Report of the Inter-Ministerial Task Force on

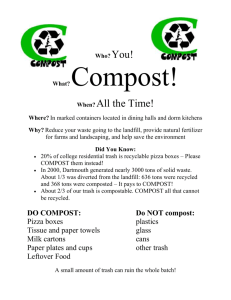

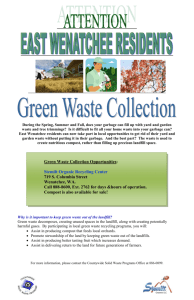

advertisement