CostaRicaphase2report

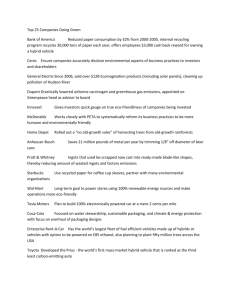

advertisement