Polyurethane - University of Nebraska Omaha

Polyurethanes

History of Polyurethanes:

Polyurethane Chemists

• Dr. Otto Von Bayer

(1937)

– IG Farben Industries

• Rigid and flexible foams

• TDI and polyols

– Attempts to reduce natural rubber use

History of Polyurethanes:

Polyurethane Chemists

• Adolf Wurtz (1848)

• Karl-Heinz Hentschel (1884)

– Phosgenation of amines

Isocyanate Monomer Synthesis

• Dr. Otto Bayer (1937)

– First diisocyante synthesis

• Toluene Diisocyanate Synthesis (TDI)

– Reaction creates 80/20 mixture of 2,4-TDI and 2,6-TDI

Isocyanate Monomer Synthesis

• Diphenylmethane Diisocyanate (MDI) Synthesis

– Attempt to find less toxic monomer for PU reactions

– MDI chemistry is more complex

• Allows for more specific applications

Imperial Chemical Industries

• ICI and WWII applications of isocyanates

– Barrage balloons

• Used MDI as cross-linking agent

– Resistant to hydrogen

– Applications also included rigid foams in planes

• War applications soon faded

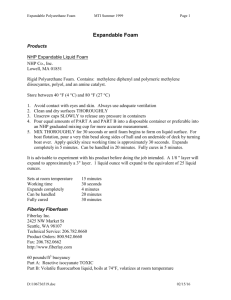

• Isocyanates and water

• Carbon dioxide is side product

• Initially a defect it was turned into an application as foam

• ICI takes notes from Bayer AG

– Designs a machine outside of the Germans patented machine

Imperial Chemical Industries

• Toxicity of TDI (1950s)

– Led to design of MDI/polyester systems

• Portable refrigerators, domestic chambers of ships, chemical plan insulation

• Further improvements with CFC’s

– CFC blowing agents created superior insulating foams

• Thin walled refrigerators create interest rigid PU foams around the world

Polyurethanes

• Polyurethanes are much more than just foam

• PU’s can be

– Elastomers

– Paints

– Adhesives

– Fibers

• Spandex

Breakdown of the PU Industry

Figure from Essentials

Chemical Industry on

University of York website

Economics

• The PU industry was estimated to produce

13.65 million tons of plastic in 2010 and is expected to grow to 17.95 million tons by

2016

• The PU industry is expected to grow from $33 billion in 2010 to $55.5 billion in 2016

• North America, Asia-Pacific, and Europe account for 95% of the PU market

Numbers found from source 6

Polyurethane Structure

Carbamate bonds created by isocyanates reacting with hydroxy groups of a polyol

Polyurethane Reactions

• Tertiary amines catalyze the reactions

• Isocyanate groups react with polyols

Polyurethane Monomers

• Polyurethanes consist of different block co-polymers

• MDI- 4 4'-diphenylmethane diisocyanate

• TDI- Toluene-2,4-diisocyanate

Polyurethane Monomers

Polyols- hydroxy terminated polyether, polyester, polyolefins, and glycols

Polyurethane:

Block Copolymers

• Soft block/hard block microphases

-Poly(1,4-butylene adipate) is part of the soft block microphase

-Soft blocks have 600-3000 MW and T g below room temperature

-The soft block cross-link interaction with the hard block gives rise to the rubbery nature of these elastomers

-The hard block consists of TDI or MDI

-Higher density of phenyl rings and urethane links cause hardness

Figures from source 7

Soft/Hard Block H-Bonding

Interactions

Importance of Polyol choice

Figures from source 7

Polyurethane Reactions

• Multiple types of reactions make up different end products of polyurethanes

• Polyurea reactions are important for spandex production

Which sometimes can be a bad thing!

• Someone needs to introduce this guy to pants and suspenders!

• Suspenders are made of polyesters

– Dr. Tisko should tell this guy how awesome suspenders are

Bibliography

1.

http://www.pslc.ws/macrog/urethane.htm

2.

http://www.8linx.com/cnc/polyurethane_foam.htm

3.

http://www.essentialchemicalindustry.org/polymers/polyurethane.html

4.

http://sunilbhangale.tripod.com/pu.html

5.

http://www.poliuretanos.com.br/Ingles/Chapter1/132comercial.htm

6.

http://www.plastemart.com/Plastic-Technical-

Article.asp?LiteratureID=1674&Paper=global-polyurethane-market-PU-foamsthermoplastic-elastomers

7. J.M. Buist. Developments In Polyurethane-1; Applied Science Publishers LTD, UK,

1978.