Aqueous 47 vol% suspensions of mixtures of alumina and zircon

advertisement

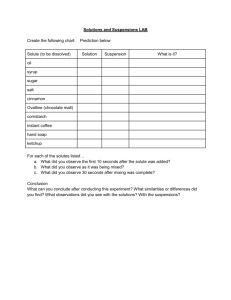

Anais do 44º Congresso Brasileiro de Cerâmica 37901 31 de maio a 4 de junho de 2000 - São Pedro – S.P. EFFECT OF RHEOLOGY ON GREEN DENSITY OF ZIRCON-ALUMINA CASTS. L.B. Garrido* and E.F. Aglietti** CETMIC. Centro de Tecnología de Recursos Minerales y Cerámica (CIC-CONICETUNLP). Cno. Centenario y 506. C.C.49 (1897) M.B. Gonnet. Buenos Aires. ARGENTINA. E-mail:garridol@netverk.com.ar ABSTRACT Rheological properties of aqueous suspensions (48 vol%) of zircon-alumina mixtures containing different amounts of polyelectrolyte as dispersant were studied. Slip casting in a plaster mould and pressure filtration at 8 MPa experiments were performed to correlate the rheological properties of the suspensions with the relative density of green casts. Flow curves fitted satisfactorily to the Casson model. The Casson viscosity values remained nearly constant whereas Casson yield stress parameter decreased to a minimum and then increased with increasing the amount of dispersant added. Although green densities decreased as yield stress Casson parameter increased, some suspensions having low apparent viscosity and small yield stress produced casts with slightly higher relative density values. This is attributed to a slight higher viscosity at low shear rates of these suspensions in which segregation of the particles and /or migration of the fines can not occur. Key words: Zircon, alumina, rheology, slip casting, pressure filtration. INTRODUCTION Reaction sintering of alumina and zircon is a common route to obtain a mullitezirconia composite. Several studies showed that materials composed of mullite and zirconia may be obtained using alumina and zircon powders by the traditional method that consisted in: premix milling, dry-pressing operations to produce the compacts and sintering. However, as the mean diameter of these powders are large, the achieved * CONICET Research member ** CONICET-UNLP Research member Anais do 44º Congresso Brasileiro de Cerâmica 37902 31 de maio a 4 de junho de 2000 - São Pedro – S.P. density was relatively low (1). To improve densification very fine powders must be chosen as densification must occur before mullitization (2). A high solid concentration of fines particles that are necessary in processes such as slip casting or pressure filtration often produced slips which are difficult to cast. In concentrated suspensions, the rheological behavior is mainly dominated by hydrodynamic effects, Brownian motion, electrostatic and steric repulsion and Van der Waal’s attraction. With large particles (or hard-sphere systems) the colloidal interparticle forces may be ignored and the contribution to rheology of the hydrodynamic effects depend on their volume concentration, shape, size, relative orientation and position (3-5) . The particle size distribution is an important parameter for these concentrated suspensions, acting mainly on the maximum volume fraction. The small particles fit the interstices between large ones. Thus to achieve a high particle packing efficiency and to minimize the viscosity bimodal or a continuous broad particle size distribution are used. As the particle size decreases to the colloidal range, flow behavior is strongly influenced by interparticle colloidal interactions as repulsion and Van der Waal’s attraction that control spatial arrangement (network structure) and dynamics of the suspended particles. Thus, an extra increase in viscosity and a complex rheological behavior are observed as a result of the formation of flocs due to relatively high van der Waals attraction as compared with the repulsion force. Certainly, flocculation has a considerable effect on size and shape of the flocs. By enclosing and thus immobilizing some liquid in the flocs have the effect of the increase the effective solid volume and though the viscosity of the suspension (3-5). Particle flocculation in the suspension leads to a low packing density because the flocs can not be close packed. However, welldispersed particles in the suspension optimize the rheological properties and the packing density of the cast. In this work, a polyacrylate based dispersant was used to control the degree of dispersion (to improve the rheology) of concentrated aqueous suspensions of aluminazircon mixtures. The effects of the amount of dispersant added and the different powder compositions on the rheological properties and on the green density of compacts obtained by slip casting and pressure filtration at 8 MPa were studied. Anais do 44º Congresso Brasileiro de Cerâmica 37903 31 de maio a 4 de junho de 2000 - São Pedro – S.P. MATERIALS AND METHODS Starting powders used in this study were commercially available -Al2O3 and ZrSiO4. The mean particle size were 0.5 and 1.8 m, respectively. The specific surface area (BET) was 9.5 m2/g for -Al2O3 (6) and 4.1 m2/g for zircon. Powder compositions of different alumina/ zircon (wt% ) ratios in the mixtures ( 45.5/54.5, 51.7/48.3 and 35.1/64.9) were studied. These proportions correspond to: a) stoichiometric, b) with a 6 wt% excess of alumina, and c) with a 10 wt% of zircon excess, respectively. The stoichiometric alumina-zircon ratio is which after a theoretical complete reaction at high temperature a mullite-zirconia composite is obtained. Aqueous 48 vol% suspensions were prepared by adding the powder to aqueous solutions with different polyacrylate content (Dolapix CE64, Zschimmers and Schwartz) at pH 9.1-9.2. After mixing, the suspensions were dispersed by ultrasonic process for 30 min. Flow curves of the suspensions were obtained using a rotational viscometer Haake vt550 of coaxial cylinders with NV measure system at 25°C. The consolidation of suspensions by slip casting was carried out in a plaster mould to produce samples in a form of bars (12x12x60 mm 3). Pressure filtration was made on a metallic sintered porous filter with a wet filter paper placed on it and uniaxial pressure was employed. A pressure of 8 MPa was applied from the top and the liquid moved through the porous filter. Pressure was maintained constant for 30 min. Cylindrical cast samples (25 mm diameter and 10-15 mm thick) were obtained. Bars and cylindrical compacts were dried 24 h at room temperature and then at 110 C up to a constant weight. Relative density (% of the theoretical) was measured by Hg immersion. Anais do 44º Congresso Brasileiro de Cerâmica 37904 31 de maio a 4 de junho de 2000 - São Pedro – S.P. RESULTS AND DISCUSION Effect of the amount of dispersant on the rheological properties The isoelectric point (iep) of alumina used has been determined to be at pH near 9 (6) . Previous works on the casting behavior of a commercial zircon powder (7,8) showed the electrophoretic mobility measurements as a function of the pH . They reported that the iep was at pH 5 and the zeta potential became strongly negative with further increase in pH. According to this result, the zircon particles had a high negative zeta potential in the basic pH range. Thus, at pH close to 9, an electrostatic attraction between the neutral alumina particle and the high negatively charged zircon particle can occur. Figure 1 shows the flow curves of the aqueous 48 vol% suspensions of: the stoichiometric, with a 6 wt% excess of alumina, and with a 10 wt% of zircon excess powder mixtures for different amounts of polyacrylate added. Both shear stress and apparent viscosity which is the shear stress to shear rate ratio at any shear rate decreased to a minimum and then gradually increased with increasing the amount of dispersant added. For these suspensions, the maximum degree of dispersion of the particles is achieved when the suspension contained a 0.220.24 wt/wt % of dispersant that produced a minimum of viscosity. All the suspensions having a minimum viscosity showed a Newtonian behavior. Like others anionic polyelectrolytes, adsorption of polyacrylate on the powder surface increases the negative surface charge resulting in a strongly repulsive double layer force and produces, in addition, some steric repulsion that overcome the van der Waal’s attraction. Then, polyacrylate adsorption on both powders in the basic pH range, generated high negative zeta potentials and therefore, electrostatic interaction between zircon and alumina particles changed to repulsive at pH 9. Then, a minimum in viscosity was obtained as the particles had a high surface charge at low electrolyte concentration (high zeta potential). Anais do 44º Congresso Brasileiro de Cerâmica 37905 31 de maio a 4 de junho de 2000 - São Pedro – S.P. 30 S h e a r s t re s s , P a 25 1.2 20 0.97 15 0.13 0.65 10 0.49 0.22-0.36 5 0 0 100 200 300 400 500 600 Shear rate, s-1 a 30 0.13 S h e a r s t re s s , P a 25 1.2 20 0.97 15 0.65 0.49 10 0.24 5 0 0 100 200 300 400 500 600 Shear rate, s-1 b 30 0.065 S h e a r s t re s s , P a 25 1.2 20 0.97 15 0.65 0.13 10 0.22 5 0 0 100 200 300 400 500 600 Shear rate, s-1 c Figure 1: Shear stress vs. shear rate curves for alumina-zircon suspensions (48 vol%) with different content (wt/wt %) of dispersant. a: stoichiometric, b: with a 6 wt% excess of alumina, c: with a 10 wt% of zircon excess powder mixtures. Anais do 44º Congresso Brasileiro de Cerâmica 37906 31 de maio a 4 de junho de 2000 - São Pedro – S.P. High apparent viscosities and non Newtonian behavior were obtained at lower polyacrylate concentrations. The flow behavior changed to shear thinning or plastic depending on the powder composition. Flow curves exhibited a slight hysteresis loop indicating that the suspension was not fully deflocculated. This may be explained by an insufficient adsorption of polyacrylate anion (mainly on the alumina surface) due to low amount of available dispersant. Incomplete adsorption decreased the net negative charge of the mixed powders and consequently repulsion was low. Moreover, heterocoagulation between the uncoated alumina and zircon particles produced a significant increase in viscosity. As the shear rate increased, the breakdown of the flocs released some immobilized liquid increasing the volume of free liquid and consequently the suspension viscosity decreased. For additions higher than 0.65 wt% the apparent viscosity and the shear thinning behavior gradually increased probably due to the presence of an excess of polyelectrolyte in solution. The differences between the three compositions studied were small. Suspensions of the three alumina-zircon mixtures at pH 9.1-9.2 containing 0.22-0.24 wt% of polyacrylate showed a minimum viscosity. The composition with the zircon excess in the mixture had the lower viscosity values. The viscosity of the suspension decreased close to the minimum by addition of 0.13 wt% of dispersant due to low specific surface area of this mixture. The minimum viscosity were obtained at lower dispersant concentration than for the other compositions. At low polyelectrolyte concentration, the suspension of the mixture which contained the highest amount of alumina showed higher viscosity values than the ones of the other compositions due to its higher surface area. Also, higher the content of alumina in the mixture, lower zeta potential value of the powders. This fact was because of negative surface charge of the uncoated alumina powder at pH near 9.2 was lower than the one of the zircon. Therefore, the electrostatic repulsion decreased. For polyacrylate concentrations higher than 0.65 wt%, the viscosity of all the alumina/zircon ratio mixtures increased to similar values. Flow curves were fitted with the Casson model: Anais do 44º Congresso Brasileiro de Cerâmica 37907 31 de maio a 4 de junho de 2000 - São Pedro – S.P. 1/2= c 1/2+ (c D)1/2 where is the shear stress [Pa], D is the shear rate [s -1] and c and c are the Casson yield stress and viscosity parameters, respectively. Except for the suspensions with 0.13 wt% of dispersant which showed a slight time dependency, the Casson model showed a good fit of the experimental data. Figure 2 shows the viscosity and yield stress (Casson model parameters that fit best flow curves of Fig 1 a, b, c) as a function of the dispersant content. Casson viscosity remained unchanged whereas yield stress Casson parameter decreased to a minimum and then increased with increasing the amount of dispersant added. Guo et al.(9) related a c parameter with the magnitude of the attractive interparticle interactions, thus a high c parameter indicates strongly attractive interactions whereas c increases with increasing solid volume concentration. The large variation in the yield stress Casson parameter (Figure 2b) indicated that there was significant differences in the network structure of the suspensions as a result of strong changes in the repulsion between particles which is a function the added amount of dispersant. C a s s o n v is c o s it y , P a s 0.1 0.08 0.06 0.04 0.02 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 Dispersant added , wt% a Anais do 44º Congresso Brasileiro de Cerâmica 37908 31 de maio a 4 de junho de 2000 - São Pedro – S.P. C a s s o n y ie ld s t re s s , P a 4 3 2 1 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 Dispersant added , wt% b Figure 2: a: viscosity, b: yield stress Casson model parameters (best fit of flow curves of Figure 1 a, b, and c) as a function of the dispersant content for alumina-zircon suspensions of: stoichiometric, with a 6 wt% excess of alumina and with a 10 wt% of zircon excess powder mixtures. Effect of the rheological parameters on the density of green cast Figure 3 and 4 show the relative density of green compacts obtained from 48 vol% suspensions of the three compositions studied by slip casting and pressure filtration, respectively as a function of the yield stress Casson parameter. D rie d d e n s it y , g / c m 3 3.2 3 2.8 2.6 2.4 0 0.5 1 1.5 2 2.5 3 Casson yield stress, Pa 3.5 4 Anais do 44º Congresso Brasileiro de Cerâmica 37909 31 de maio a 4 de junho de 2000 - São Pedro – S.P. Figure 3: Relative density of green compacts prepared from 48 vol% suspensions of: stoichiometric, with a 6 wt% excess of alumina and with a 10 wt% of zircon excess powder mixtures by slip casting. Density was nearly constant up to a certain c value and then decreased with increasing c. Compacts resulting from well dispersed Newtonian suspensions or with low c parameter in which repulsion between particles was comparatively large (at a constant Casson viscosity) give compacts with the highest green density. Relative density values of 69.9, 70.3, 71 and 70.4, 70.7, 72 % were found for green compacts prepared by slip casting and pressure filtration, respectively. A high c parameter indicating strongly attractive interparticle interactions was related to low electrostatic repulsion due to insufficient adsorption of polyacrylate. Previous studies on alumina (10) showed that, the network that result from a strongly attractive interactions resisted consolidation and, although it was compressible, a poor packing density was obtained. For suspensions with large excess of dispersant in solution, intermediate c values were obtained. Due to reduced electrostatic repulsion between particles the influence of van der Waals attraction became dominant but density values were close to those from well deflocculated suspension. These suspensions were weakly flocculated as they exhibited higher viscosity than the minimum but smaller c and lower shear thinning character than those resulting from high attractive forces. Weakly flocculated suspensions showed a different packing behavior. As the strength of these network are lower than that formed by high attractive interactions a comparative high density can be obtained added. (10). A decrease of 3% in density was found when 1.2% of dispersant was Anais do 44º Congresso Brasileiro de Cerâmica 37910 31 de maio a 4 de junho de 2000 - São Pedro – S.P. D rie d d e n s it y , g / c m 3 3.2 3 2.8 2.6 2.4 0 0.5 1 1.5 2 2.5 3 3.5 4 Casson y ield stress, Pa Figure 4: Relative density of green compacts prepared from 48 vol% suspensions of: stoichiometric, with a 6 wt% excess of alumina and with a 10 wt% of zircon excess powder mixtures by pressure filtration. Figures 3 and 4 show that compacts prepared from the zircon excess composition showed a maximum in density that is reached at a c value somewhat higher than that corresponding to the other compositions. Since this powder contained a higher proportion of coarse and dense zircon particles, weakly flocculation may be favorable. Slight higher viscosity at low shear rates prevent settling of zircon particles and segregation of components may be reduced if it took place. CONCLUSIONS Rheological properties of aqueous suspensions (48 vol%) of zircon-alumina mixtures containing different amounts of polyacrylate based dispersant were studied. At low dispersant concentrations the viscosity was dependent on the shear rate and time. These characteristics were attenuated with increasing the amount of dispersant added and then gradually increased. The composition with an excess of zircon in the mixture had the lower viscosity values and the amount of dispersant required to reach the minimum viscosity decreased. Flow curves fitted satisfactorily to the Casson model. The Casson viscosity values remained nearly constant whereas the Casson yield stress parameter showed a similar Anais do 44º Congresso Brasileiro de Cerâmica 37911 31 de maio a 4 de junho de 2000 - São Pedro – S.P. behavior to that observed for the apparent viscosity variation with increasing the dispersant concentration. Compacts resulting from suspension in which repulsion between particles was comparatively large showing low yield stress Casson parameter (at a constant Casson viscosity) gave compacts with the highest green density. Maximum relative density values of 69.9, 70.3, 71 and 70.4, 70.7, 72 % were found for green compacts resulting from well deflocculated suspensions by slip casting and pressure filtration, respectively. These values were obtained using 0.24 to 0.49 wt% of dispersant concentration. REFERENCES 1. N. Kapuri; K.N. Ray; G.S. Updhyaya, Interceram 45, 6 (1996) 427. 2. P. Descamps, S. Sakaguchi, M. Pooterman, F. Cambier, J. Am. Ceram Soc. 74, 10 (1991) 2476. 3. J. Mewis , Rheology of suspensions in : Rheology, Astarita G. et al eds. Plenum. NY, vol 1, 149 (1980). 4. H. A. Barnes, J.F. Hutton, K. Walters, An introduction to rheology, Elsevier Sci Publishers, Amsterdam, 116 (1989). 5. L. Bergström, Rheology of concentrated suspensions in : Surface and colloid chemistry in advanced ceramic processing, R.J. Pugh and L. Bergström eds., Marcel Dekker, NY ,193-244(1994). 6. P.A. Smith, R.A. Haber, J. Am. Ceram. Soc. 78, 7 (1995) 1737. 7. R. Moreno, J.S. Moya, J. Requena in: Taylor D. (Ed. ), Science of Ceramics, vol.14, The Institute of Ceramics, Stoke-on Trent, UK (1988), pp. 849-853. 8. R. Moreno, J.S. Moya, J. Requena, Ceramic International 17,1 ( 1991) 37. 9. L. Guo, Y. Zhang, N. Uchida, K. Uematsu, J. Am. Ceram. Soc. 81, 3 (1998) 549. Anais do 44º Congresso Brasileiro de Cerâmica 37912 31 de maio a 4 de junho de 2000 - São Pedro – S.P. 10. L. Bergström, Ch.H. Schilling, I.A. Aksay, J. Am. Ceram. Soc. 75, 12 (1992) 3305.