CONCEPT FOR DISCUSSION ONLY

advertisement

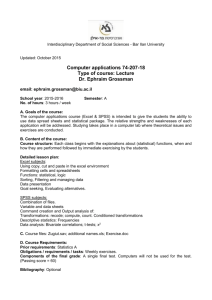

MMT global setup plan 1.1, 8 pages. NPT -241 – TAIZ CURRICULUM DEVELOPMENT PROJECT Global setup plan Materials & Manufacturing Technology*) version 1.2 20091003 Name of programme/course Master of Engineering & Management, course Materials & Manufacturing Technology. *) In close consideration with my academic supervisor the name of the course has been changed from Materials Processing into Materials & Manufacturing Technology, since this name is – from my point of view – more clear and covers the content and goals of the course better. I think that the knowledge and understanding of the structure and properties of materials have to be a goal in itself and not only for the benefit of the understanding of manufacturing processes. In developing countries all basic materials (e.g. steel rods for concrete reinforcement) and almost all metal and plastic products are imported, so it is really important that the local engineering staff has sufficient knowledge, understanding and skills to evaluate the quality of materials and to test whether materials meet their specification. Learning objectives 1. Knowledge and understanding of the structure and properties of materials, in particular engineering materials like metals, ceramics, polymers and composites. 2. Understanding and skills to evaluate the quality of engineering materials and to test whether materials meet their specification. 3. Knowledge and understanding of the most important manufacturing processes for basic metals and products of engineering materials. 4. Understanding of the relationships among the material properties and the process parameters of manufacturing processes. 5. Knowledge, understanding and skills to make quantitative analyses of manufacturing processes. 6. Knowledge, understanding and skills to select the most appropriate manufacturing process for the production of any product or product part, depending on the product shape, product dimensions, product tolerances and batch size. 7. Knowledge and understanding of product design considerations related to manufacturing processes. Summarizing: The main objective of the course is to acquire sufficient knowledge, understanding and skills about the best way to manufacture any product or part of a product from engineering materials or to answer for existing products the question ‘How it’s made?’. Course schedule and topics per day The didactical concept of the course is based on a balanced mix of lectures, group discussions and an immediate application of the knowledge from the courses by solving problems and working on case studies. By working on more complicated problems and case studies students have to work together in teams; the number of students in a working team will be directly related to the complexity of the problem definition. 1 MMT global setup plan 1.1, 8 pages. Student participation in the working teams and group discussions belongs to the assessment format of the student. A daily teaching and learning module (four hours) consists of the following activities: 1. A theoretical introduction of the relevant fundamentals, concepts, methods, processes and techniques by the lecturer. 2. A direct link to the industrial practice, showing product examples and one or two short video films; incidentally a guest speaker from a Yemen company will be invited. 3. A group discussion about some topics directly related to the given lecture or some reflection issues. 4. Applying the knowledge of the module by solving problems (exercises) and working on case studies in student teams. The results of the case studies have to be presented for the lecturer and other students. Schedule Topics per module Day 1 Introduction: Learning objectives. Course info. Examination requirements. What is manufacturing? Materials in manufacturing. Manufacturing processes. Production systems. Product attributes (dimensions, tolerances, surfaces). Interfaces with other courses of the programme. Day 2 Material properties: Atomic structure and the elements. Bonding between atoms and molecules. Crystalline and non-crystalline structures. Engineering materials. Stress-strain relationships. Hardness. Effect of temperature on properties. Fluid properties. Visco-elastic behaviour of polymers. Some physical properties. Day 3 Engineering materials: Metal alloys. Ferrous metals. Nonferrous metals. Fundamentals of polymer science and technology. Thermoplastic polymers. Thermosetting polymers. Elastomers. Short introduction to ceramics. Introduction to composite materials. Day 4 Processes for shapeless metal materials (liquid and powder): Fundamentals of casting: heating, pouring, solidification and cooling. Metal casting processes, expendable-mould casting, like sand casting, and permanentmould casting processes. Casting quality. Metals for casting. Product design considerations. Essentials of powder metallurgy. Some rapid prototyping technologies. Day 5 Shaping processes for plastics, rubber and composites: Properties of polymer melts. Extrusion. Production of sheet and film. Fibre and filament production. Coating processes. Injection moulding. Compression moulding. Blow and rotational moulding. Thermoforming. Polymer foam processing. Product design considerations. Rubber processing and shaping. Processes for polymer composites, open and closed mould processes, filament winding and pultrusion. Day 6 Metal forming (bulk deformation): Material behaviour in metal forming. Temperature in metal forming. Strain rate sensitivity. Friction and lubrication in metal forming. Rolling and rolling related processes. Forging and forging related processes. Extrusion. Wire and bar drawing. Day 7 Sheet metalworking: Cutting operations. Bending operations. Drawing. Other sheet-metal forming operations. Dies and presses for sheet-metal processes. Sheet-metal operations not performed on presses. Bending of tube stock. 2 MMT global setup plan 1.1, 8 pages. Day 7 (Cont.) Day 8 Day 9 Day 10 Day 11 Day 12 Property enhancing and surface processing operations: Short introduction on heat treatment of metals, cleaning and surface treatments, coating and deposition processes. Material removal processes: Chip formation in metal machining. Force, power and energy relationships in machining. Cutting temperature. Turning and related operations. Drilling and related operations. Milling. Machining centres and turning centres. Other machining operations. High-speed machining. Material removal processes: Tool life. Tool materials. Tool geometry. Cutting fluids. Machinability. Tolerances and surface finish. Selection of cutting conditions. Product design considerations. Grinding and related abrasive processes. Non-traditional machining. Electric discharge processes. Laser beam machining. Joining and assembly processes: Fundamentals of welding. Features of a fusion-welded joint. Welding processes, arc welding, resistance welding, oxyfuel gas welding and other fusion-welding processes, solid-state welding. Weld quality. Weldability. Design considerations in welding. Brazing. Soldering. Adhesive bonding. Fastening methods in mechanical assembly. Design considerations in assembly. Manufacturing systems and manufacturing support systems: Numerical control. Industrial robots. Group technology. Flexible manufacturing systems. Production lines. Quality control. Metrology. Inspection principles. Conventional measuring instruments and gages. Measurement of surfaces. Advanced measurement and inspection technologies. Summary: Overall overview. Guidelines and recommendations. Material and manufacturing process selection related to the product function, product shape, product dimensions, product tolerances, batch size and costs. Last consultancy. The content of the course will be highlighted on the basis of product examples, problems, websites, cases, films, reflection issues, etc. Proposed textbook Fundamentals of Modern Manufacturing: Materials, Processes and Systems, 3rd edition, 2007. Mikell P. Groover, Professor of industrial and systems engineering, Lehigh University (USA) ISBN: 978-0-471-74485-6. See http://he-cda.wiley.com/WileyCDA/HigherEdTitle/productCd-0471744859,courseCdE43600,pageType-copy,page-collegeAbout.html This book is the primary mandatory textbook for the course. It is a well established textbook that presents almost all manufacturing processes for engineering materials from a theoretical and practical point of view, including the required background information about the nature and properties of materials. For the work on case studies some more detailed books are available in the library. Assessment format The assessment will be done for 30% based on the student participation in group discussions and in the student teams working on case studies and solving course related problems. 3 MMT global setup plan 1.1, 8 pages. Due to the broad scope of the field, it is practically impossible to define appropriate items for a final assignment, which cover a significant part of the course content. For that reason the 70% for the final assessment have to be done as a written examination. If the number of participants is relatively low the written examination can be replaced by an oral examination. Planning and milestone deliverables Activity Overall preparation, selection of books, video films sources, etc. Indication of the level of detail of the course development result Preparation of day 1 Preparation of day 2 Preparation of day 3 Preparation of day 4 Preparation of day 5 Preparation of day 6 Preparation of day 7 Preparation of day 8 Preparation of day 9 Preparation of day 10 Preparation of day 11 Preparation of day 12 Expected time duration days 1 Deliverables 2 2 2 2 2 2 2 2 2 2 2 2 Sheets*), relevant exercises and/or cases day 1 Sheets*), relevant exercises and/or cases day 2 Sheets*), relevant exercises and/or cases day 3 Sheets*), relevant exercises and/or cases day 4 Sheets*), relevant exercises and/or cases day 5 Sheets*), relevant exercises and/or cases day 6 Sheets*), relevant exercises and/or cases day 7 Sheets*), relevant exercises and/or cases day 8 Sheets*), relevant exercises and/or cases day 9 Sheets*), relevant exercises and/or cases day 10 Sheets*), relevant exercises and/or cases day 11 Sheets*), relevant exercises and/or cases day 12 Examination example List of books for the library List of video film sources Student’s guide *) Including photographs of relevant product examples and specification of the chosen video film passages. An expected number of development days Following the deliverables planning a total number of 25 development days is expected. A possible redesign after the first year has to be discussed later. Delivery date The full proposal will be delivered not later than 20100430. Short CV The course development will be done by ir. Hans Ponsen. His CV (including personal data, job history, teaching and other relevant expertise, and publications related to education) has been added as Appendix B. 4 MMT global setup plan 1.1, 8 pages. Appendix A: Course description from EM program Specification document Course Description Taiz EM master Course name Course code Materials processing Lecturer Course language English Course period Block 2 Examination period Credits Course objectives 3 1. Knowledge of engineering materials e.g. metals, ceramics, polymers, composites and their processing technologies. 2. Understanding the relationships among the material properties and the process variables of a manufacturing process. 3. Skills for quantitative analysis of manufacturing processes 4. Knowledge and understanding of product design guidelines Organization of the course Activities: Lectures and student presentations in 10 days. 1 What Is Manufacturing? Materials in Manufacturing. Manufacturing Processes. Production Systems. 2 Material Properties and Product Attributes. 3 Engineering Materials 4 Solidification Processes 5 Particulate Processing of Metals and Ceramics 6 Metal Forming and Sheet Metalworking 7 Material Removal Processes 8 Property Enhancing and Surface Processing Operations 9 Joining and Assembly Processes, Special Processing and Assembly Technologies 10 Manufacturing Systems, Manufacturing Support Systems Course Material Course Book Fundamentals of Modern Manufacturing: Materials, Processes, and Systems, 3rd Edition 5 MMT global setup plan 1.1, 8 pages. Lecture Slides Case study Assignments Example Exam Mikell P. Groover, Professor of Industrial and Systems Engineering, Lehigh University ISBN: 978-0-471-74485-6 ©2007 See http://he-cda.wiley.com/WileyCDA/HigherEdTitle/productCd0471744859,courseCd-E43600,pageType-copy,pagecollegeAbout.html Blackboard Blackboard Blackboard Software tools that are needed Tbs Assessment Type Grading Exercises and final “laboratory”project 30% exercises, 70% final project 6 MMT global setup plan 1.1, 8 pages. Appendix B: Curriculum vitae - Name Address Phone Date of birth Place of birth E-mail address : Johannes Matthijs (Hans) Ponsen : Denekamperdijk 36, 7581 PJ Losser (NL) : 0031 – 53 – 5388435 : 29th of November 1943 : Coevorden (NL) : hansponsen@yahoo.com During my academic education at the Eindhoven University of Technology I obtained a propaedeutic certificate in Chemical Engineering in 1962 and finished my Master in Mechanical Engineering in 1968. My Master thesis was dealing with an analysis of the wire drawing process. My first job at the University of Twente in Enschede (at that time still the Twente Technical High School) I got in 1968 and worked there till 1974. I developed and taught a couple of new courses on manufacturing and forming technology (including laboratory activities) for this young university. Related to research I participated in an international research programme on metal extrusion and was member of the International Cold Forging Group. In the period of 1974 – 1980 I worked in consultancy and engineering services at Raskin Nederland in Laren (N.H.). This small enterprise was – as a daughter company of some important European machine tool manufacturers – specialized in the design and implementation of complete production lines for the sheet metal and forming industries in the Netherlands. In 1980 I made a change to the University of Applied Science in Arnhem (at the time still the HTS Arnhem), where I was teaching till 1987 a couple of courses in the field of manufacturing, design engineering, industrial engineering, materials science and applied mechanics for students in mechanical, electrical and civil engineering. An important task was to intensify the contacts with industry via student internships and thesis projects, but also through consultancy and engineering services (new at that time). In 1987 I have been sent out by the Dutch Government to Curaçao as ‘technical expert’ for the Netherlands Antilles in the field of manufacturing and materials engineering, to support the local industry and the University of the Netherlands Antilles (UNA). I developed there a couple of courses for the small university and for the industry, was involved in the technical upgrading of a couple of companies, supported the setup of two new production plants and made a significant contribution to the quality control process of imported materials. During the period 1987 – 1992 I trained two local counterparts, to take over my job after my departure. Since 1992 I was working at the University of Twente, Department of Engineering Technology, in the Group Design, Production & Management of Prof.dr.ir. F.J.A.M. van Houten. I was intensively involved in the design and implementation of the new project oriented curricula of mechanical engineering (see list of publications), was teaching a couple of manufacturing courses for students in mechanical, industrial and design engineering and developed and managed a large couple of educational projects. Since 1998 I was coordinator of the international Master programme Industrial Design & Manufacturing (IDM), a joint activity of our university with the University of Dortmund (Germany), and later on with the 7 MMT global setup plan 1.1, 8 pages. Aalborg University in Denmark and the University of Strathclyde (Glasgow, Scotland). In addition, I was the representative of the faculty in some international organizations, like SEFI. I have been retired in November 2008, after which I developed again in 2009 a new course on construction elements and taught a manufacturing course for Bachelor students in their last year. I am co-author of the textbook on manufacturing Industriële Productie. I am married, have two married daughters and four grandchildren. My most important hobbies are travelling, walking, cycling and reading. Publications related to education: - - - - - - - - Ponsen J.M., Kals H.J.J. (1996). A project-oriented starter course in manufacturing. Proceedings of the SME International Conference on Manufacturing Education. San Diego (USA), 13-15 March 1996. Ponsen J.M., Kals H.J.J. (1998). Design and manufacturing in a project-oriented curriculum. Proceedings of the SME International Conference on Manufacturing Education. San Diego (USA), 14-16 October 1998. Ponsen J.M., Mesenhöller E. (2000). The development of an international Masters program in Industrial Design & Manufacturing. Proceedings of the 28th SEFI Annual Conference. Paris (France), 6-8 September 2000. Ponsen J.M., Ruijter C.T.A. (2002). Project-oriented education: Learning by doing. Proceedings of the First CIRP International Manufacturing Education Conference: CIMEC-2002. (p 135-144). Enschede (The Netherlands), 3-5 April 2002; ISBN 90-36517346. Ponsen J.M., Houten F.J.A.M. van, Mantel R.J. (2002). An international Masters program in Industrial Design & Manufacturing. Proceedings of the First CIRP International Manufacturing Education Conference: CIMEC-2002. (p 177-186). Enschede (The Netherlands), 3-5 April 2002; ISBN 90-365-17346. Ponsen J.M., Ruijter C.T.A. (2002). Improvements in project-oriented education. Proceedings of the 30th SEFI Annual Conference: The Renaissance Engineer of Tomorrow. Florence (Italy), 8-11 September 2002; ISBN 88-8304-479-7. Ponsen J.M., Belt D. van de (2005). How to realize an internationalization component in engineering curricula. Proceedings of the 33rd SEFI Annual Conference. Ankara (Turkey), 7-10 September 2005. Ponsen J.M. (2007). Study tour projects. Proceedings of the 35th SEFI Annual Conference. Miskolc (Hungary), 1-4 July 2007. 8