH range of alumina castables, which would result in minimal increase of Adsorbed content / Added content (%) the liquid ionic strength. 100 Usual pH range of highhigh-alumina castables 80 60 Citric acid 40 2,3,4-Trihydroxybenzoic acid 20 4 5 6 7 8 9 10 pH Figure 5: Adsorption behavior of citric acid and 2,3,4-trihydroxybenzoic acid on alumina surface as a function of pH (data obtained by Hidber et al. (13)). The efficiency of molecules with hydroxyl groups on dispersing alumina castables was assessed in this work by evaluating the dispersing ability of gallic acid. Gallic acid is the name commonly used for the 3,4,5-trihydroxybenzoic acid, whose structure is illustrated in Figure 4. The chain length and IEP shift obtained with gallic acid are comparable to those of citric acid, which enables this compound to be a potential dispersant for highly concentrated suspensions. The absence of (-OH) groups in the ortho position of the benzene ring (Figure 4) is expected to further aid the adsorption of gallic acid on alumina in comparison to that of the 2,3,4trihydroxybenzoic acid, since this steric configuration prevents the occurrence of unfavorable electrostatic repulsion between the carboxylate ion and the alumina surface (13). Anais do 45º Congresso Brasileiro de Cerâmica 0801911 30 de maio a 2 de junho de 2001 - Florianópolis – SC Figure 3 shows that castables prepared with gallic acid can achieve higher flowability levels than that of compositions containing citric acid for the same water content, confirming the superior efficiency of gallic acid as a dispersant for alumina castables. This indicates that the use of gallic acid enables further reductions of the castable water content, which aids the refractory de-watering process. Stability maps of 58vol% alumina suspensions dispersed with citric acid and gallic acids were built in this study, following the procedure described elsewhere by the authors (2) (Figure 6). It can be noticed that the superior adsorption ability of gallic acid at alkaline pH conditions results in matrix suspensions displaying inferior viscosity in the pH range of high-alumina castables, which explains the flowability results presented in Figure 3. 0.35 (a) Citric acid 0.30 0.25 Dispersant content (mg/m2) 0.35 0.20 Viscosity (mPa.s) 0.30 0.15 Castable initial pH 0.25 0.10 0.20 0.35 180 210 6 7 8 9 10 11 12 250 300 0.15 0.30 0.10 0.25 400 pH inicial do concreto 6 7 8 9 0.15 11 12 pH (b) Gallic acid 0.20 10 Castable initial pH 0.10 6 7 8 9 10 11 12 pH Figure 6: Stability maps of 58 vol% alumina suspensions dispersed with (a) citric and (b) gallic acids. These maps show iso-lines that delineate the dispersant content–pH combinations necessary to provide suspensions with a given viscosity level. Anais do 45º Congresso Brasileiro de Cerâmica 0801912 30 de maio a 2 de junho de 2001 - Florianópolis – SC CONCLUSIONS This paper showed that the appropriate selection of dispersants can significantly reduce the castable water content for a given flowability level and, therefore, may be considered as a crucial step for speeding-up the refractory dewatering process. It was observed that the use of long-chain molecules could markedly deteriorate castable flowability properties. Therefore, efficient dispersants would be those that associate minimum chain length with maximum surface modifying ability (high IEP/ ratio). These features are most likely encountered in molecules presenting a high number of dissociable groups per chain length. The nature of the dissociable groups is another major factor that influences the dispersant efficiency, since it controls the molecule adsorption behavior as a function of pH. The aim in this case should be to choose dissociable groups that lead to maximum adsorption over the pH of castables, minimizing the dispersant negative effect on the liquid ionic strength. This can be accomplished by selecting dispersants containing functional groups with dissociation constants (pKa values) similar to the pH values expected for high-alumina refractory castables. ACKNOWLEDGEMENTS The authors would like to acknowledge FAPESP and Alcoa / Brazil for the financial support to this work. REFERENCES (1) A.R. Studart; W. Zhong, R.G. Pileggi, V.C. Pandolfelli, Am. Ceram. Soc. Bull. 77, 12 (1998) 60. (2) A.R. Studart, W. Zhong, V.C. Pandolfelli, Am. Ceram. Soc. Bull. 78, 5 (1999) 65. (3) A.R. Studart, W. Zhong, R.G. Pileggi, P. Bonadia, V.C. Pandolfelli, Am. Ceram. Soc. Bull. 79, 2 (2000) 49. (4) A.R. Studart, V.C. Pandolfelli, Am. Ceram. Soc. Bull. 79, 10 (2000) 53. (5) M.D.M. Innocentini, C. Ribeiro, L.R.M. Bittencourt, V.C. Pandolfelli, submitted to the J. Am. Ceram. Soc. (2001). (6) P.C. Hidber, T.J. Graule, L.J. Gauckler, J. Am. Ceram. Soc. 79, 7 (1996) 1857. (7) J.A. Lewis, H. Matsuyama, G. Kirby, S. Morissette, J.F. Young, J. Am. Ceram. Soc. 83, 8 (2000) 1905. Anais do 45º Congresso Brasileiro de Cerâmica 0801913 30 de maio a 2 de junho de 2001 - Florianópolis – SC (8) Y.K. Leong, P.J. Scales, T.W. Healy, D.V. Boger, R. Buscall, J. Chem. Soc. Faraday Trans. 89, 14 (1993) 2473. (9) R.G. Pileggi, A.R. Studart, J. Gallo, V.C. Pandolfelli, submitted to the Am. Ceram. Soc. Bull. (2000). (10) A.R. Studart, J. Gallo, V.C. Pandolfelli, submitted to the Am. Ceram. Soc. Bull. (2000). (11) Y.K. Leong, P.J. Scales, T.W. Healy, D.V. Boger, Colloids and Surfaces A. 95 (1995) 43. (12) V.A. Hackley, J. Am. Ceram. Soc. 81, 9 (1998) 2421. (13) P.C. Hidber, T.J. Graule, L.J. Gauckler, J. Eur. Ceram. Soc. 17 (1997) 239.