- Public Surplus

advertisement

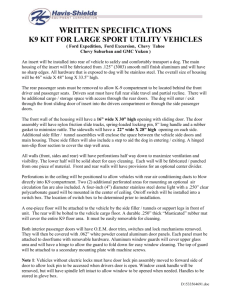

VANCOUVER FIRE DEPARTMENT SPECIFICATIONS FOR RESCUE VEHICLE INTENT OF SPECIFICATIONS It shall be the intent of these specifications to cover the furnishing and delivery of a complete rescue vehicle equipped as hereinafter specified. These specifications cover only the general requirements as to the type and construction and test to which the apparatus shall conform, together with certain details as to finish and equipment with which the successful bidder shall conform. Minor details of construction and materials, which are not otherwise specified, are left to the discretion of the contractor, who shall be solely responsible for the design and construction of all features. The vehicle proposed by the bidder shall meet the requirements of the National Fire Protection Association (NFPA) as stated in the current applicable pamphlet, all chapters except where amended herein. Loose equipment shall be provided only as stated in the following pages. A written proposal accompanied by a set of “Contractor’s Specifications” consisting of a detailed description of the apparatus and equipment proposed and to which the finished apparatus will conform shall be supplied by the contractor. These specifications shall indicate size, type, model and make of all components and equipment. The contractor shall also indicate the following dimensions and capacities. Apparatus Wheel Base____________________ Cab to Axle_____________________________ Overall Length___________________________ Overall Height___________________________ SAE Turning Radius______________________ Apparatus Weight________________________ Angle of Approach_______________________ Angle of Departure_______________________ QUALITY OF WORKMANSHIP The design of the apparatus shall embody the latest approved automotive engineering practices. The workmanship shall be of the highest quality in its respective field. Special consideration shall be given to the following points: Accessibility of various units which require periodic maintenance, ease of operation and symmetrical proportions. Construction shall be rugged and ample safety factors shall be provided to carry the intended loads. The apparatus construction shall meet the requirements outlined in the National Truck Equipment Association, Ambulance Manufacturers Division Standards and Federal Specification KKK-A-1822E. 1 DELIVERY A qualified contractors representative shall deliver the apparatus and remain for a sufficient length of time to instruct personnel in the proper operation, care and maintenance of the equipment delivered. DELIVERY DATE The contractor must specify a delivery date from the time of receipt of a purchase order. INFORMATION REQUIRED The manufacturer shall supply at the time of delivery, complete operation and maintenance manuals covering the completed apparatus as delivered. A permanent plate shall be mounted in the driver’s compartment which specifies the quantity and type of fluids required including engine oil, engine coolant, and transmission. PERFORMANCE TESTS AND REQUIREMENTS The delivered apparatus shall comply with all applicable testing requirements as outlined in the National Fire Protection Association, Federal KKK and AMD Standards. FAILURE TO MEET TESTS In the event the apparatus fails to meet the test requirements outlined in these specifications on the first trial, second trials may be made at the option of the bidder within 30 days of the date of the first trial. Such trials shall be final and conclusive and failure to comply with these requirements shall be cause for rejection. Failure to comply with changes to conform to any clause of the specifications, within 30 days after notice is given to the bidder of such changes, shall also be cause for rejection of the apparatus. Permission to keep or store the apparatus in any building owned or occupied by the purchaser or its use by the purchaser during the above specified period with the permission of the bidder shall not constitute acceptance. LIABILITY The successful bidder shall defend any and all suits and assume liability for the use of any patented process including any device or article forming a part of the apparatus furnished. EXCEPTIONS TO SPECIFICATIONS All exceptions shall be stated no matter how seemingly minor. Any exceptions not take shall be assumed by the purchaser to be included in the proposal, regardless of the cost to 2 the bidder. Exceptions requested by the vendor shall be written on a separate paper with the following information supplied for each exception taken: 1. Page number and paragraph of specification 2. Exact wording found in the city specification 3. Reason for taking the exception 4. Proposed change to specification Exceptions shall be submitted in the same sequence as the specification for each of evaluation. Vendors taking total exception to the specification shall not be acceptable. BLUEPRINT A drawing (print) of the proposed apparatus shall be provided by the vendor and must be approved by the fire department prior to construction of the apparatus. This drawing shall indicate the location of lights, siren, horns, compartments and other major components. The drawing shall also include the apparatus dimensions. The fire department will not approve construction until all necessary changes to the drawing have been made. WARRANTY The apparatus shall be warranted to be free from defects in materials and workmanship under normal use and service. The manufacturer shall supply a copy of the warranty or warranties that they propose to provide. In no case shall it be less than (1) one year on the entire apparatus. The warranty period shall begin after the apparatus is accepted and in-service. All other warranties as outlined in these specifications shall be provided in writing as part of the vendor package. Failure to provide warranties as outlined throughout these specifications shall be cause for rejection. BID BOND The vendor shall provide a bid bond in the amount of 5% of the proposed price. The bid bond shall reference the warranty coverage and terms of the face of the bond. CHASSIS The chassis shall be a Ford F-450, 4x2, with the Ambulance Prep Package, and a 3 year/36,000 mile “Bumper to Bumper” warranty. The chassis shall be provided by the vendor. 3 WHEELBASE AND CAB TO AXLE The chassis shall have a 165” wheelbase with dual rear wheels and an 84” cab to axle. GROSS VEHICLE WEIGHT RATING The chassis shall have a GVW rating of 15,000 pounds. CURB WEIGHT The curb weight of the chassis shall be approximately 10,500 pounds. PAYLOAD The apparatus shall have a minimum payload of 4,500 pounds. AXLE RATING The axles shall be rated at 6,000 pounds on the front and 11,000 pounds on the rear. ENGINE The engine shall be a 6.0 liter turbo diesel with a 5 year/100,000 mile warranty. The engine shall include the external oil cooler, factory diesel package, and 1,000 watt engine heater. The engine shall have a heavy-duty dry type air cleaner with flow restriction indicator. ENGINE COOLING SYSTEM The cooling system shall be a heavy-duty, closed –air, free-liquid state type with coolant recovery system. The cooling system shall be protected wit a 50/50 solution of permanent type antifreeze to -40 degrees F. The cooling system shall have corrosion inhibitor added in the proper quantities to meet the manufacturer’s recommendations. TRANSMISSION The transmission shall be a heavy-duty automatic with four (4) speeds forward and one (1) reverse. The transmission shall include an external oil cooler located in the chassis grill area. REAR DIFFERENTIAL The rear differential shall have a ratio of 4.30, limited slip, wide track rear axle. 4 SHOCK ABSORBERS The shock absorbers shall be heavy-duty OEM both front and rear. SPRING CAPACITY There shall be a combined spring capacity of approximately 6,000 pounds at the front and 11,000 pounds at the rear. STEERING The steering shall be power assisted with a tilt steering wheel. STABILIZER BAR The vehicle shall be provided with an OEM front and rear stabilizer bar. BRAKES The brakes shall be heavy-duty power assisted front and rear disc with a four-wheel antilock brake system. The front brakes shall be 14.53” diameter and the rear shall be 15.55” diameter. EXHAUST SYSTEM The vehicle shall be equipped with an exhaust system in accordance with Federal Motor Carrier Safety Regulations, part 393.83. the exhaust shall be suspended using three (3) hangers, excluding the manifold attachment. The exhaust system shall discharge at the right rear side of the module. The tailpipe outlet shall not terminate within six (6) inches of the vertical axis of the fuel tank filler opening. TIRES AND WHEELS The tires and wheels shall be OEM supplied 225/70R-19.5 all season belted radials on 6.0 inch rims. A total of seven (7) shall be supplied. The spare tire and wheel shall be shipped loose. GAUGES AND METERS The chassis shall include a tachometer, trip odometer, transmission temperature, oil pressure, coolant temperature, fuel gauge and indicator lights in addition to the speedometer. 5 BATTERY SYSTEM The batteries shall consist of dual 850 CCA OEM batteries located in the engine compartment. ALTERNATOR AND REGULATOR The alternators shall be dual 115 amp OEM supplied. CLIMATE CONTROL SYSTEM The system shall be the chassis manufacturers OEM system, heavy-duty, fresh-air, high capacity heater/defroster and dehumidifying air conditioning system. HORNS The horns shall consist of OEM supplied dual pitch electric horns. CAB SEATS The seats shall be high-back captain’s chairs wit combination lap and shoulder harness. The seats are to be cloth covered, have retractable arm on the inside and a side door armrest. The seats shall be OEM. FUEL CAPACITY A single fuel tank shall be supplied with a total capacity of not less than 40 gallons. WINDOWS All chassis windows shall be tinted safety glass. WINDSHIELD WIPERS The wipers shall be electric with interval speed control and washer system. REAR VIEW MIRRORS The mirrors shall include one (1) interior day/night rear view mirror and two (2) black, below eye level, manually telescoping trailer tow exterior mirrors with power glass, and two-way fold. The upper portion of the mirror shall be 7” wide x 8.25” high. The lower portion shall be convex and be 6.5” wide x 2” high. 6 TRIM AND ACCESSORY ITEMS The chassis shall be the “XLT” level. The interior shall include dual air bags, padded sun visors, dash, door pockets, dual adjustable dome lights, reduced sound package, carpeted floors, molded cloth headliner, cup holders, auxiliary power point, interior hood release and red door reflectors. The exterior shall have a chrome front bumper, two (2) front tow hooks, single beam jewel effect headlamps, roof clearance lights, and under hood service light. The cab doors shall have power windows and electric door locks. Cruise control shall also be included. A hidden door open button shall be installed in the grill area to facilitate opening of the apparatus should a door inadvertently be locked with the keys inside. AUTO THROTTLE An OEM installed auto throttle system shall be installed which will automatically adjust for changes in electrical load and automatically disengage when the brake is applied or the vehicle is placed in gear. RADIO AND SPEAKERS The unit shall have an OEM installed AM/FM stereo radio with digital clock and speakers installed. CHASSIS COLOR The exterior cab color shall be Sikkens FLNA 3035, dark red. A color sample is required by the fire department prior to painting the apparatus. The interior color shall be dark gray. DOORSTEPS The door steps shall be covered with heavy molded color coordinated scuff pads. THE FOLLOWING CHASSIS MODIFICATIONS SHALL BE MADE BY THE APPARATUS MANUFACTURER SIMULATORS Stainless steel wheel simulators shall be installed on all outer wheels. Provisions shall be made to allow user to easily check and/or add air as necessary. Valve stem extenders are acceptable. 7 EXHAUST HEAT SHIELDS Exhaust heat shields shall be formed from 18 ga. Galvanized steel sheets with stamped reinforcements and formed edges. Access openings shall be provided for shock absorber mounting bolts etc. Heat shields shall be bolted to the chassis frame and extend from the back of the cab to the frame cross member behind the rear axle. RUNNING BOARDS WITH SPLASH GUARDS Running boards shall be installed on both sides of the vehicle. The shall be made of .125” polished aluminum diamond plate. The running boards shall be flared to the front corner of the module. The splashguards shall be welded to the forward end of the running boards. The entire assembly shall be securely mounted with stainless steel .25”20 truss head bolts. The assembly shall be ruggedly constructed and be able to support the weight of the driver or passenger without deforming. RUBBER MUD FLAPS Mud flaps shall be installed behind each set of rear wheels. AIR SUSPENSION Air suspension shall be provided and installed. The system shall be a Granning Air Ride System, with the “air dump” feature. The system shall activate when the rear streetside patient compartment entrance door opens. An override switch in the driver’s console shall be provided. MODULE TO CHASSIS MOUNTING SYSTEM MODULE MOUNTING SYSTEM The module shall be bolted to the chassis frame in twelve (12) locations. Each mounting location shall include a hard rubber isolation pad between the chassis frame and the module lateral frame. Eight (8) .75” grade 5 bolts shall extend through the lateral and sides of the frame member and bolt to the web of the chassis frame with .75” grade 5 bolts. The four (4) rearmost bolts shall be .625”. All bolts shall be secured with locking nuts. CAB TO MODULE ATTACHMENT The module shall be attached to the cab with a flexible watertight boot to allow cabbody flex as designed by the chassis manufacturer. The chassis back shall be modified and reinforced with a welded steel framework. The rear window openings on each side of the module access shall be covered with 18 ga. Steel and painted to match the body. 8 MODULAR CONSTRUCTION All material utilized shall be of the correct type, alloy, and thickness to withstand the intended usage and provide protection against cracking, corrosion, or metal fatigue. All materials utilized shall be of open stock origin, commonly available through local sources for rapid and economical repair of modification of the body. Any use of proprietary parts or material in the construction of the body is unacceptable due to potential delays or difficulties in future repair or service. Where brand, make, or model of equipment has been specified, no exceptions shall be taken. Where compartment and cabinet sizes have been specified the vendor must substantially (plus or minus 1”) build the compartment to the size specified. The module shall have a transferable lifetime structural warranty. MATERIAL Extrusions Size Structural Tubing Structural Tubing Cross Members Cross Members 1” x 2” x .125” sq. 2” x 2” x .125” sq. 3” x 3” x .375” 1.5” x 3” x .25 Formed Sheeting Size Skin/Roof/Compartments Subfloors/Doors Interior Cabinets Diamond Plate Stainless Steel .125” .090” .125”/.08” 16ga., 20ga. Alloy 6063-T52 6063-T52 6061-T6 6061-T6 Alloy 5052-H32 5052-H32 3003-H32 304 # 4B MODULE DIMENSIONS Overall Vehicle Dimensions: Length: Width: Height: 22’ 0” 7’ 10” 8’ 11.125” (264”) (94”) (107.125”) Exterior Module Dimensions: (minimums) Length: Width: Height: 12’ 3” 7’ 10” 7’ 4.375 (147”) (94”) (88.375”) Interior Module Dimensions: (minimums) 9 Length: Width: Floor Width: Height: Load Height: Forward Wall to Rear Doors Left Wall to Right Wall Left Cabinets to Squad Bench Floor to Ceiling Ground to Floor Height 139” 89” 50” 72” 33” STRUCTURAL FRAMING Side wall and rear wall construction shall consist of 2” x 2” x .125” aluminum square tubing extensions welded together with a maximum of 14” centers. 1” x 2” x .125” aluminum tubing may be utilized in addition to the 2” x 2” tubing to accommodate custom compartment sizes. The bottom of the wall structure shall be sealed with welded 2” x 2” tube, 2” x 2” angle or .125” plate depending on location. Wall structure shall be capped with a 2” x 2” x .125” header upon which the 2” x 2” x .125” roof structure is welded. This process provides a unitized roll cage structure for greater occupant safety. The front wall structure shall be constructed of minimum of 1.25” x 3.875” x .125” formed aluminum channel to allow ample space for wiring raceways, heater/AC hoses, and cold air return duct. FOUNDATION SYSTEM The foundation shall consist of a .125” aluminum sheet subfloor with foundation members securely welded under the subfloor. Members shall consist of six (6) 3” x 3” x .375” structural angles, with two (2) .250” x 1.5” aluminum members running lengthwise between the structural angles. MODULE SEAMS All body and compartment seams at or below the floor level shall be full seam welded. The entire perimeter of the subfloor shall be completely sealed with a caulking material, creating a watertight, dust-free module environment. EXTERIOR SKIN In addition to welding the exterior skin to structural framing, a Norton very high bond system shall be utilized full length on all wall and roof frame members. A polyurethane adhesive sealant shall be applied to the edges of structural tubing at the exterior wall surfaces. MODULE ROOF In order to improve module strength and reduce roof seams the following roof system shall be utilized. The roof shall be seamed in the center, have a 1.5” radius at the corners, and provide a weatherproof overlap of the aluminum side sheets 5.25” below the roofline. The roof shall be supported by positive contact between sidewall framing and roof framing. All seams on the roof surface shall be full seam welded on the outside and 10 caulked on the inside. The module roof edges, front and rear, shall be constructed to allow mounting of recessed light bars. This roof design shall have been tested to meet AMD standards and a detailed exploded drawing of the roof structure shall be provided. In order to avoid the possibility of paint and/or weld cracking, no extrusions shall be used in the exterior construction of the roof or corners of the vehicle. MODULE EXTERIOR COMPARTMENTS All compartments are constructed from formed .125” aluminum and are securely welded to the subfloor and structural framing. A baffled drain hole shall be provided in all exterior compartment bottoms that extend below the floor line. All exterior adjustable shelves shall be mounted on heavy-duty aluminum unistrut track, which is securely welded to compartment interiors. Each shelf shall support at least 300 lbs. of equipment. COMPARTMENT DIMENSIONS Compartment #1 Interior Dimension: Door Dimension: Location: Shelving: Door: 15.5” wide x 65” high x 19” deep, lower and 12” deep in the upper 15.5” wide x 65” high Streetside, forward None Single Additional: A 110VAC power box shall be installed in the forward wall, recessed so as not to protrude into the compartment. The upper portion of the compartment shall have two (2) horizontal strips of unistrut for installation of SCBA brackets. Hard wire for future of 12V DC flashlight. Compartment #2 Interior Dimension: Door Dimension: Location: Shelving: Door: 32” wide x 35” high x 19” deep 32” wide x 35” high Streetside, forward of wheel well One (1) adjustable Single Additional: One (1) 110V AC outlet shall be installed in the compartment. There shall be a close out in the bottom right rear corner to allow for chassis leaf spring movement. Compartment #3 Interior Dimension: Door Dimension: Location: 15.5 wide x 65” high x 19” deep, lower and 12” deep in the upper 15.5” wide x 65” high Streetside, rear 11 Door: Single Additional: The upper portion of the compartment shall have two horizontal strips of unistrut for installation of SCBA brackets. Hardwire for future installation of 12V DC flashlight. Compartment #4 Interior Dimension: Doorway Dimension: Location: Shelving: Door: 18” wide x 77” high x 19” deep 18” wide x 77” high Curbside, rear None Single Additional: This compartment shall have three (3) straps setup for storage of an “M” or “H” size cylinder. Two (2) backboard restraining straps shall be installed on the aft wall. A formed stainless steel gasket cover shall be installed so that backboards do not cut gasket material. Compartment #5 Interior Dimensions: Doorway Dimension: Location: Shelving: Door: 18” wide x 17.375” high x 19” deep 18” wide x 17.375 high Curbside, aft of wheel well None Single Additional: There shall be a close out in the bottom right rear corner to allow for chassis leaf spring movement. Compartment #6 Interior Dimensions: Doorway Dimension: Location: Shelving: Door: 25.5” wide x 52.5” high x 32” deep 25.5” wide x 52.5 high Curbside, forward Two (2) adjustable shelves, with 1” lip down on exterior side Single Additional: this compartment shall provide inside/outside access and have a full width stainless steel threshold on the floor level shelf. The below-floor portion of this compartment shall be for battery storage, with a rollout tray capable of holding two (2) Interstate 31-ECL 700 CCA, 875 CA batteries. The area shall be vented to the outside and sealed to prevent battery vapors from entering the patient area. 12 MODULE DOORS The doors shall be box pan formed with a total thickness of 2”. DOOR HINGES Each doorframe will have a .875” flange for the installation of an air cell hollow core, 360-degree compression seal. This seal creates a watertight, dust-free compartment. The door seal shall be knock-on type. DOOR LATCHES Shall be flush mounted, stainless steel, Verch paddle type slam latches with rotary latch striker posts, which meet FMVSS 206 requirements. The striker shall be adjustable and shall be secured with a nut from behind the doorframe. The striker washer will not be removed. Cold rolled, threaded .162” steel rods shall be used to activate dual rotary latches. Once final adjustments to latches are made, threads are to have Locktite or equivalent applied. All double door compartments shall have an exterior stainless steel paddle handle and rotary latches on each door, eliminating latch interference with adjustable shelves. Door will latch to doorframe mounted striker posts only and not to one another. All entrance doors shall have interior handles with dual point, rod actuated, rotary latch systems, which are lockable inside and out. All compartment and module access doors shall be keyed for #510CH keys. COMPARTMENT DOOR CONTROL A heavy-duty, double spring door control capable of holding the door open at approximately a 90-degree angle on any road surface shall be installed at the top of each compartment door. CURBSIDE DOOR CONTROL The curbside door control shall be a heavy-duty, double spring door check installed at the top of the door. This door check will hold the door open at approximately a 90-degree angle on any road surface. REAR DOOR CONTROL Shall be Cast Products “grabber” type hold-open devices with replaceable rubber catches. COMPARTMENT DOOR SKINS The door skins shall be .80” bright aluminum diamond plate or machine swirled and be removable to service door hardware. Reflectors shall be added to the bottom outboard corner of each door. 13 ENTRANCE DOORWAYS One (1) curbside and two (2) rear module entrance doors shall be provided. The curbside doorway dimensions shall be 28” W x 69.75” H. The rear doorway dimensions shall be 49.75 W x 66” H. THRESHOLDS All compartment and module access doorframes shall have full width formed stainless steel threshold plates to protect the lower edge of the frame. MODULE INTERIOR COMPARTMENTS The interior compartments shall be formed of .090” aluminum and shall be securely welded or mounted to the structural framing. All interior adjustable shelves shall be mounted on 1” wide aluminum Unistrut track. CABINET #1 Dimensions: 37.75”W x 13.75”H x 7.0”D Location: Streetside, upper forward Shelving: One (1) adjustable Door(s): Sliding, clear .177” acrylic with felt lined anodized aluminum track and full extruded aluminum door pulls. CABINET #2 Dimensions: 37.75”W x 13.75”H x 14.75”D Location: Streetside, upper center Shelving: One (1) adjustable Door(s): Sliding, clear .177” acrylic with felt lined anodized aluminum track and full extruded aluminum door pulls. CABINET #3 Dimensions: 34”W x 13.75”H x 14.75”D Location: Streetside, upper rear Shelving: One (1) adjustable Door(s): Sliding, clear .177” acrylic with felt lined anodized aluminum track and full extruded aluminum door pulls. CABINET #4 Dimensions: 50”W x 16”H x 19”D (fore), 7.0”D (aft) Location: Streetside, center rear 14 Shelving: One (1) adjustable Door(s): Sliding, clear .177” acrylic with felt lined anodized aluminum track and full extruded aluminum door pulls. Additional Instructions: Adjustable shelf shall be notched to accommodate the change in depth. CABINET #6 Dimensions: 20” W x 15.5”H x 19”D Location: Streetside, aft of CPR seat Additional Instructions: Open storage CABINET #7 CPR Seat with Storage Dimensions: Bench: 24”W x 18.75”H x 19”D Storage: 24”W x 8.125”H x 19”D Location: Streetside Door(s): A lid, with a 1.5” overhand, shall provide access to the storage area and have an automatic hold-open device, paddle latch, and 3” high-density foam padding covered with heavy duty vinyl utilizing nonbeaded edges. Additional Instructions: There shall be a 20”W x 14.875”H open storage area at the aft end of the bench. The CPR seat back pad shall have 1” high-density foam padding covered with heavy-duty vinyl utilizing nonbeaded edges. One (1) set of seatbelts shall be installed on the seat. The CPR seat base shall be formed from aluminum and securely anchored to the sub-floor. The bottom and unfinished sides of the storage area shall be lined with indoor/outdoor carpet. CABINET #8—Action Area Dimensions: 39”W x 31.75”H Location: Streetside Additional Instructions: The action area shall contain an attendant control panel, vacuum connection, suction collector, oxygen outlet, thermostat, blower switch, 12VDC outlet, and 110VAC outlet. The entire action wall area shall be lighted utilizing a Thin-Lite Model #612 light with 12VDC dual 11” fluorescent bulbs. A full depth counter top shall be located below the action wall. The counter top shall be one-piece 16 gauge, 304 stainless steel with a .5” aluminum retaining lip. A sharps and waste container shall be located at the aft end of the counter accessible through a flip up lid. CABINET #9 Dimensions: 10” x 40.75”H x 18”D Location: Center forward, behind the attendant seat. Shelving: One (1) adjustable Door(s): A polycarbonate, hinged door and a SoCo twist lock. Additional Instructions: This cabinet shall be supplied with access to the power component panel. 15 CABINET #10—Attendant Seat Cabinet Dimensions: 29”W x 12.25”H x 18”D Location: Center forward Additional Instructions: This cabinet shall be open to the aisle side. CABINET #11 Dimensions: 29.875”W x 10”H x 9”D Location: Curbside, upper rear Door(s): Sliding, clear .177” acrylic with felt lined anodized aluminum track and full extruded aluminum door pulls. CABINET #13—Squad Bench with Storage Dimensions: Bench: 62.5”W x 18.75”H x 19.5”D Storage: 62.5”W x 8.125”H x 19.5”D Location: Curbside Door(s): A lid, with a 1.5” overhang, shall provide access to the storage area and have an automatic hold-open device, paddle latch, and 3” high-density foam padding covered with heavy duty vinyl utilizing nonbeaded edges. Additional Instructions: An oxygen outlet shall be mounted on the wall over the aft portion of the bench. The squad bench back and/or head pads shall have 1” high density foam padding covered with heavy duty vinyl utilizing nonbeaded edges. Three (3) sets of seatbelts shall be installed on the bench and set up for use with sit-up or stretcher subfloor. The bottom and unfinished sides of the storage area shall be lined with indoor/outdoor carpet. The wall over the back pad and at the aft of the squad bench shall be covered with white-board. CABINET #14 Dimensions: 32”W x 16”H x 27.875”D Location: Front, right, upper Additional Instructions: The cabinet shall house the AC/heating unit. CABINET #15 Dimensions: 31.75W x 9.625”H x 27.875”D Location: Front, right, center Door(s): Sliding, clear .177” acrylic with felt lined anodized track and full extruded aluminum door pulls. Additional Instructions: An IV warmer shall be installed in the right side of the cabinet. CABINET #16—Drawers Dimensions: 31.75”W x 38”H x 27.875”D 16 Location: Front, right, center under cabinet #15 Additional Instructions: Two (2) 13”W x 5”H x 19”D metal drawers. Each drawer shall operate on 18” slides rated at 300 lbs. per set and have a gas shock hold open/close device to ensure drawers to no accidentally open or close during the operation of the vehicle. Drawers shall be formed of 16 ga. Steel welded construction with an automotive gray enamel finish, and formed structural supports on the sides and front of drawers. Each drawer shall have machine stamped divider supports along the side for at least four (4) dividers per drawer with four (4) adjustable dividers provided with each drawer. CABINET #17 Dimensions: 31.75”W x 38”H x 27.875”D Location: Front, right, lower Shelving: Two (2) adjustable Additional Instructions: The lower portion shall provide inside/outside access and have one (1) 110VAC outlet and one (1) 12VDC outlet installed on the back wall. A ribbed mat shall be secured with anchors to prevent slipping when kits are removed. CABINET #18—Electrical Compartment Dimensions: 35”W x 13”H x 10”D Location: Front, center, above pass-thru area Door(s): An aluminum, hinged, swing up door with a hold-open device, a rotating lock, and an automatic compartment light shall be installed. Additional Instructions: This cabinet shall house the electrical component module. SIDE DOORSTEP A recessed curbside doorstep shall be provided which is 9.5”D x 28”W. There shall be a drain hole and an open grate step plate, which is removable for cleaning purposes. A polished aluminum diamond kick plate panel shall be installed on the sides and face of the doorstep. CAB TO MODULE PASSAGE There shall be a walk-through measuring 17.25”W x 37”H. COATINGS AND FINISHES MODULE FINISH PREPARATION The module shall be seam sealed and all imperfections on aluminum surfaces of the module shall be sanded smooth. The entire exterior shall be mechanically etched and washed with wax and grease remover to ensure proper primer and paint adhesion. 17 MODULE PRIMER The module shall be primed with epoxy primer prior to applying the finish coat of acrylic urethane paint. PAINT TYPE The paint shall be BSAF “UNO” acrylic urethane. COLOR SCHEME The base color shall match Sikkens #3035 Dark Red. CHASSIS COLOR The chassis shall match Sikkens #3035 Dark Red. COMPARTMENT FINISH All compartments shall be machine swirled or diamond plate with NO PAINT on the interior of the compartments or the inside of the compartment doors. INTERIOR CABINETRY FINISH All interior cabinetry shall be sanded, etched, washed, primed, and painted light gray (#13245). MODULE UPHOLSTERY The interior upholstery shall be gray in color. The actual material shall be approved by the fire department prior to installation. MODULE FLOORING MATERIAL The flooring shall be Glacier (color #16001) Assurance Slip-Resistant Sheet flooring providing durability, ease of maintenance and stain resistance. It shall contain a high concentration of aluminum oxide particles suspended throughout the entire wear surface for slip-retardent performance over .750” solid core, 7-ply, industrial grade plywood. The flooring shall have an overall thickness of .080” nominal and be manufactured in accordance with ASTM F1303-97 Type II, Grade 1 standards. Flooring shall meet ASTM D2047 Slip Resistant, ASTM F970 Static Load, E662 and E648 Fire Data Tests. It shall be seamless and cove up the sidewalls a minimum of 5” as a seal. 18 COMPARTMENT LINING The compartment floors shall be lined with light gray Mate’flex material and all shelves with easy sweep mat. CABINET LINING The interior cabinet shelves shall be lined with easy sweep mats, which are removable for ease of cleaning. SURFACES AND FINISHES All surfaces and finishes shall be impervious to soap, disinfectants, and water, to permit washing and sanitizing. AUTOMOTIVE UNDERCOATING SEAL The entire chassis and module underbody (excluding drive shafts, wheels, exhaust system, and lubrication fittings, per manufacturer’s specifications) shall be sprayed with undercoating for reduced corrosion and added sound deadening. MODULE EXTERIOR STEP/BUMPER The step/bumper shall be of welded construction of 3” x 3” x .375” aluminum angle and 2” x .25” plate and shall be covered with .125” bright aluminum diamond plate. The center section, below the doors, shall have a plasma cut open flow design to prevent accumulation of water and show and provide a 7” step. The outermost 12” of each end shall be angled to prevent dragging of corners in high angle of approach/departure areas. Diamond plate shall be formed on front and rear edges for channel type strength and a formed .090” aluminum close out shall be welded to the underside of the step/bumper. The bumper shall be bolted directly to the chassis frame using high strength Grade 5 bolts. The bumper shall be easily removable and replaceable in case of damage. The step/bumper shall be designed to accommodate a one person cot. 19 RUB RAILS The rub rails shall be bright finished extruded aluminum of a double channel design and .125” wall thickness for maximum strength. The rub rails shall be 2.5” high x .75” wide and run along the lower edge of the body, interrupted only by wheel well openings. FENDER RINGS Fender rings shall be installed on the module. They shall be bright polished aluminum with a rounded outer edge following the full contour of the wheel well opening. DRIP RAIL The drip rail shall be extruded, anodized aluminum running full length of module at the top of the sides and rear and over each exterior compartment. The drip rails shall be installed with stainless steel screws and be detachable for easy replacement. ROCK GUARDS The rock shall be made of bright aluminum diamond plate shall cover the front module corners 24” up from the bottom of the body, 2.5” down the side of the body, and 15” across the front of the body. REAR STEP GUARD The rear step guard shall be made of bright aluminum diamond plate and shall extend from the top of the rear step to the bottom of the rear doors, full width formed around corners, ad 2.5” forward on each side. FUEL FILL(s) The fuel fill(s) shall be on the street side of the module. Each location (if more than one is necessary) shall have a polished cast aluminum fill well and be properly vented. All fuel filler hose shall be protected with a .125” aluminum protection plate. The fuel fills shall be installed in accordance with the body builder and chassis builder’s recommendations. Operators must be able to “fuel” the vehicle on level ground without fuel “burp” while rapidly filling. MODULE WINDOWS The module windows shall have black anodized aluminum frames, rubber gaskets, and be attached with screws for ease of replacement. All module windows shall be dark tinted. The side door window shall be 18.75” x 18.75” with sliding glass, a positive catch, and a screen. The rear door windows shall be 18.75” x 18.75” fixed glass to prevent exhaust from entering the module. 20 MODULE INTERIOR All interior hangers, supports, fasteners, latches and hinges shall be of near flush type design when not in use. The patient compartment shall be free of sharp projections. Exposed edges and corners shall be broken with a radius, chamfer, or Covered with aluminum trim, plastic molding or rubber edging. UPPER WALL COVERING The upper wall covering shall be covered with light gray heavy grade .125” ABS vinyl. All panels shall be attached with a Norton very high bond system. HEADLINER The headliner shall be a one-piece fiberglass reinforced .080” “Glasboard ” with textured white surface. MODULE ACCESS OPENING BUMPERS The module access opening bumpers shall be located over all module access openings and shall be made with 1” high-density foam covered with heavy-duty vinyl matching upholstery. LOWER WALL COVERING The squad bench sides and lower portion of the streetside wall shall be nonporous, colorcoordinated material. GRAB RAIL Two (2) 75” long x 1.25” diameter stainless steel grab rails with three (3) support brackets and shall be securely mounted to roof structural framing over the cot. ACCESS DOOR GRAB RAILS Each module access door shall have a 1.25” stainless steel grab handle. The rear doors shall have “L” style handles, which may also be used as entry assist rails. The side door shall have a 12” horizontal bar. PLASMA HANGERS Two (2) retractable dual plasma hangers with stabilizers shall be near lush mounted in the ceiling over the primary cot. 21 COT MOUNT A Stryker Model 6370 center mount cot fastener shall be installed. A side mount cot fastener shall also be installed. ATTENDANT SEAT A rear facing high-back bucket seat, upholstered with heavy grade vinyl, shall be located at the head of the cot position and provide easy access to all action wall controls and outlets and to the patient. The seat shall be securely anchored to an aluminum storage cabinet. The seat shall have provisions to secure a child safety seat if necessary. OXYGEN SYSTEM The entire oxygen system shall be assembled with certified Oxygen hose (1000 PSI burst strength) with brass fittings, pressure tested, and certified. Ohio type outlets shall be installed in the following locations: one (1) in the action area, one (1) in the ceiling above the primary patient area, and one (1) in the curbside wall above the squad bench. A 50-PSI regulator and one (1) oxygen tank wrench shall be included. SUCTION PUMP The unit shall have an electric pump as the source of suction. Control shall be on the attendant panel. The suction pump shall be vented to the outside of the vehicle under the module body. SUCTION COLLECTOR A Rico Model RS4X-100 B suction collector with a disposable canister shall be installed in the action area. SEATBELTS The seatbelts shall be DOT certified and shall be installed with all passenger seating. Three (3) sets shall be installed on the squad bench and set up for use with sit-up or stretcher patients. The attendant seat and the CPR seat shall each have a single seat belt. INSULATION The module sides, ends, roof, and doors shall be insulated to enhance the interior environment and to prevent heat, cold and external noise from entering the module. The thickness shall depend on the location and available space. In addition, a Norton VHB system shall be utilized on side walls and roof to provide a thermal and noise break between the outside skin and structural members. 22 MODULE CLIMATE CONTROL SYSTEM The module climate control system shall incorporate a heating/air conditioning unit with 42,000 BTU heating and 36,000 BTU cooling capacity. The unit shall have a 750 CFM fan and have controls independent of the cab system. The module system shall be controllable by a thermostat located on the action area wall. EXTERNAL AIR INTAKE To supplement heated or cooled air with fresh air, an external air intake shall be provided on the side of the module. The intake shall consist of six (6) stamped louvers above the side passage door. The interior chamber of the intake shall be made of aluminum and formed to prevent the collection of moisture. Designed into the front right bulkhead wall shall be an air return, which runs from the floor level to the heater A/C unit. The air return vent shall have formed louvers. EXHAUST VENT A motor-powered exhaust vent shall be located in the curbside rear corner of the module. NO SMOKING/FASTEN SEAT BELT SIGNS Two (2) “No Smoking/Fasten Seat Belt” signs shall be installed, one (1) each for the driver area and the module. WHITE MARKER BOARD White marker boards shall be installed on the wall over the squad bench and on the wall at the end of the squad bench to the rear doors. A 16” x 16” white board shall be mounted on the aisle side of the right front stack. An additional white board shall be installed on the wall behind the CPR seat. SHARPS/HAZARDOUS WASTE CONTAINERS One (1) sharps and one (1) hazardous waste container shall be provided and installed in the action area counter. OXYGEN WINDOW An oxygen window shall be clear, 6” x 10”, acrylic window. The window shall be mounted with self-closing hinges. 23 ELECTRICAL All added body and chassis electrical equipment shall be served by circuits separate and distinct from the vehicle chassis circuits. All vehicle wiring shall be copper and conform to all SAE J1128 requirements. The wiring shall be colored, numbered and function coded every 3” for permanent identification and correspond with the vehicle schematics. Solderless, insulated connectors shall be used. Wiring panduit shall be used in power component module to ensure air circulation throughout power component wiring. The wiring shall be routed in conduit or looms and wiring shall be secured to the underbody or frame and insulated metal cable straps. All power distribution cabling shall be covered with a protective split loom. Where wiring passes over exhaust, a heat shield shall be installed. Wiring an electrical components shall not be equipped with positive locking plugs to provide easy disconnect for remount or repair of the body. All wiring devices, switches, outlets, etc., except circuit breakers, shall be rated to carry 125% of the maximum ampere load for which the circuit is protected. OVERLOAD PROTECTION DEVICES The body electrical wiring shall utilize overload protective devices of the automatic reset, circuit breaker type. In addition, one (1) single pole, 20-amp circuit breaker shall be provided for future use. The circuit breakers, relays, and other electrical items shall be located in the enclosed power component module. VOLTMETER A voltmeter shall be installed. AMMETER A 300-amp analog ammeter shall be installed , located in the drivers console. IGNITION CONTROL The chassis electrical circuits will be controlled by the ignition switch as provided by the OEM chassis manufacturer. The auxiliary chassis related functions shall be powered by one (1) 100-amp continuous duty solenoid (rear heater/air conditioner, siren, spotlight, etc.) MODULE POWER Module power shall be controlled by a console-mounted switch, which activates one (1) 100-amp continuous duty solenoid located in the power component module. 24 WIRING ACCESS All cabinets at ceiling level shall have shall have removable backs, which are screwed, in place for access to harness. Stack cabinets shall have removable panels for wiring and hose access. BACK-UP ALARM A back-up alarm shall be installed and have a momentary disable switch in the driver’s console. If disabled while in reverse, the back-up alarm shall automatically reset when shifted out of reverse. SERVICE LOOP A 6” service loop of wire or harness shall be provided at all electrical components, terminals, and connection points. DRIVER’S CONSOLE The driver’s console shall be manufactured from formed aluminum. The installed console shall include the following switches: Module Disconnect Emergency Master Light Bar-Red Light Bar-White Flasher Flashing Headlights Strobes Blank Blank Opticom Left Scene Right Scene Blank Blank Blank Blank Blank Back-up Disable Other items to be installed in the console are: Voltmeter Combined Door/Compartment Open Warning Light Siren Head SWITCHES Switches shall be the lighted rocker type and be permanently marked by function. One (1) spare switch shall be provided. 25 MAP LIGHT A map light with a 19” flexible neck shall be mounted in the cab area. DOOR AJAR WARNING LIGHT A red flashing warning light on the driver’s console shall be provided to warn the driver of an open passenger access door(s) or open exterior compartment door(s). ATTENDANT CONTROL PANEL The attendant control panel shall be located in the action area. The panel shall include one (1) row of switches, as follows: 1. Dome Hi/Lo 2. Dome Hi/Lo 3. Aspirator 4. Vent 5. Fluorescent 6. Blank A separate climate fan switch and thermostat shall be located adjacent to the attendant control panel. ACTION WALL AREA LIGHTING The entire action area shall be lighted utilizing a Thin-Lite Model 612 light with 12 VDC dual 11” fluorescent bulbs. STEP LIGHTS The side access doorstep well shall have a light installed. MODULE INTERIOR LIGHTING The module interior lighting shall be designed to keep vehicle height to a minimum without interfering with the structural integrity of the roof. The lighting shall consist of eight (8) dual intensity recessed lights – one (1) bank of four (4) lights shall be positioned toward the streetside and one (1) bank of four (4) lights toward the curbside – and two (2) fluorescent lights recessed in the ceiling toward the streetside. There shall be a Hi/Lo/Off switch for each bank of lights and an On/Off switch for the fluorescent lights. All switches shall be automatically activated when the rear or side doors are opened. BASIC EXTERIOR LIGHTING The exterior lighting shall include headlights, parking lights, directional signal lights, tail and stop lights, and clearance lights as required by FMVSS 108. Rear stop, turn, side 26 marker and back-up lights shall be “Truck-Lite” sealed units. Red and amber module clearance lights shall also be “Truck-Lite” sealed lights. COMMUNICATION EQUIPMENT POWER SOURCE An appropriate 12 VDC power point shall be installed in the console area to allow ease of installation of an 800 Mhz radio, and 800 Mhz VRM and a laptop computer. These items shall be installed by the fire department. The exact location and type of power point shall be discussed at the pre-construction conference. ANNTENNA MOUNTS AND CABLES Two (2) NMO universal antenna mounts with KUDPL25 cables shall be installed on the module. The antenna base access shall be through the dome light openings and the cables shall terminate at the driver’s console. The exact location of the antennas and cable routing shall be discussed at the pre-construction conference. BLOCK HEATER A thermostatically controlled block heater shall be installed. The unit shall be wired to the 110VAC shorepower system and be circuit protected. 110 VAC/SHORELINE CIRCUIT BOX The shoreline shall be installed with an ignition cut out that will prevent the vehicle from starting if the shoreline is plugged in. Utility power shall be furnished with 110 VAC shorepower via a 15 amp plug located on the driver’s side of the vehicle and distributed via a formed .125” aluminum power box recessed into the streetside front compartment. The power box shall be flush mounted so as to maximize the compartment space. The box shall have an easily removable cover. The box shall contain three (3) 110 VAC power (outlets, IV warmer, etc.), GFI protected the block heater and battery charger. Two (2) breakers shall be installed, one for protection of the shoreline itself, the other for protection of the block heater receptacle. Four (4) 110 VAC duplex grounded outlets shall be mounted, one (1) in the action area, one (1) in cabinet 17, one behind the driver’s seat, and one in compartment 2. BATTERY GROUNDS In addition to the OEM grounds, the following ground circuits shall be added: 4 ga. Ground cable from the module power component panel to the frame, two (2) braided ground straps from the module body to the chassis to reduce RF interference. 27 BATTERY CHARGER A 30-amp battery charger/conditioner shall be provided and wired to the shoreline. The charger shall have totally filtered output voltage, locked at a maximum 14 volts. The charger shall be designed for long term charger and converter operation without damage to batteries. BATTERY MODIFICATIONS In addition to the two (2) OEM batteries, there shall be two (2) Interstate 31-ECL 700 CCA, 875 CA and 190 minutes each of reserve capacity. The two (2) additional batteries shall be located in the curbside front exterior compartment. The OEM and module batteries shall be interconnected to provide maximum cold cranking amps and reserve capacity at all times. 12 VOLT RECEPTACLES Two (2) 12 volt, 20 amp cigar type receptacles shall be provided one (1) in the curbside front inside/outside compartment and one (1) in the action area. Receptacles shall be powered continuously. COMPARTMENT LIGHTING A 3” dome light shall be installed in all outside compartments and shall be activated by a door switch. EXTERIOR DOOR SWITCHES Exterior door switches shall be Cole Hersee Model 9299, ½” door switches. All door switch terminals shall have heatshrink installed. EMERGENCY WARNING SYSTEMS FRONT LIGHT BAR The front light bar shall be a Whelen 9806W Edge Plus 94” lightbar, with internal strobe power supply. The pattern from curbside to streetside shall be as follows: Red Strobe, Clear Strobe, Red Strobe, Opticom 9592, Red Strobe, Clear Strobe, Red Strobe. The light bar shall be recess mounted with the horizontal plane of the module roof, and protrude no more than ½” beyond the vertical plane of the front and sides of the module. The clearance lights shall be an integral part of the light bar. The Opticom shall be wired through the neutral safety switch. 28 REAR LIGHTBAR The rear light bar shall be a Whelen 9804W Edge Plus 94” light bar, with internal strobe power supply. The pattern from the curbside to the streetside shall be as follows: Red Strobe, 17 Degree Angled Scenelight, Amber Strobe, LED Brake light, Amber Strobe, 17 Degree Angled Scenelight, Red Strobe. The rear doors shall activate the rear scene lights. The light bar shall be recess mounted with the horizontal plane of the roof, and protrude no more than ½” beyond the vertical plane of the rear and sides of the module. The clearance lights shall be an integral part of the light bar. FLASHERS Four (4) fixed Red strobes shall be mounted two (2) on each side of the module in the upper corners. The lights shall be Whelen 901000RU. Two (2) fixed Amber strobes shall be mounted on the rear of the vehicle at window height. The lights shall be Whelen 901000AR. SCENE LIGHTS Four (4) parabolic scene lights, mounted two (2) on each side of module shall be installed. The scene lights shall be flush mounted and have internal optics to deflect the light down at 13 degree angles. The lights shall be Whelen model 90K000YU OptiScene lights. The side door shall activate the curbside scene lights. SPOTLIGHTS A 300,000cp Questar roof mounted spotlight, shall be installed in the center of the cab roof. INTERSECTION LIGHTS Four (4) intersection lights shall be installed, one (1) on each fender and one (1) above each fender wheel well. These lights shall be Whelen 702000RU with 7EFLANGE red strobe intersection lights. HEADLIGHT FLASHER UNIT The headlight flasher unit shall be a Whelen SSF 2150A headlight flasher unit. GRILLE LIGHTS There shall be two (2) Whelen 702000RU Red strobe lights with 7EFLANGE installed in the grille. 29 SIREN The siren shall be a Whelen, minimum 100 watt siren. The unit shall include provision for PA. SIREN SPEAKER The two (2) siren speakers shall be mounted under the front bumper. Each speaker shall have a 100 watt driver. SEQUENTIAL SWITCHING SYSTEM There shall be a Kussmaul sequential switching system installed to control emergency lighting. HALOGEN FLASHER CONTROL A 50 amp per terminal Vanner 1250 GPC flasher shall be provided to control the halogen flashers. SUPPORTING DOCUMENTATION The following shall be provided with the vehicle: Chassis owner information packet. Extra set of keys. Lifetime module warranty. Factory warranty on chassis. 7 year/75,000 mile limited electrical warranty. 2 year/30,000 mile conversion warranty. 5 year paint warranty. Module remount engineering checklist. Climate control information and warranty. Main schematic. Electrical equipment amperage ratings. Wire coding list. Schematics for the standard system(s) (as built) Driver’s switch console Attendant switch console Climate control system Dual battery system Module harness routing Interior and exterior lights Operations manual. 30 Schematics for individual options. Warranty and parts list for light bar, etc. 31