Resources_Ting - Stanford University

advertisement

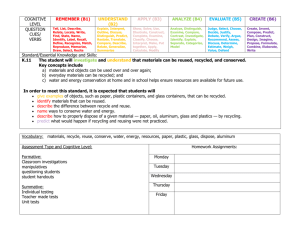

Resources Goal Summary R1 Integrate systems and materials with low environmental impact R2 Minimize the use of non-renewable resources R3 Reuse parts of the existing building R4 Design for durability, adaptability and disassembly R5 Reuse and recycle demolition waste R6 Recycle and compost R1 Integrate systems and materials with low environmental impact Goal Perform lifecycle assessment to compare the environmental burden and embodied energy effects of various assembly materials. Methods and Justification Lifecycle assessment is the most complete and reliable assessment of environmental impacts for materials and resources. To fully evaluate the environmental impact of a new building, lifecycle phases of various assemblies from raw material extraction to disposal must be considered. Green Globes explicitly includes lifecycle assessment as its credit criteria which accounts for 40% of the total resource score, while LEED does not award credit explicitly for lifecycle assessment. In the schematic design stage of the new GSB, there is no explicit lifecycle assessment. However, lifecycle assessment is implicit through, for instance, consideration of material sources and future recycling value. Lifecycle phases include the following: ● ● ● ● ● ● Raw material extraction Production Distribution Installation In-use Disposal Material sources are related to raw material extraction and production, while future recycling value of materials is related to disposal. The intent of the new GSB project is to achieve LEED platinum certification. Without lifecycle assessment, LEED credits could still be pursued. To obtain 40% of Green Globes credits in resources, further efforts need to be made in explicit lifecycle analysis, potentially through computational tools such as the Athena software1 recommended by 1 Athena Institute, EcoCalculator for Assemblies, http://www.athenasmi.ca 1 Green Globes. Examples of material environmental impact evaluations are included in the following four building assemblies. Foundation and floor assembly materials Excavation materials from the existing site will be reused as fill. Stockpile materials also have potential for reuse and recycling2. Wood flooring will be used in large classrooms, while bamboo flooring is also considered as an alternative3. Bamboo is a more rapidly renewable resource compared to wood. Carpet backing material will also have a high recycled content. Structural systems and walls Cast-in-place reinforced concrete will be used for the parking structure and library. Concrete has high carbon emission. To minimize the environmental impact of concrete, high volume flyash is recommended by the Sustainability Task Force 4. Flyash also increases the strength of concrete and reduces corrosion of reinforcing steel, which results in a longer lifespan of reinforced concrete. Steel frame will be the main structural form for the above grade buildings. Structural back-up for stone veneer will be accomplished with steel stud systems. Steel has high recycling value. Recycled steel may be used, which will become recyclable in the future. Composite metal deck and concrete topping will be used in some buildings. Composite materials are generally harder to disassemble and reuse than homogeneous materials. Roof assemblies Stanford clay roof tile will be used in sloped roof areas, while weathering copper may be used in exposed secondary roofs. Stanford clay roof tile from the existing buildings may be recycled to a local recycling company, or reused on the new sloped roof for the project. Copper could be recycled easily. Roofing materials with good heat reflection will reduce the need for air-conditioning, as well as extend roof lifespan. Eco-friendly green roofs with vegetation will also have a cooling effect. Other envelope assembly materials The vertical cladding will be 50% solid opaque materials and 45% glazing materials. Half of the solid surface is stone. Thin stone veneer composite panels are also under consideration for less visible areas, or areas higher up on the facade. Cubic cut stone 2 Arup, Pre-SD Civil Narrative, 4/30/2007 3 Arup, Outline Specifications, 4/30/2007 4 Environmental Sustainability Task Force, Final Report Green Features, 10/31/2006 2 will be utilized for window sills, wall caps, window returns and flush belt courses. Stone is durable and has future recycling value. R2 Minimize the use of non-renewable resources Goal Develop strategies to minimize the use of non-renewable resources. Incorporate reused and recycled building materials and components. Utilize locally manufactured materials. Avoid tropical hardwoods and use wood products from certified sources for sustainability. Methods and Justification Reused materials Reused materials include excavation materials, stockpile materials and potentially Stanford roof tiles, as discussed in R1. Recycled materials Materials with high recycled content have been considered. Examples of these include steel, carpet, and pre-cast pavers. There are also glass with a 20% post consumer recycled content and certainteed “Prorock” interior partitions with 14% recycled content5. Locally manufactured materials The project uses locally manufactured materials to minimize the environmental impact. Local manufacturers within 500 miles are preferred. However, some of the Stanford University acceptable suppliers include foreign manufacturers, such as Rocamat from France. Certified wood The use of wood will be limited by code considerations. At least 50% of all wood used in the project will be from Forest Stewardship Council (FSC) sources, consistent with sustainable forest practices. Some of the wood species include Maple, Beech or Birch species. Tropical hardwoods are avoided. 5 Arup, Outline Specifications, 04/30/2007 3 R3 Reuse parts of the existing building Goal Maximize the use of existing facades and major structures in the new building. Methods and Justification The construction of the new GSB requires complete demolition of Serra Complex 651 and 655. In the current design scheme, there is little intent to reuse parts of the existing building in the new building. However, parts of the existing building may be reused in other buildings or recycled. Existing facade reuse One exception is the potential to reuse Stanford roof tile since similar roof tiles will be used in the new building to keep the Stanford tradition. Such strategy is proposed by the Sustainability Task Force, and is apparent from the aerial picture of the existing site (Fig. R1) and the schematic drawing of the future site (Fig. R2). Nonetheless, even if Stanford roof tile is being reused, percentage of the existing facades being reused is less than 50%. Fig. R1 (Left): Aerial photo of the existing site (Courtesy of Google Earth) Fig. R2 (Right): Schematic drawing of the new site (Courtesy of Bohlin Cywinski Jackson, Arup, PWP) Existing major structures reuse There is no evidence of at least 50% of the existing major structures being reused. No credit is awarded for this section. 4 R4 Design for durability, adaptability and disassembly Goal Consider durable and low maintenance materials in the project. Incorporate design features to facilitate building adaptability and disassembly. Methods and Justification Building durability Durability is evident in the selection of building materials. For example, the new GSB outline specifications recommend choosing windows, doors and associated assemblies based on durability of the material. Building adaptability Many of the furnitures are movable within the new GSB building. There are also movable walls and modular furnishings. This allows for flexibility in building interiors and classroom configurations. It also allows a learning environment which is adaptable to changing pedagogies and technologies. This is consistent with one of the guiding principles for the project: to promote academic excellence6. Fig. R3: Classroom configuration (Courtesy of Bohlin Cywinski Jackson, Arup, PWP) 6 Environmental Sustainability Task Force, Final Report Executive Summary, 10/31/2006 5 Building disassembly The current design phase does not emphasize building disassembly. However, design options proposed do encourage future building upgrade instead of replacement. An integrated design approach is used in response to rapidly changing technologies for heating, cooling and plumbing. In addition, future recycling values of materials are being considered. R5 Reuse and recycle demolition waste Goal Develop a construction and demolition waste management plan. Methods and Justification The new GSB strives to be a model in recycling. The goal is to salvage or recycle 75% by weight of construction, demolition, and land clearing waste 7. Contractors will be responsible for developing the process and providing documentation. Stockpile materials are identified as suitable for reuse and recycling. Excavation materials will be used on site as fill. Potential locations for reuse of the remaining excavation materials will be identified to minimize waste8. R6 Recycle and compost Goal Recycle consumer products and compost organic waste. Methods and Justification Recycling and composting have been a campus-wide practice for Stanford, and will be assumed in the new GSB. PSSI proposes a 5R program which includes recycling and rotting. Fig. R4: Stanford recycling logo (Courtesy of http://recycling.stanfor d.edu/5r/index.html) Facilities to handle and store consumer recyclables There are currently many facilities that collect paper, glass, plastic and metal for recycling. Separate recycle bins are placed inside and outside buildings for each category. Most of the materials are brought to the processing yard to be sorted and decontaminated. The materials are then sold to local vendors, delivered using roll-off 7 Arup, Outline Specifications, 4/30/2007 8 Arup, Pre-SD Civil Narrative, 4/30/2007 6 trucks. Stanford is proud of diverting 60% of its waste by recycling. Provision to compost organic waste Organic waste includes food, trees, grass and wood, among others. The waste reduction and diversion program accounts for about 20% of the total diversion on campus. It is comprised of yard waste and food waste composting, brush chipping, grasscycling, and wood chipping. Recently, new composting bins have been Fig. R5: Facilities to process recyclable installed in Tressider dining hall to collect paper (Courtesy of organic waste. Composting signs have http://recycling.stanford.edu/5r/recycle_st also been placed in the dining hall to anford.html) promote the use of organic containers and utensils made from potatoes, corns and sugarcane fiber. Similar composting programs are found in the existing GSB building. We therefore expect composting provision to be available in the new GSB as well. Fig. R6 (Left): Food waste composting (Courtesy of http://recycling.stanford.edu/5r/rot_stanford.html) Fig. R7 (Right): Green waste reduction program (Courtesy of http://recycling.stanford.edu/5r/rot_stanford.html) 7 † †† Recommendations † “Yes” gives an upper bound of 80%. “No” gives a lower bound of 40%. credit morea appropriate for for implicit lifecycle assessment. We Partial give the newisGSB score of 60% resources, with a lower and upper bound of 40% and 80% respectively. This is due to the uncertainty in lifecycle assessment, †† Disassembly is not considered explicitly. Design options allow for which accounts for 40% of the total score. In the Green Globes checklist, only yes or no future upgrade instead of replacement. answers are available. This could lead to over- or under-estimation in the evaluation. We feel that the new GSB could get at least partial credit for lifecycle assessment. Many of the analysis in the new GSB seem to be relevant to 8 Fig. R8: Athena software (Courtesy of Athena Institute) lifecycle analysis, however, at this stage, the project team does not specify any intent to perform lifecycle assessment. We strongly encourage the new GSB to pursue credit in lifecycle assessment through the Athena software in later design phases. Athena estimates the environmental impact for a specific building design or a set of building assemblies. This enables the designer to study alternative design options to select the best materials and assemblies based on energy consumption, global warming potential, solid waste emissions, and air and water pollution. The Athena software will be available for free in early June this year. Another alternative software for lifecycle assessment is BEES (Building for Environmental and Economic Sustainability), developed by the NIST (National Institute of Standards and Technology) 9. If the new GSB does not reuse parts of the existing building, it would be helpful to consider component reuse in other locations. Although building retrofit is preferred over replacement, it would also be beneficial to design for building disassembly in the event that replacement is needed. Note that Green Globes has separate evaluations for eight design phases. Scores may vary across design phases. A low score in earlier design phases may call for changes and improvements in later phases, which could eventually lead to a higher overall score. 9 NIST, BEES, http://www.bfrl.nist.gov/oae/software/bees.html 9