The role of interactional expertise in interpreting

advertisement

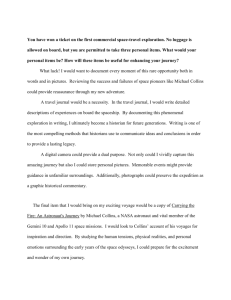

The role of interactional expertise in interpreting: the case of technology transfer in the steel industry Rodrigo Ribeiro Centre for the Study of Knowledge Expertise and Science (KES), School of Social Sciences, Cardiff University, Glamorgan Building, King Edward VII Avenue, Cardiff, CF10 3WT, U.K. RibeiroR@Cardiff.ac.uk Department of Production Engineering, Federal University of Minas Gerais, Rua Engenheiro Senna Freire 612, Belo Horizonte, CEP: 30360-660, Minas Gerais, Brazil RibeiroR@dep.ufmg.br ABSTRACT I analyse the case of three Japanese-Portuguese interpreters who have given support to technology transfer from a steel company in Japan to one in Brazil for more than 30 years. Their job requires them to be ‘interactional experts’ in steel-making. The Japanese-Portuguese interpreters are immersed in more than the language of steelmaking as their job involves a great deal of ‘physical contiguity’ with steel-making practice. Physical contiguity undoubtedly makes the acquisition of interactional expertise easier. This draws attention to the lack of empirical work on the exact way that the physical and the linguistic interact in the acquisition of interactional expertise, or any other kind of expertise. Keywords: interactional expertise, technology transfer, interpreting, physical contiguity, linguistic socialization 1/21 1. Introduction1 The work of the Japanese-Portuguese interpreters described here is part of a 50 yearlong technology transfer between Japanese and Brazilian companies. The interpreters have learned to talk about areas of the steel industry and steel-making process with confidence even though they are unable to contribute to steel-making. Using Collins and Evans’ terminology, the interpreters have acquired ‘interactional expertise’ in steel-making but not ‘contributory expertise’.2 I am going to use the term ‘physical contiguity’ to describe proximity to the practices of a domain that falls short of active involvement or ‘hands on’ experience. For example, in addition to their decades-long mediation in technical discussions of solutions to technical problems, the interpreters witnessed the assembly of machines and plant start-ups and watched as tests were made and tolerances were adjusted. ‘Physical contiguity’ stands between purely ‘linguistic socialization’ and ‘physical immersion’ – the latter meaning ‘hands on experience.’3 The case seems to show that even when someone is exposed to the physical practices of a domain in every way short of hands-on involvement their resulting expertise is still interactional rather than contributory. Physical contiguity does, however, facilitate the development of the specialized language. This draws attention to the fact that most of the cases of acquisition of interactional expertise discussed in the literature do rely on physical contiguity as well as linguistic socialization. Though the idea that interactional 1 I am grateful to Harry Collins – both as my supervisor and the Editor of the Special Issue – for the hard time he gave me in respect of earlier drafts of this paper. The paper also benefited from the comments of the external and internal referees, Robert Crease and Rob Evans, and of the participants of the KES meetings. I am also indebted to the Japanese-Portuguese Interpreters, who kindly accepted to share their lives and professional experiences with me, and to Sara Delamont for helping me with the translations from Portuguese into English. This research was funded by CAPES Foundation, Brazil and received financial support from the Brazilian Company for the fieldwork. Any person or institution that publishes anything that mentions, discusses, broadens or contradicts the content of this paper, is kindly requested to send me the references in order to make the process of discussion and generation of knowledge dynamic, thus offering contributions and increasing the opportunities for the growth of the parties involved and/or related areas of knowledge. 2 See Collins and Evans (2002). 3 See, respectively, Collins (2004a: 127) and Collins and Evans (2007: 61). 2/21 expertise is in principle attainable through linguistic socialisation alone is useful for describing the underlying concept, it remains to establish the point empirically. I start by describing Collins and Evans’ typology of expertises and how they are acquired.4 I then outline the nature of steel industry technology, the history of cooperation between the Japanese and Brazilian companies, and the job of the interpreters. The way the interpreters acquired interactional expertise is then analyzed. 2. Types of expertise and their acquisition The five types of specialist expertise described by Collins and Evans can be divided into two groups. The first group comprises the three cases – ‘beer-mat knowledge’, ‘popular understanding’ and ‘primary source knowledge’ – in which one would acquire the knowledge of a specialist domain without interacting with its practitioners. This is achieved through the use of ubiquitous expertises, such as ‘reading or listening’5. In contrast, the only way to develop the remaining two highest levels of expertise is immersion in the culture of full-blown practitioners. This immersion is divided into two types: ‘linguistic socialization’ and ‘physical immersion’.6 ‘Linguistic socialization’ leads to interactional expertise, defined as ‘the ability to master the language of a specialist domain in the absence of practical competence’. ‘Physical immersion’, on the other hand, leads to contributory expertise, which is ‘what you need to do an activity with competence’.7 Collins argues that the reason why ‘interactional expertise’ has been neglected for so long is the polarity created between ‘formalists’ and ‘informalists’.8 The latter took the extreme position that one could only master a language through full immersion in ‘the entire form-of-life of a domain [i.e. which includes practice]’ in order to deny the ‘formalist’ view of 4 This typology was first introduced in Collins and Evans (2004), and is dealt in detail in Collins and Evans (2007). Henceforward, when I refer simply to ‘Collins and Evans’ with no date it will imply Collins and Evans (2004, 2007). 5 See Collins and Evans (2007: 19). ‘Popular understanding’, for instance, ‘can be gained by gathering information about a scientific field from the mass media and popular books’ (Collins and Evans, 2004: 7). These types of expertise are not the focus here. 6 7 8 See, respectively, Collins (2004a: 127) and Collins and Evans (2007: 61). See Collins and Evans (2007: 16) for the definition of both concepts. See Collins (2004a). 3/21 language as sets of propositions. 9 The mistake of the informalists was to think that only practice would allow one to acquire the tacit knowledge needed to speak the language of a domain. It is now argued that one can acquire the tacit knowledge of a specialist language without the practice.10 Nevertheless, ‘linguistic socialisation is very far from feeding with discrete propositions; the language learned as a result of linguistic socialisation is as loaded with tacit knowledge, Wittgensteinian rules, and ability to make intuitive judgments, as any native language’.11 In practice, as already mentioned, interactional expertise is usually acquired through more than purely linguistic socialisation. I will illustrate the role of physical contiguity to the steel-making process in the development of the interpreters’ competences. First, however, we need some popular understanding of the areas of steel-making under discussion and some beer-mat knowledge of the interpreters’ backgrounds. 3. The steel industry: areas and technology12 Figure 1 illustrates the three main operational areas of an integrated steelworks: reduction, steelmaking, and rolling. In the reduction process, coke and sinter (suitably prepared ore) are reduced in the blast furnace to unrefined pig iron. In the steelmaking plant, the pig iron is further refined and mixed with other materials depending on the type and grade of steel desired which varies according to application. For example, steels used for making the outside panels of automobiles must have good formability and generally lower mechanical resistance than steel used in structural parts; for the latter impact and fatigue resistance are more important than formability. In the steelmaking area the two main pieces of equipment are the converter, where the pig iron is transformed into steel by removing some of the carbon and introducing other additives, and the slab caster, which produces slabs from molten steel. The slabs that come from the casting plant then enter hot rolling mill, following different paths. For instance, if the client is the ship industry, the slabs go to the heavy 9 See Collins (2004a: 126). As Collins (2004a: 126) explains the argument, ‘“Those formalists”, we [the informalists] say, “mistakenly think that you can strip knowledge out of experts’ heads and encodify it in propositions’. 10 See Collins and Evans (2002) and Collins (2004a). 11 See Collins and Evans (2007: 88-89). 12 I am grateful to a specialist – who preferred to be anonymized – for help with technical details. 4/21 plate mill whereas in the case of the automobile industry the slabs go to the hot strip mill (e.g. for wheels) or to the cold rolling mill (e.g. for automotive panels). Figure 1 – An overview of the steel production and some of its final applications 13 The quality of a steel depends on both its chemical composition and the way it is processed -- finishing temperature, cooling rate, coiling temperature and so forth. The Department of Metallurgy is responsible for quality design at the Brazilian Company with additional studies undertaken by the Research and Development Department (R&D). Thus, metallurgy and R&D are the two areas which require the broadest and deepest technical understanding. 4. The setting of the interpreters’ work, the fieldwork and the research subjects The history of technology transfer between the Brazilian and Japanese companies began with a nine-year period (1957-1966) in which various Japanese specialists 13 This description is based on the Brazilian steelworks, but does not cover all of its production lines, equipment, final products and applications. 5/21 designed the Brazilian steelworks, manufactured its main equipment, and gave technical support during its construction and start-up.14 They then ran its commercial operation for five years before handing over to the Brazilians. The period 1966-to date is characterized by paid contracts for technology transfer. These include technical support in Brazil and training in Japan. The first such agreement was signed just after the Brazilian engineers began to manage the steelworks’ operations (1966) and lasted for approximately 10 years. Since then, as each contract ended a new one has been put in place. The last one was signed in 2004 and is expected to finish in April 2009. The first nine-year period saw a total of 241,080 man-days of Japanese technical assistance provided to Brazil, while, up to 2003, the second, post-1966, period called for 33,829 man-days.15 From the beginning communication between the Japanese specialists and Brazilians has been facilitated by Japanese immigrants and Nisei (children of immigrants) hired by the Brazilian company. Although some of the immigrants and Nisei were engineers, the majority did not have a degree. They either started to work as interpreters or as operators, foremen, or clerical assistants. In 2004, I conducted lengthy interviews in Brazil with three of the interpreters (J, B and JB). None of these had any experience or knowledge of the steel industry before being hired to work in the Brazilian plant. Each worked in administrative areas before or in the middle of their careers as interpreters.16 For each case, Table 1 shows the period they worked as clerical staff and as an interpreter. J learned Japanese by living and studying in Japan whereas B and JB were brought up in Japanese families belonging to Japanese colonies in Brazil. They all learned Portuguese by living in Brazil, while B and JB also went to Portuguesemedium schools. IDENTITY PERIOD AS CLERICAL STAFF PERIOD AS INTERPRETER J 4 years 38 years B 6 years 29 years 14 Most of this description is based on Ribeiro (2003). 15 Excluding training carried out in Japan. 16 None of the clerical work undertaken by the interpreters enabled them to gain contributory expertise in the areas they interpret for. 6/21 JB 5 years 24 years Table 1: Experience of interpreters discussed in this paper (up to 2004) When J was hired in May 1962, he knew neither Portuguese nor the steel industry. His first task was to classify the Japanese designs of the blast furnace plant – which was still under construction. Meanwhile, workers were hired for the operation of the blast furnace which was about to begin operations. Subsequently, J was assigned to translate all the material (e.g. standards and manuals) for the training of the Brazilian operators in regard to the blast furnace operation. Working with the designs was the first part of J’s familiarisation with the Japanese technical terms for the equipment and with some of the processes involved in the production of pig iron. All the queries he had were initially answered by Japanese specialists. The process of translation then began to familiarise J with Portuguese. For instance, all the translated material was checked by the Brazilian engineers. Their many revisions and correction helped J to start learning what we might call ‘blast furnace Portuguese’ along with something about the functioning and operation of the plant. Nevertheless, J felt that this was not enough and asked the Japanese specialists to lend him technical books. These books were written in Japanese and discussion related to them was again carried out with the Japanese specialists. In addition to this, by the end of the first technology transfer period, J had witnessed the construction and start-up of two blast furnace plants which provided him with a rare opportunity to increase his technical understanding. He said that at the end of this period: ‘with some exaggeration, even closing my eyes, I knew [what was going on]. This knowledge of the area facilitated future interpreting a lot’. From 1967 to 1975, J worked as an interpreter for the Japanese technical advisers that were coming to the blast furnace plant in accordance with the technology transfer contracts characteristic of the second period.17 During the first ten-year technology transfer contract the Japanese group comprised eight specialists who were rotated every six months.18 For eight years, J and another interpreter were the means 17 Before that, J worked 1.5 years writing up reports for material and production control in the blast furnace. He referred to this as an ‘administrative [job]’, a ‘simple routine’, which did not help in his future role as interpreter. 18 The period of stay of the Japanese groups in Brazil changed with time. 7/21 by which the Japanese advisers and Brazilians could communicate with each other in order to solve technical problems and discuss improvements in the blast furnace. In 1976, J became the coordinator of the `Group of Interpreters’ of the Brazilian Company. As the coordinator, he began to interpret in the much more difficult field of metallurgy. Since then, he has interpreted and translated for all areas of the steelworks, including the administrative ones. B has a similar history to Interpreter J. Hired in 1969, B worked as a member of the clerical staff in the Inspection Certificate Sector of the Brazilian Company for nearly 6 years, before becoming an interpreter. He was in charge of typing the results of the mechanical and metallographic tests on each batch of steel into a certificate intended for a specific client. Punching keys on a typewriter was a mechanical job but it introduced him to the steel industry. For instance, when first reading an inspection certificate, B could not understand the meaning of terms such as ‘yield point’ and ‘tensile strength’. Fortunately B’s office was in the same building as the testing laboratories: ‘it was close and I had colleagues over there … sometimes, working on the night shift … [you] feel sleepy, then I went there … to see what they were doing, to talk to them, to see the tests’ (Interpreter). The experience of watching and talking led B to begin to understand that international standards meant that each type and grade of steel must have certain mechanical properties which are measured by its physical parameters.19 The quality of a type/grade of steel is, then, given by the range of values within which the results of the laboratory tests for pre-specified physical parameters must fall. All this knowledge has proved to be relevant when B came to work as an interpreter: ‘This [experience at the Inspection Certificate Sector] has helped me to enjoy the metallurgical side [of the steel industry]. Discussion about quality, quality design. When you talk about quality design this is very much part of it; this issue of mechanical properties. It is the foundation. So, when someone says ‘mechanical property’ [in the technology transfer meetings], as I have this knowledge, it facilitates a lot. When [they] say [about] a quality, it comes [to 19 For instance, the Interstitial Free Steel (IF Steel) parameters are: steel yield strength, tensile strength, elongation, Lankford Coefficient, planar anisotropy and hardening coefficient (Pereira and Meyer, 2003). 8/21 my mind] oh, this quality, isn’t it? I already know, say, the tensile strength, yield point… [It was all] about these parameters, that I already knew. In 1975, B was transferred to the Group of Interpreters. For one-and-a-half years B supported the Japanese advisers and the Brazilians in charge of the construction and start-up of the conventional casting (which differs from the current practice), the converter belonging to Steelmaking Plant II, and the plate mill. There was one interpreter for each adviser in the conventional casting and in the plate mill, and one to two in the steel-making plant, so B established a very close relationship with the Japanese advisers. His interpreting work led B to learn some of the Japanese technical terms and their counterpart in Portuguese simultaneously with increasing his technical knowledge. B continued to give support to these plants for approximately six months. By the end of 1977, B was sent to interpret in the area of instrumentation and, since then, he has also supported technology transfer in all the areas of the steelworks.20 JB’s professional history differs from the others’ insofar as he started out working as an interpreter. Nevertheless, he had no previous knowledge of the industry: ‘both the Japanese and Portuguese [steel industry languages] were German for me’. Hired in 1975, JB first supported Japanese advisers in the electrical part of the steelmaking plant. For one and a half years, he had the chance to witness the start-up of the continuous casting machine and also translated some material in the area of electrics; problems were solved by Brazilian engineers or Japanese advisers. JB then worked in the coke plant from 1977 to 1979, which called for learning about another area: ‘I was working with electrics and then I was sent to work with refractory. I knew nothing … then, it started all over again [long suffering tone].’ In the following five years JB worked in the Group of Interpreters, when he had the chance to interpret for the areas of steelmaking, coke, blast furnace, cold and hot rolling mills and forging. 20 An interesting aspect of B’s language proficiency is that his knowledge of Japanese is mostly oral. As he was not educated in Japanese, he cannot read day-by-day Japanese fluently and finds it very difficult when asked to translate written Japanese into Portuguese. Things are better when B is to translate within the technical sub-set of Japanese he is used to. In the areas he is not acquainted with, he first translates word by word and then tries to make sense of it which, he says, is very difficult: ‘perhaps I can even read, but I will not understand, as it happens with anyone who does not understand a field [about which he or she is reading]’. 9/21 A break in JB’s career happened from 1984 to 1989, when he worked in the administrative area of the cold rolling mill. JB’s desk was in the room where the Technical Unit of the plant was located. This enabled him to listen to many technical discussions in regard to product defects, production problems, and the attempts to solve them. During his free time, JB used to go to the shop floor in order to understand the processes and the problems he had heard about. Problems were taken up with the operators, foremen, or the Technical Unit engineers. As a result of this experience, the cold rolling mill plant is the area in which JB feels most comfortable when interpreting. In 1985, JB returned to the Group of Interpreters and continued to interpret for all the areas of the Brazilian steelworks. My account is based on interviews with the three interpreters but all the quotations are taken from the account of Interpreter B because he provided the most detailed and complete account of his work and its demands. Similar views were provided by J and JB but they were more dispersed throughout the interviews. Nevertheless, many of the issues raised by B – such as the importance of witnessing plant start-ups – can be found in J and JB’s biographies. The overall points made here are also backed up by the many interviews I conducted in the wider study of which this is a part. The empirical points of the paper were reconfirmed by a respondent validation with interpreters J and B – JB had retired and moved to Japan – as well as with other two interpreters of the Brazilian Company who do the same work. After reading aloud all the sections with the empirical findings and discussions, I asked for their assessment. The four interpreters unanimously agreed that the account faithfully represents their experience. 5. A closer look at the development and role of interactional expertise The interpreters say that the first thing they must learn are the ‘technical terms’, for equipment, processes, and activities. Knowing the names for things is not enough for the purposes of interpreting, however. To interpret, the meaning of terms has also to be understood; the purpose of the equipment, the processes, and the way they are interconnected must be grasped. Thus the interpreters are particularly happy about an occasion when they were invited by a Brazilian engineer to attend a technical seminar in one of the operational plants. They thought this type of invitation should be the rule. On the other hand, all three interpreters have gone through the experience of hearing 10/21 some of the participants at meetings tell them that: ‘you do not have to understand what I am talking about, just to interpret’. Interpreter B explained: ‘I cannot translate that which I cannot understand. [Our main role] is to make it possible for each side to communicate with each other. We are in the middle. This is what an interpreter is for. Otherwise there would be no need [for interpreters with technical knowledge].’ B added that an interpreter without technical knowledge would be as bad as no interpreter at all: ‘they might as well [be left to] talk to each other directly [in their own languages], and neither would understand anything anyway [laughter].’ Watching and interpreting as the machinery for the plant was first assembled and then watching and interpreting during the start-up period proved of immense value for B in gaining technical understanding and fluency. As the interpreter explains, the start-up period provides the opportunity to learn new things alongside the new operators, who are also learning. ‘The best thing is to witness the beginning of operations, the assembly … We learn a lot. … We see the equipment, see how it works. [We] watch the beginning of the operations, the adjustment of the equipment. We get to know the equipment, the operations, almost from the first steps, the A, B, C. … Thus we learn. Why? The operators are also starting. So, it is easy to understand as well. [You] start with the basics and keep improving. And see the equipment very closely. ... Let’s say... there is a problem with a machine. Then we have to be inside, to go inside the machine. Once [the machine is] in operation you do not have access to it. … [In addition] problems happen more often at the beginning, thus [we have] more opportunities, opportunities of really getting there, there inside, don’t we? To solve the problems. ...’ To understand how machines work facilitates, in turn, the understanding of some practices of the domain. In what follows, B describes how entering inside a continuous casting machine (indicated by the dashed lozenge in Figure 1 and enlarged in Figure 2), helped him to understand some tasks related to the machine set-up. ‘We talk[ed] about [the importance of the] start-up because, for instance, machinery for continuous casting. … At that time, alignment, spacing between 11/21 the rolls, it was done manually, [the worker] had to go inside the machine.21 So, I went inside the machine with the foreman. This helps you to see how it is inside, how things work inside. Why the rolls must be very well adjusted, how you adjust a roller. Spacing, alignment, how this is done. Because if you do not know, if you have never seen [how it is done], [the participants in the technical meetings] simply say “to change the spacing”. At the moment [of interpreting], you say ‘spacing’, ‘alignment’, but you… it does not come to your mind … this image. How this is done, what it means, how important it is.’ Figure 2 – Schematic drawing of a continuous casting machine showing the rolls that guide the steel as the slab is formed Interpreter B went on, showing the link between understanding the practices of the domain and learning the specialist language: ‘As I said about entering the machine. I entered with the foreman, following the operator who does the adjustment, following the Japanese adviser who was giving the instructions – to interpret the instructions. But I have never done the 21 ‘Roll’ is a technical term of the steel industry; in common English usage the term would be `roller.’ 12/21 spacing alignment, ‘hands on’ experience, as they say. I watched the guy doing it, [assessing] the instructions, how it should be done…’ Ribeiro: What specific aspects of the experience inside the machine are important [for interpreting in technical areas]? ‘Because then, later on, when we discuss the alignment standard or spacing standard … when someone says ‘Look, you have to align with tolerance of zero point something’… I can see in my mind’s eye the image of how this alignment should be performed, which tools are going to be used, the importance of the job, why he has to do it, the difficulties [of doing it]… If you only know [about alignment] in theory, [if you have] never seen it done … [For instance] the person says ‘alignment’, but what kind of alignment? … There are many types of alignment. To align a railway track, to align a wall (laughs). It is very different. So, when you know the process, have seen and know [the phenomena], [the] ‘alignment’ already comes to your mind. It is that alignment. … [You] know what it is about. So, you are not, as I always say, lost in the conversation. … It is not that I will … give tips [in technical meetings]. But [the fact is that] I am participating in the conversation, I know what it is about. Then, it is much easier for us to interpret.’ (stress added) In discussing this matter further, I asked B what he thought he would have missed if he had not had the experience of seeing the alignment process. ‘OK. Well, first, theoretically, I would not know, [I] would not even have an idea of what this would be. [It would be] simply a word, in certain ways, even a vague word for me. Because I would not know – I would not know what this is. [I] cannot even imagine.’ I pressed him further saying that a teacher would then explain how alignment works and would even show some drawings: ‘Yes, but it does not give an idea. … [you] can make a drawing but you do not… You will have a vague knowledge, you will imagine. Imagine. Only imagine.’ Interpreter J mentioned other ‘common words’, which they would have difficulty understanding and interpreting without technical knowledge. For instance, ‘liner’ is a plate which is used to avoid wear and tear, but when participants say it, the 13/21 question is ‘which liner’, in which equipment? The same applies to ‘standard’, ‘pattern’, ‘control’, and ‘design.’ Witnessing the history of technology implementation, improvements, and development also added to the interpreters’ technical understanding. ‘In the beginning [of operations] there is always – generally – more problems … it is through problems that we learn (laughs) … It happens many times that the design has ... to be partially changed ... “No, this part is really not good. I must modify [it]”. Sometimes [someone] sees it [the part] but sees it already modified. Now, why did it have to be modified? We got to know. [If you had not seen it modified you would not] know [that] there was this problem.’ Indeed, knowledge of technological evolution even put the interactional experts in a position to retrieve information about past events. Ribeiro: When you deal with novices [from the Brazilian company] … do you add information to what the Japanese has said in order to explain better? ‘Sometimes … For instance, if it is [something to do with] the company’s history. A novice sometimes knows nothing. I believe I have this knowledge ...’ Ribeiro: And how about the technical part? Does it happen that you say “no, what he [the Japanese adviser] is [really] talking is about such and such equipment [not what you think]”? ‘Yes, yes, I say [that].’ I asked the interpreter to discuss the times when he adds technical content to what the Japanese expert has said and when he might do this. ‘When I am sure [about it] (laughs). … [For instance], it happens that the Japanese talk about a piece of equipment that the guy has not had the opportunity to see … Or even one that was used in the past and does not exist any more, but that was important for the evolution, for the development until the current equipment evolved, for instance.’ 14/21 Finally, the knowledge that sustains the interpreters’ interactional expertise helps to smooth technical interactions. ‘Sometimes [the participants of the meetings] forget that there is an interpreter [and talk uninterruptedly] (laughs). ... [Then it is important] to know the subject – to have [at least] a notion. Why? The two are specialists. We stand between two specialists. … [When] we have the knowledge we can enable them to talk between themselves as if they were talking [directly] to each other. There is no need [for them] to explain the subject or to speak in a simpler way, as if they were talking to a lay person. … I will be able to transmit what [one] guy is talking to the other because I understand ... So, for sure, when we master a subject, we gain speed and efficiency in interpreting. If I do not … understand, the guy will say something and I will ask: ‘What is that? [I will have to ask him to] explain what it is so I can transmit it. [This is] because, if I am to interpret word by word, it does not make sense sometimes. It can even … backfire.’ We can contrast the cases where technical interpretation does work with ones where it is more difficult. These occur when the interpreters do not have the technical knowledge and, consequently, fluency in the (specialist) language – interactional expertise. One example is interpreting in meetings that deal with technology transfer in regard to environmental laws. B says that Japanese and Brazilian laws are complex and there are some very specific terms. Unlikely the operational areas, there is a lot of room for different interpretations, which impairs his ability to do good work. ‘There are nuances that we cannot notice .... Nuances inside the phrase. The phrase is so subtle that I cannot interpret properly. [I cannot] understand. Understand what that phrase really means. It is not like mathematics in which two plus two are four … [In law] there is a margin for two plus two to be five. … [When we] go to a piece of equipment and the guy says “it is this”, that’s it. There is no way that other [guy] will arrive and think that it is not. “No, it is not like that, it is this way”. There is only one way. [But in] these [environmental] regulations, these terms, there are a lot of things that give a margin for interpretation … Now, who has written [it], with what purpose, what thought [lies behind it], [I] do not [know].’ 15/21 The problem is that the ‘operational’ areas are also very complex, also have a lot of specific terms, and the technical language is certainly amenable to different interpretations. For instance, B could narrow down the possible uses of ‘alignment’ because of his technical knowledge. The same is true in regard to his understanding of the ‘purpose’ of ‘spacing’ and how it was done. Interestingly, as we see, the importance of understanding for interpreting in technical areas is forgotten by the interpreter when he offers his explanation of the problems thrown up by the field of law. The interpreter then talks of language as something abstract, not something the meaning of which can be understood only by understanding the practice which it describes.22 The interpreter says: ‘Perhaps [my difficulty in interpreting in the field of law] is due to the deficiency in my Portuguese – of my knowledge of the Portuguese language itself – of the terms’ – even though the interpreter knows well that more knowledge of Portuguese would not solve a problem of interpreting in a technical area.23 What seems to be going on here is that the interpreter is `buying in’ to the formal model of language as described in the beginning of this paper. The interpreter knows from his technical interpreting experience that the formal model of language does not work but falls back on the model to explain his deficiencies in the field of law. This shows the grip that the formal model has on our imaginations when we are not reflecting carefully on either our practice or on a philosophical analysis of what it is to know a language. The interpreters also placed a lot of emphasis on being able to see the things which they had to discuss in the course of interpretation.24 ‘Exactly [I can recollect what was said in the areas I know]. Why? It seems a joke, but there are two entrances and one exit. Things can enter here [pointing to 22 Talking about the introduction of a new concept in a specialist language – the medical language – Winch (1995 [1958]: 123) points out that ‘To give an account of the meaning of a word is to describe how it is used; and to describe how it is used is to describe the social intercourse into which it enters’. 23 JB said that there were few occasions in which the Japanese advisers were unwilling to repeat and explain what they had just said. They ordered him to pass on what he had heard, as if interpreting was just a problem of vocabulary or dictionary-type of knowledge. 24 Schilhab (2008 – this volume) argues that in some cases the human brain treats the experiences of seeing and practicing similarly. 16/21 his eyes] or here [pointing to his ears]. What enters here [through the eyes] does not go out here [pointing to his mouth but is retained]. What enters here [through the ears] gets out here [mouth and is lost – laughter]. What enters through [the eyes] stays in the mind.’ They found it harder to learn to interpret in areas where there was nothing to see such as informatics, electrical maintenance, and research. But, as they do interpret in these areas, I probed B on this issue and he said that in such cases he found it harder to memorize and he forgot what he had learned much quicker. ‘Isn’t there that Japanese saying? “It is better to see once than hear one hundred times”.’25 6. Conclusion The case of the Japanese-Portuguese interpreters demonstrates that to learn a specialist language means learning more than words; it means learning interactional expertise. Technical knowledge and specialist language fluency – interactional expertise – are intertwined and change in concert as experience grows. Thus, abstract utterances that meant nothing at the beginning of the immersion start to gain their full significance as time goes by: ‘When I give support to those who research physical metallurgy, something more profound [is going on], it is very complicated (laughs). Then [things] change, the concepts also change according to the experience that we keep on acquiring.’26 The case also shows, if it was not obvious, that the acquisition of interactional expertise is helped by having as much experience as possible of the physical activities and materials and processes of the domain. It is in fact the case that even though the principle of interactional expertise has been expounded in terms of immersion solely in the language, in every case described, except perhaps that of Madeleine, a considerable degree of physical contiguity was involved.27 Even in the case of Madeleine, Selinger as well as Selinger and Mix argue that more physical involvement 25 There may, however, be people who are especially good at thinking abstractly and who would find it less of a disadvantage to learn through immersion in the discourse without actually seeing anything going on. 26 This point is also present in Shrager’s description of how he became a molecular biologist (2008 – this volume, diary entry 20000709). 27 I have in mind the cases described in Collins (2004a), Collins, Evans, Ribeiro and Hall (2006), and Collins and Evans (2007). The case of Madeleine is first discussed in Collins (2004a). 17/21 was involved than Collins implies.28 Physical contiguity is also present in some recently described analyses which turn on interactional expertise such as learning about tuna fishing, becoming an AIDS activist, knowing each other’s sub-fields in gravitational wave physics and other sciences.29 There is still much interesting work to be done exploring just how much physical contiguity aids the acquisition of interactional expertise and, indeed, whether the principle of mastering a language through linguistic immersion alone corresponds to anything that could be achieved in practice. Of course, since in almost every practical situation one could imagine a degree of physical contiguity will be sought out since it makes life so much easier, the question of principle is more one of philosophical than practical interest – a philosophical interest that does, however, bear upon the question of the necessity of the embodiment of computers.30 On the other hand, the case of the pre-lingually deaf clearly shows that physical contiguity, or even full physical immersion in a domain, cannot produce linguistic fluency in the absence of linguistic socialization.31 The Japanese-Portuguese interpreters were maximally linguistically socialized as well as experiencing a great deal of physical contiguity with their subject – short of full-blown hands-on experience. None of them became contributory experts, however – they remained interactional experts at best. On the other hand, it is the very fact that the interpreters are interactional experts that enables them to enhance and smooth knowledge transfer between steel industry specialists. 28 The ‘embodiment debate’ in regard to interactional expertise started with Collins (2004a), followed by Selinger and Mix’s critique (2004) and Collins’ (2004b) answer to that. Another round is found in Selinger, Dreyfus, and Collins (2008 – this volume). 29 The first of the following four cases are described by Jenkins (2008 – this volume), while the remaining – including the AIDS activists (Epstein, 1995) – are taken as examples of the workings of interactional experts by Collins, Evans and Gorman (2008 – this volume). 30 See Dreyfus (1996), Collins (1996, 2000). 31 See Collins (2004a). 18/21 References Collins, Harry (1996). Embedded or Embodied? A review of Hubert Dreyfus ‘What Computers Still Can’t Do’. Artificial Intelligence, 80, 99-117. Collins, Harry (2000). Four Kinds of Knowledge, Two (or Maybe Three) Kinds of Embodiment, and the Question of Artificial Intelligence. In Jeff Malpas and Mark A. Wrathall (eds.), Heidegger, Coping, and Cognitive Science: Essays in Honour of Hubert L. Dreyfus, vol.2 (pp. 163-197). Mass: MIT Press. Collins, Harry (2004a). Interactional Expertise as Third kind of knowledge. Phenomenology and the Cognitive Sciences, 3, 125-143. Collins, Harry (2004b). The Trouble with Madeleine; Response to E. Selinger and J. Mix. Phenomenology and the Cognitive Sciences, 3, 165-170. Collins, Harry and Evans, Robert (2002). The Third Wave of Science Studies: Studies of Expertise and Experience. Social Studies of Science, 32 (2), 235-296. Collins, Harry and Evans, Robert (2004). The Periodic Table of Expertises. [WWW] <URL: http://www.cardiff.ac.uk/schoolsanddivisions/academicschools/socsi/staff/acad/col lins/expertise/index.html > [Accessed 6 February 2007] Collins, Harry and Evans, Robert (2007). Expertise: A New Analysis. Chicago: Chicago Press. Collins, Harry; Evans, Robert; Ribeiro, Rodrigo; and Hall, Martin (2006). Experiments with Interactional Expertise. Studies in History and Philosophy of Science, 37A (4), 656-674. 19/21 Collins, Harry; Evans, Robert; Gorman, Mike (2008). Trading Zones and Interactional Expertise. Studies in History and Philosophy of Science, Special Issue on ‘Case Studies of Expertise and Experience’ (March). Dreyfus, Hubert L. (1996). Response to my critics. Artificial Intelligence, 80, 171191. Epstein, Steven (1995). The Construction of Lay Expertise: AIDS activism and the forging of credibility in the reform of clinical trials. Science, Technology & Human Values, 20 (4), 408-37. Jenkins, Lekelia (2008). Bycatch: Interactional Expertise, Dolphins and the U.S. Tuna Fishery. Studies in History and Philosophy of Science, Special Issue on ‘Case Studies of Expertise and Experience’ (March). Pereira, João F. B.; Meyer, Luiz C. de O. (2003). Present Situation and Perspectives of IF Steels in Brazil. In: Proceedings of the International Forum for the Properties and Application of IF Steels. Tokyo, Japan. Ribeiro, Rodrigo (2003). Technology Transfer and Technological Development: The Case of Usiminas and Nippon Steel Corporation (research report). Belo Horizonte: Department of Production Engineering, Universidade Federal de Minas Gerais, Brazil. Schilhab, Theresa S. S. (2008). Interactional Expertise Through the Lokking Glass: A Peek at Mirror Neurons. Studies in History and Philosophy of Science, Special Issue on ‘Case Studies of Expertise and Experience’ (March). Selinger, Evan and Mix, John (2004). On interactional expertise: Pragmatic and ontological considerations; Response to H. M. Collins. Phenomenology and the Cognitive Sciences, 3, 145-163. 20/21 Selinger, Evan; Dreyfus, Hubert; Collins, Harry (2008). Embodiment and Interactional Expertise. Studies in History and Philosophy of Science, Special Issue on ‘Case Studies of Expertise and Experience’ (March). Shrager, Jeff (2008). The Evolution of BioBike: Community Adaptation of a Biocomputing Plataform. Studies in History and Philosophy of Science, Special Issue on ‘Case Studies of Expertise and Experience’ (March). Winch, Peter (1995 [1958]). The Idea of a Social Science and its Relation to Philosophy. London: Routledge. 21/21