Artigo Completo - Clique Aqui

advertisement

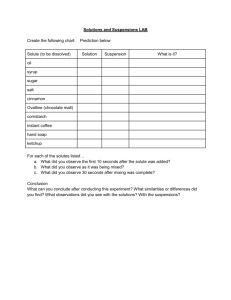

Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 36801 SLIP PROPERTIES AND PRESSURE FILTRATION OF ALUMINA. L.B. Garrido CETMIC (Centro de Tecnología de Recursos Minerales y Cerámica). Cno. Centenario y 506. C.C.49 (1897) M.B. Gonnet. Prov. de Buenos Aires. ARGENTINA. FAX:54- 221-4710075. E-mail:garridol@netverk.com.ar ABSTRACT Pressure filtration of oxide and advanced ceramic materials has recieved a great attention in recent years. In this work, the results of a pressure filtration experiments using aqueous alumina suspensions (A-16SG, Alcoa Inc., USA) up to 50 vol% solid concentration are presented. Concentrated suspensions of different degree of dispersion were prepared to study the effect of the applied pressure on the relative density ( % of the theorical) of dried compacts obtained at 4 to 20 MPa. Slip properties were evaluated by rheological measurements and correlated with the characteristics of the compacts. Key words: Alumina, pressure filtration, rheological properties. INTRODUCTION Highly loaded and stable suspensions are used to produce green ceramic bodies that showed high density and homogeneous and fine microestructures. However, previous studies reported that low viscosity suspensions provided low filtration rates and same mass segreggation during the consolidation step of ceramic multicomponent. To overcome these problems either solid concentration is usually increased or surface potentials between particles can be controlled or manipulated to produce a high density consolidates. This is the case of concentrated suspensions in a flocculated or Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. coagulated state (1) 36802 . Thus, optimization of the slip properties is required for suitable control of the casting process. In this work, results of pressure filtration experiments using concentrated aqueous alumina suspensions up to 20 MPa are presented. The effect of solid volume concentration, state of dispersion and the desaggregation method on the relative density of alumina green compacts is studied. MATERIALS AND METHODS Materials. Alumina powder used is a fine and pure -Al2O3 (A-16 SG, Alcoa Inc., USA) and contains Na2O and MgO as main impurities (2,3). The mean particle size determined was 0.4 m and the specific surface area 9.5 m 2/g (4) The isoelectric point has been determined to be 9 (4) . Suspension preparation and characterization. Dispersed 20-50 vol% suspensions were prepared by adding the powder to aqueous solutions containing HCl or the dispersant. The suspensions were ultrasonicated for 25 min. The state of dispersion was varied using the procedure described elsewhere(1) . Dispersed 20 vol% were flocculated by changing the pH to 9 or coagulated by 1.8 M NH4OH. Dispersed suspensions containing 50 vol % solid concentration were prepared by attrition milling to compare the effect of the desaggregation method on the compact characteristics. Flow curves of the suspensions were obtained using a rotational viscometer Haake RV3 of coaxial cylinders with NV and MVIP measure systems at 25°C. Pressure filtration and characterization of the compact. Pressure filtration was done on a metallic sintered porous filter with a wet filter paper placed on it. The pressure was applied from the top and the liquid moved through the porous filter. Pressure was manually controlled until no change in the pressure indication was observed and kept at a constant value for a minimum of 25 min. Cylindrical compacts were dried 24 hs at room temperature and then at 110 C for 24 hs. Relative density (% of the theorical) was measured by Hg inmersion. Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 36803 Particle size distribution was used to examine the tendency of the particles to segregate. Some selected compacts dried at room temperature were sliced in three parts. Various grames of solid were resuspended at pH=4 at a solid concentration adequate for Sedigraph analysis. RESULTS AND DISCUSSION Figure 1 shows the relative density (% of the theorical) as a function of the applied pressure for green compacts obtained from 20 vol% alumina suspensions deflocculated R e la tiv e d e n s ity ,% th e o r ic a l (pH=4), flocculated (pH=9) and coagulated with 1.8 M NH4OH. 70 65 60 55 50 0 5 10 15 20 Applied pressure, MPa pH=4 pH=9 coagulated Figure 1: Relative density of green compacts obtained from alumina suspensions with different degree of dispersion vs applied pressure. Density is dependent of the applied pressure for coagulated and flocculated suspensions. At 16 MPa the maximum density is reached for the unstable suspensions. In pressure filtration the suspension is subjected to a compressive stress. Previous studies reported that strongly attractive interactions resulted in a particle network that supported some stress up to a critical value. Once this critical stress value was exceded the network consolidated to a higher volume fraction with a higher critical stress. Figure 2 shows the flow curves for alumina suspensions (20 vol %) with different degree of dispersion. Low viscosity suspension of Newtonian flow behaviour was obtained at pH=4 where the particle had a high surface charge at low electrolyte concentration (high zeta potential). 36804 Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. At high electrolyte concentration, zeta potential decreased due to double layer compression and particles adhered weakly as attraction was significative.This adhesion is potentially reversible. Hence, the suspension showed a typical shear thinning behaviour of coagulated suspensions. 120 pH=9 S h e a r s tr e s s , P a 100 80 60 40 coagulated 20 pH=4 0 0 100 200 300 400 500 600 Shear rate, s-1 Figure 2: Shear stress vs shear rate curves for alumina suspensions (20 vol%) with different degree of dispersion. An strong atractive potential is obtained by changing the pH to 9 due to the reduction of the charge of alumina particle and produced a flocculated suspension. The flow curve exhibited high shear stress values and a hysteresis loop between the two branches of the flow curve that are related with the formation of unstable structures. The liquid is immobilized in the flocs resulting in a higher effective solid content and therefore the viscosity was higher than the one of the deflocculated suspension. Shear thinning of unstable suspensions was attributed to the break down of the agglomerates and the release of the inmobilized liquid. Flow curves were fitted with the Casson model: 1/2= c 1/2+ ( c D)1/2 where is the shear stress [Pa], D is the shear rate [s -1] and c and Casson yield stress and viscosity respectively. In agreement with Guo et al. c indicates strong flocculation whereas low c shows low solid content. c are the (5) a high Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 36805 Tabla 1:Viscosity and yield stress Casson model parameters (best fit of flow curves of Fig 2 and 4) Suspension Viscosity yield stress Correlation mPas mPa 0 Coeficient Defl., pH=4, 20% 1.539 0.985 Coagulated 3.9 8095 0.920 Flocculated, pH=9 13.75 60410 0.987 Defl., pH=4, 27% 2.544 43.8 0.986 Defl., pH=4, 36% 4.751 216 0.987 Defl., pH=4, 50% 22.72 8367 0.998 Density behaviour correlated well with slip properties (viscosity and yield stress Casson parameters). Dispersed suspensions of low viscosity and small yield stress could be packed to a higher density compact than the unstable suspensions. Futhermore, the effect of the degree of dispersion on the density was similar to that previously reported (1). Figure 3 shows relative density of green compacts obtained from alumina suspensions deflocculated (pH=4) for solid volume concentrations up to 50 vol% as a function of the applied pressure. Green densities of the compacts were nearly constant with the applied pressure. Values close to 64 % at 8 MPa were obtained with increasing solid concentration from 20 to 37 vol%. A decrease of 3% was obtained with the 50 vol% suspension. No deformation or cracking was observed after drying. 36806 R e la tiv e d e n s ity ,% th e o r ic a l Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 70 65 60 55 50 0 5 10 15 20 Applied pressure, MPa 20 v ol% 27 v ol% 37 v ol% 50 v ol% Figure 3: Relative density of green compacts obtained from deflocculated at pH=4 alumina suspensions with different solid volume concentrations vs applied pressure. 40 S h e a r s tr e s s , P a 50 30 20 10 37 26 20 0 0 100 200 300 400 500 600 Shear rate, s-1 Figure 4: Shear stress vs shear rate curves for alumina suspensions with different solid concentration ( vol%). Figure 4 shows the flow curves of alumina suspensions with different solid volume concentration. The apparent viscosity at 500 s-1 of suspensions increased from 8 to 79 mPas with increasing solids content from 37 to 50 vol%. The concentration of HCl in solution required to electrostatically stabilize the suspension increased from 0.04, 0.1, to 0.2 M for solid volume concentrations of 20, 37 and 50 % respectively. An increase in the concentration of counterions (high ionic strength of the solution) decreased the zeta potential and consequently increased the viscosity of the suspension. Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 36807 Shear thinning behaviour was observed for suspensions containing more than 20 vol% of alumina. Shear thinning of stable concentrated suspensions was previously attributed to the perturbation of the suspension structure at rest by the viscous forces at high shear rates. The Casson model showed a good fit of the flow curves (Table 1). Pressure filtration of high solid content suspension of low viscosity give compacts with the highest green density. Green densities decreased as the viscosity and yield stress Casson parameters increased . Compacts prepared from atrittion milled 50 vol% suspensions (pH=4) showed poor characteristics than the obtained by ultrasonication. Lower densities and deformation after demoulding were found. Significative differences occurred in the particle size diistribution curves of the powders. A decrease in the content of fine particles was seen from the top to the bottom of the compact with respect to the distribution of the ultrasonicated alumina. The mean diameter d 50 increased from 0.38, 0.4 and 0.46 m to 0.42, 0.5 and 0.7m for the top to the bottom. Higher d 50 than 0.4m for the milled suspension was due to a decrease in efficiency of the attrition as the viscosity of the suspension increased. Stabilized suspensions containing high amount of agglomerate particles (not completely desaggregated prior to the pressure filtration experiment) were loosely packed at the bottom of the compact where the content of coarse particles was high. As expected, at high solid concentration deflocculated suspensions of coarse particles showed a strong dilatant behaviour. Dispersed 50 vol% suspensions were dificcult to prepared with HCl and the effects of adding a polyelectrolyte (ammonium polyacrylate AP) and citric acid AC to achieve stability by an electrosteric stabilizing mechanism were examined. Figure 5 shows the relative density of green compacts prepared from 50 vol % deflocculated suspensions at pH=4 and with different amounts of dispersants for applied pressures up to 20 MPa. Comparison of green density values with those obtained from electrostatically stabilized suspension showed that the use of CA was more effective. The additon of AP caused a small effect on the density. 36808 R e la tiv e d e n s ity ,% T h e o r ic a l Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 70 65 60 55 50 0 5 10 15 20 Applied pressure, MPa pH=4 0.5%AP 0.44%AP 0.3%CA Figure 5: Relative density of green compacts obtained from 50 vol% suspensions at pH=4 and deflocculated with 0.44-0.5 wt% of ammonium polyacrylate and 0.3 wt% citric acid vs applied pressure. Figure 6 shows the shear stress vs shear rate curves for 50 vol% suspensions with deflocculant. pH=4 40 S h e a r s tr e s s , P a 0.5%AP 30 0.4%AP 20 0.3%CA 10 0 0 100 200 300 400 500 600 Shear rate, s-1 Figure 6: Shear stress vs shear rate curves for 50 vol % alumina suspensions with different dispersant. The addition of 0.44 wt% of AP slightly improved the degree of dispersion of the particles as lower apparent viscosity values (63 mPas at 500 s -1) than the ones of the suspension deflocculated with HCl ( 80 mPas) were obtained. The flow curve exhibited a hysteresis loop indicating that the suspension was not fully deflocculated. Further Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 36809 additions of AP increased the apparent viscosity to 77 mPas probably due to the presence of an excess of polyelectrolyte. At pH=9.45 (above iep pH ) the surface developed AlO- groups which enhanced electrostatic repulsion between the alumina surface and the polyelectrolyte. Then, low adsorption of polyacrylate anion on the alumina surface groups and consequently a higher amount of free polyelectrolyte produced a decrease in the degree of dispersion. Low viscosity suspension of shear thinning behaviour was obtained with 0.3 wt % of citric acid (pH=8). At pH 8 more Al OH2+ groups existed on the alumina surface that increased the COO- adsorption and improved the degree of dispersion. Hibder et al. (6) proposed that citrate stabilized alumina suspensions by a combined electrostatic and steric mechanism at very small interparticle separations. Green density values of 65 % were obtained by pressure filtration 50 vol % slip with viscosity of 29 mPas. Salomoni et al.(7) reported densities of green bodies cast at 3.4 MPa of 65.2%. CONCLUSIONS Low viscosity suspensions with a small yield stress due to greater repulsive interparticle potentials and an optimum particle size distribution produced green compacts with the highest relative density. Green densities decreased as the viscosity and yield stress Casson parameters increased . Compacts obtained from stabilized suspensions containing high amount of agglomerate particles (not completely desaggregated prior to the pressure filtration experiment) were loosely packed at the bottom where the content of coarse particles was high as indicated by the particle size distribution measurements. Some of them did not retain their initial shape after demoulding. Compacts resulting from weakly and strongly flocculated suspensions were less dense and the relative density increased with increasing the applied pressure. Anais do 43º Congresso Brasileiro de Cerâmica 2 a 5 de junho de 1999 - Florianópolis – S.C. 36810 REFERENCES (1) J.C. Chang, B.V. Velamakanni, F.F. Lange, D.S. Pearson, J. Am. Ceram. Soc. 74, 9 (1991) 2201. (2) C.M. Incorvati, D.H. Lee, J.S. Reed, R.A. Condrate, Am. Ceram. Soc. Bull. 76, 9 (1997) 65. (3)J.F. Kelso, J.A. Ferrazolli, J. Am. Ceram. Soc. 72, 4 (1989) 625. (4) P.A. Smith, R.A. Haber, J. Am. Ceram. Soc. 78, 7 (1995) 1737. (5)L. Guo, Y. Zhang, N. Uchida, K. Uematsu, J. Am. Ceram. Soc. 81, 3 (1998) 549. (6) P.C. Hibder, T.J. Graule, L.J. Gauckler, J. Am. Ceram. Soc. 79, 7 (1996) 1857. (7)A. Salomoni, C. Galassi, E. Roncari, J. Stamenovik, Fourth Euro Ceramic, Ed. C. Galassi. Gruppo Editoriale Faenza Editrice S.p.A, Italia (1995) ,Vol.I, p453.