Business

advertisement

Business - plan

The title of the project:

« Construction of small capacity Refinery in Altai krai »

The author of the project:

The Limited Liability Company «Geodesic and Engineering Centre »

THE CONTENT

1. Introduction … … … … … … … … … … … … … … … ….3

2. Technological features of oil refining processes in unit … .... 4

3. Configuration of the unit and placement … … … … … … 7

4. Automation, power supply, analytical supervisory control… 7

5. Ecological aspects of unit operation … … … … …........ …. . 8

6. Basic characteristics of the Refiner and products of raw material

processing … … … … … … … … … … … … … ….. … … … 9

7. Economic indexes of small capacity refinery

… … … … … … … … … … … … … … … … … … … … … … 11

8. Financial plan … … … … … … … … … … … … … … … …12

2

1. Introduction

The problem of provision to remote regions of Russia by high-quality petrol up to real time is

deciding basically by expensive seasonal delivery. Even if this areas have petrol, the oil refining on

regional Refinery does not find wide application and is carried out in limited quantity on the units

which as a rule not provide necessary quality of marketable products, depth of a thorough revision,

and also ecological and technological safety.

The energy strategy of Russia for the period up to 2020 years, affirmed by the order of

Government of the Russian Federation from 28.08.2003г. № 1234-р (section VI-2), implies the

construction of new high performance Refinery of an average power in areas of concentrated

consumption of oil, and in remote northern and eastern areas - small plants with a complete cycle of

oil refining.

For small Refinery the traditional schemas of oil refining used at the large oil refining

enterprises are unacceptable because of the high cost price of processes. That’s why the majority

existing units power up only an atmospheric petrol distillation at which 40-60 % of final - products

are made with fuel oil. Thus receiving of documentary benzenes and diesels is based on

compounding of distillate fractions.

In a base of the unit offered by us is incorporate advanced achievements of the Russian

scientists in sphere of refining hydrocarbon raw material, permitting to finish depth of refining with

90-93 %.

The base of the process consists of atmospheric distillation and combining a viscosity breaking

with cavitation - acoustic influence (the developer is the Limited Liability Company

SCIENTIFIC AND PRODUCTION CENTER " THERMAKAT ", Ufa).

The technology offered by “THERMAKAT" allows to bring up process of refining

hydrocarbon raw material on Refinery up to high-quality products, and also increases output of

refined oils by 20-25 % to compare it with classical methods.

The high performance schema of refining raw material ensures also high profitability of

manufacture, and low payback time of investments. For a unit by productivity 100 thousand tons

per year on raw material payback time is less than 1 year.

3

2. Technological features of oil refining processes in unit.

The process of transformation of hydrocarbonic raw material (oil) to the final-products can be

presented in two stages (blocks):

- Atmospheric distillation of raw material with reception of once-run benzene, diesel fuel and

black oil;

- Processing black oil using "THERMOKAT" technology and receiving additional quantity

of light fractions (once-run benzene, diesel fuel) and bitumen or boiler fuel.

In the considered unit atmospheric distillation of raw material is carried out according to the

traditional, classical technology. Thus there is a possibility of various design columns, furnaces,

heat exchangers, separators and other units depending on production potentialities, used materials,

etc.

The difference from the classical variant is that the rectification column should "process"

gaseous products not only of its own block, but also block "THERMOKAT". Using it in separate

columns their number in installation unfairly increases.

The following block (stage) of processing realizes "VISBRAKING-THERMOKAT"

technology.

"VISBRAKING-THERMOKAT" technology is based on the traditional thermolysis of

hydrocarbons which is combined with several stages of destructive - polycondensation

transformation of hydrocarbons adjustable in time with step changing of pressure and temperatures

under the influence of supersonic fields raised by cavitation devices.

This influence allows providing a special-purpose designation of process (increase yield of

refined oils) by realization of rational decomposition temperatures and exceptions of coke

production, resulting, at the same time, to necessary condensation of heavy hydrocarbons up to the

stage of the asphaltenes which is necessary for recieving oxidated asphalts of adjustable quality.

The use of control energy of cavitation at this or that stage of the process expands the

opportunity of regulation of depth and speed of pass of splitting and condensation reactions,

processes of evaporation and polyfunctional condensation and, hence, a yield and quality of

products.

The process is made for recieving hydrocarbonaceous distillates and residual products (fuel

oils and bitumens) from heavy oil residue, including black oils, petroslimes, gas condensate

oddments, by soft controll thermal cracking in conditions of cavitation - acoustic influence on

reactionary environments.

Hydrocarbonaceous gas in quantity 2-5 % is used for technological needs, from 65-88 % of

distillate fractions components produce the engine fuels or furnace fuel (light) are manufactured, and

6-30 % of residual products are qualified as road or structural bitumens.

Finishing of received once-run benzine (octane value 50-60) up to a commodity output is

possible in various ways.

1. Processing from low-octane benzine to high-octane.

2. Mixing in necessary proportions of once-run benzine with high-octane, not ethylated

additives (WATERS and etc) This way allows to raise octane value of once-run benzine to 10-15

units.

From the existing processes the most efficient is the process of once-run benzine in highoctane method "ZEOFORMING", developed by Scientific Researching Centre "ZEOSIT" by

Russian Academy Of Sciences (Novosibirsk city). It is allows to produce benzines from AI-80 up to

AI-95, and also European such as "EUROSUPER-95" without addings and compoundition. As

against traditional processes of top bracket gasolines reception - reforming - process ZEOFORMING

does not demand application of hydrogen, hydroclearing of raw material, expensive platinum

catalysts.

4

The basis of technology consists of catalytic conversion of low-octan liquid hydrocarbons in

high-octane components of benzines on zeolite-content catalysts such as IK-30-1.

According to the licenses and baseline designs Scientific Researching Centre "ZEOSIT"

plants "ZEOFORMING" with capacity from 5 up to 40 thousand tons a year are constructed: Russia

(Nizhnevartovsk Gas Plant, 1992 - 5 thousand ton/year), Poland (Oil Plant "GLIMAR", 1997 - 40

thousand ton/year about the design of firm " Lurgi "), Kirghizia (Bishkek, 1998 - 40 thousand

ton/year), Georgia (Rustavi, 2002 - 40 thousand ton/year), South Korea ( DAYJOHN, 2001,

demonstration unit, together with company "Samsung"). Industrial production of catalysts is created

on «Novosibirsk factory chimkonzentratov».

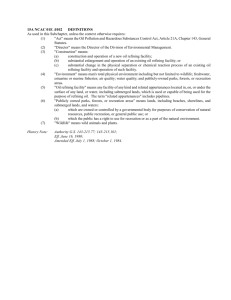

The diagram of oil refining on "THERMOKAT" technology is submitted on

pic. 1.

5

Pic. 1 Basic circuit of oil refining

desalinized oil, dry oil,

100 %

Atmospheric

distillation

Gas, 1 %

Benzine fraction -180С,

10 %

Diesel fraction.

180-360С, 33,0%

Black oil, 56%

Process

Secondary gas, 2%

Secondary benzine,

180, 9%

viscosity breaking -

«THERMOKAT»

Secondary diesel

fraction, 32%

Bitumen, 13%

Hydrocarbon gas, 3%

Benzine (180С), 19 %

Bitumen, 13 %

Process

ZEOFORMING

Liquefied gas

High-octane benzine, 65-85%

6

Diesel fuel

(180-340С), 65%

3. Configuration of the unit and placement.

Refinery settles down in the place with necessary engineer infrastructure, including

tank battery, security systems, household rooms. The process equipment can be executed

from separate technological blocks of factory manufacture in forms of modules which

are convenient for transportation. The modules are placed in an open area with a canopy

and easy protect designs.

The rough area occupied with technological blocks for the unit with productivity of

100 thousand ton/year makes ~ 20х60 m. The sizes of a platform for an oil refining

complex as a whole with infrastructure depend on rhythm of supply raw material and

shipment of production (volume of tank battery), presence and such as the access roads,

approved schema of automation, power supply, conditions of life for the personnel, etc.

All these parameters are defined at the project stage on the starting data of the

Customer and the chosen platform.

4. Automation, power supply, the analytical control.

In the project of the unit automation the following is stipulated:

- Measurement, the remote control and registration of technological process

parameters;

- Automatic control of technological parameters;

- The preventive signal system of dangerous parameters;

- Automatic protection of pumps and devices by achieving the process of

permissible values for this equipment of the parameters ;

For control and process monitoring are chosen the modern electronic gauges

working with transducers and receiver recorders. In the system are applied only singlepoint devices.

The regulating accessory is used with air-operate transforming the electric signal in

pneumonic with the help of electrical air-operated transducers of hardened execution.

All means of the control and automatics of a domestic production have certificates

of conformity and the sanction to application in explosive installations.

Management of the unit is conducted from operational office, located outside of an

explosive zone with two tambour entrances. In the operational office constant ventilate

air with air-condition is created.

In basic technology three-phase electric power is consumed. It can be taken over

from existing systems of electro delivery. For heating raw material fuel developed on the

unit is used. For start-up of the unit you need starting volume of fuel for start and work

within 2 days, heating and reactionary technological furnaces. The necessary stock of

liquid fuel makes ~ 10 m3.

Refinery is provided with emergency system of power supply - diesel generator as

the oil refining enterprises should have two independent sources of power supply.

The analytical control of the process is carried out by standard methods of analyses

in accordance with GOST, on the routine lab ware with routine methods of selection of

mineral oil and designs of samplers. At the self-contain schema of the unit the laboratory

is equipped in mobile wagon.

7

5. Ecological aspects of unit operation.

At the full-time work of the enterprise flue gases of technological furnaces P-1,2

and the furnaces of heat-transfer medium P-3 are sources of pollution liable to clearing.

These gases are formed at the combustion of fuel and they contain dioxide of sulfur in

concentration up to 0,05 % of weights, nitric oxides in concentration up to 0,00005 % of

weights.

The project of the unit does not suppose using water for cooling production lines.

There are cooling devices purpose use in this unit.

At any contingencies temporary passages of mineral oil are possible while

performing technological operations or repair equipment. In this case procast mineral oil

is covered by sorbent. The fulfill sorbent goes to a metal pressure-tight container and

puncheons and is manufactured further together with Mechanic admixings, collected

from filters of pumps. A surface is washed out by industrial water, containing

PEAHENS, the outwashes go to the system of industrial sanitary piping.

The Solid waste products from Zeoforming unit are fulfilled zeolite - catalyst IK30-1.

Before the unloading, the catalyst is subjected to annealing at temperature 450 С

by feeding reclaiming gas that provides complete removal from the catalyst of

hydrocarbons and the coke deposited on the catalyst.

The fulfilled and cleared catalyst has no toxicological properties and goes to the

dump. The work is underway on possible usage of dead-catalyst in road building as filler

for concrete coverings which don’t stand heavy traffic (concrete paths, platforms, etc.)

Operating the enterprise the periodic control of the contents of harmful substances,

starting, intermediate and termination products in air of the industrial rooms, the occupied

places, in water of reservoirs and ground by meothods of the tool control over techniques,

fixed Federal Hydrometereology and Environmental Monitoring Service is manufactured.

The platform for placement Oil Refiner should be on distance not less than 1000 m

from habitable area. Other requirements are defined at the project stage and are similar to

the requirements showed to warehouses of the PETROL PRODUCTS.

8

6. Basic characteristics of the Refiner and products of raw

material processing.

Oil refining in blocks of atmospheric distillation and "THERMOKAT" it is

possible to receive the following products .

The basic nomenclature:

- component of benzine A-76 according to GOST 2084-77 (on fractional

composition);

- component of summer, winter and Arctic solar oil according to GOST

305-82 (on fractional composition);

Or

- furnace household fuel according to technical specifications 38.101656-87;

- fuel oil according to GOST 10585-75;

Or

- bitumens road not oxidated according to technical specifications 025609600151807-97.

- To bring obtained products of oil refining up to a commodity output it is

necessary to apply corresponding additives and reagents including:

The name of

Materials

The charge, kg /

Comment

tons of Commodity

output

Soda caustic liquid (caustic soda), 38

3,1

Alkalining benzine

% water solution

Methyltrebutyl ether,

37,5*

Component of benzine

Or its analogue

Agidol

0,7

Antioxidizing dopant to engine

fuels

Lime calcium unslake

10

Component of a mineral filler

asphaltconcrete

Iron (III) sulphate

0,08

Component of absorbent of

hydrogen sulphide

Trilon-B

0,1

Component of absorbent of

hydrogen sulphide

Nitrogen technical

0,04

Noble gas for blow-down of

the equipment

9

* Depending on type of raw material.

As a result of such compounding it is possible to receive the following basic

nomenclature:

- Benzines A-76 - A-93 in accordance with GOST 2084-77;

- Solar oil with improved ecological properties (summer, winter) under

technical specifications 38.401-58-170-96.

Reception of high-octane commodity benzines only by compounding is rather

problematic and, as a rule, can be provided by processing very "good" petrol. Traditional

compositions do not allow to increase octane value by introduction of dopants more than

76.

There are opportunities for padding nomenclature of production obtained by

updating of regime parameters: nefracs on OST 3801199-80, mobile ship fuel on

technical specifications 38.101567-87, black oil naval in accordance with GOST

10585-75, residual fuel SVT, SVL, CDC on technical specifications 38.1011314-90,

bitumens structural{building} in accordance with GOST 6617-76, bitumens

insulation in accordance with GOST 9812-74; bitumens roofing in accordance with

GOST 9548-74; bitumens friable in accordance with GOST 21822-87.

For production of commodity output on blocks AT and "THERMOKAT"

following rough resources are required:

The charge on 1 ton raw material

The name

1. Solar oil, or fuel gas (at the moment of start-

33

up), kg

2. Air KIA, nm3

2,6

3. Nitrogen, periodically, nm3

At start-up and stop

4. The electric power, kw. / hour

15

By production of top bracket benzines on "ZEOFORMING" block the following

rough charges of by-products are required:

The charge on 1 ton raw material

The name

1. Catalyst, kg

0,1/0,2 *

2. Solar oil, or fuel gas (at the moment of start-

37,4

up), kg

3. Air KIA, nm3

19,2

4. Nitrogen, periodically, nm3

3,9 / 8,6 *

5. The electric power, kw / hour

37,2

*By production of benzines AI-76 and AI-95 accordingly.

10

7. Economic indexes of small capacity refinery.

Quantitative value of fuel production, developed on unit, is defined, basically, by

the composition of the feed stock (oil), and also the chosen type of end product.

For one of the Tyumen origin Oils the following ratio between termination products

are obtained:

Oil crude

- 100 %

Benzine AI-92

- 25 %

Solar oil (summer)

- 58 %

Bitumen not oxidated

- 12 %

Losses, expenses on

preheating of raw material and work of aggregates

-5%

For installation with productivity of 100 thousand ton/year on raw material the

commodity output will make :

Benzine AI-92

- 25 thousand тons/year

Diesel Fuel

- 58 thousand тons/year

Bitumen not oxidated - 12 thousand тons/year

The total cost of the unit (without "Zeoforming" block) with a building part and

infrastructure will make ~ 10 million euro, including the process equipment - 6 million

euro . The specified cost will be specified at the stage of concrete Refenery design with

its concrete location and raw material.

11

8. Financial plan

Economic efficiency of realization of any investment project directly depends on

existing economic conditions for the business, the existing price level and tax policy that

works in the market of Altai krai.

Volume of necessary investments:

1. Investments (cost of the unit and infrastructure) 8.500.000 EUR or

293,250,000.00 roubles (the Central Bank of the Russian Federation

rate on 01.04.2007 34.50 roubles / EUR), including VAT of 18 %;

2. Necessary initial turnaround means for maintenance of 30-days

need of raw material of 51.750.000 roubles, including VAT of 18 %

(or 1.500.000 EUR);

Total: 345,000,000.00 roubles, including VAT of 18 %.

(or 10.000.000 EUR)

Calculation is made in real terms (as of 01.04.2007) and taking into account the

following accepted essential starting parameters:

1. Internal parameters

1.1. The charge of raw material on total output of 100 thousand tons of oil in one year

1.2. The production program of output is determined by technological process and

assumes the following ratio of a feed stock and termination products of processing:

- Oil crude

- 100 %

- Benzine A-80

- 25 %,

-Solar oil (summer)

- 58 %,

-Bitumen

- 12 %,

-Losses, expenses of production on

Preheating of raw material - 5 %.

1.3. The given variant of calculation gives full realization of the manufactured products,

thus sales volume is defined by level of industrial loading and on total output makes 47,5

thousand tons of mineral oil a year.

plan of sales

Quarter plan

In tons

1. Benzine A-80

Year plan

In tons

Quarter plan

In roubles

Year plan

In roubles

6 250

25 000

105 386 808

421 547 232

2. Diesel oil

14 500

58 000

265 891 886

1 063 567 540

3. Bitumen

3 000

12 000

19 918 234

12

Total

23 750

95 000

391 196 928

79 672 936

1 564 787 710

2. External parameters

2.1. A wholesale price for oil and mineral oil from the factory on the

average on Ural-Siberian Region (the Internet source www.riccom.ru):

- Oil crude

- Benzine A-80

- Solar oil (summer)

- Bitumen

- 7000 roubles/ton

- 16000 roubles/ton,

- 17400 roubles/ton,

- 6300 roubles/ton

2.2. Expenses for processing of 1 ton of oil at total output make 1300 roubles and

include the salary of the personnel with deductions, expenses for certification,

municipal services, the electric power and other working costs

2.3. Norms of deductions and the rates of taxes established by the Government of Russia

2.3.1. The norm of depreciation charges on oil refining installations according to

Classification of the basic means, authorized by the Government of Russian

Federation from 01.01.02, makes 9 % (group 6, from above 10 and till 15 years

inclusive)

2.3.2. Value Additional Tax (VAT) of-18 %

2.3.3. Property Tax

- 2,2 %

2.3.4. Profits Tax

- 24 %.

2.3.4. Excises: A-80 - 2700 roubles / ton; Solar oil - 1080 roubles / ton.

In total:

Expenses for processing – 130 000 000 roubles.

Excises A-80

- 67 000 000 roubles.

Diesel fuel

- 62 640 000 roubles.

Taxes

- 166 000 000 roubles.

In total payments

- 462 140 000 roubles.

Raw material

- 751 712 362 roubles.

As a result we have for 1 year:

1 564 787 710 roubles of receipt from sale

-1 213 852 362 roubles - expenses

________________________

350 935 348 roubles or 10 172 039 EUR .

It is necessary to notice, that reduction of the price on 3 %, plus reduction

of charges on delivery, plus an opportunity of buying by gasoline tank trucks, make

our production quite competitive. All given calculations are given with stress on

Tyumen oil, we shall present the standard data in the elementary diagram of

processing.

The high performance schema of raw material processing provides either high

profitability of production or fast term of recovery of outlay investments. For the unit

with productivity of 100 thousand tons/year on raw material the term of outlay recovery

takes 1 year.

The term of the Refinery building takes 8-10 months.

13

Such factories are supposed to be replaced in Altai krai, as a minimum ten of them with

volume of 1000000 tons one year that makes 45 % from all consumer market of mineral

oil in the region. The sum of expenses accordingly will increase up 100.000.000 EUR.

14