P35785 - BrainMass

advertisement

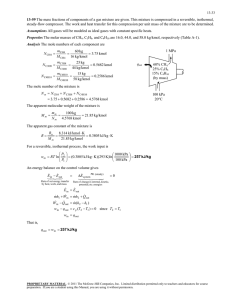

Problems 1. Gaseous Propane at 25ºC is burned with moist air at 400 K in a steady state, steady flow process. The combustion process is adiabatic, and the exiting temperature is measured to 1200 K. A sample of the products is tested and found to have a dewpoint temperature of 70ºC. Determine the percentage of theoretical air used and the relative humidity of this air. Assume the combustion is complete and that the pressure is 100 KPa throughout the process. 2. A mixture of 80% ethane and 20% methane on a mole basis is throttled from10MPa, 65ºC, to 100 KPa and is fed to a combustion chamber where it undergoes complete combustion with air, which enters at 100 KPa , 600 K. The amount of air is such that the products of combustion exit at 100 KPa , 1200 K. Assuming that the combustion process is adiabatic and that all components behave as ideal gases except the fuel mixture, which behaves according to the generalized tables or charts, with pseudocritical constants, determine : a) the percentage of theoretical air used in the process b) the dew-point temperature of the products Solution: 1) Notations: Nx = number of kmols of component (x) Mx = molar mass of component (x) (kg/kmol) rx = the molar (volumetric) percentage of component “x” in a mixture Q = molar heat exchange (kJ/kmol) = universal constant of gases, = 8.314 kJ/kmol.K Cp = molar specific heat at constant pressure (kJ/kmol.K) cp = mass specific heat at constant pressure (kJ/kg.K) = air excess coefficient = volumetric ratio nitrogen/oxygen of air composition, = 3.762 d = moisture content in the air, d = kg vapors / kg dry air = relative humidity of air (mixture) The stoichiometric oxidation reaction of propane with dry air is: C3H8 5O2 N2 3CO2 4H2O 5N2 ( 1) while the actual reaction with dry air in excess is C3H8 5O2 N2 3CO2 4H2O 5 1O2 5N2 ( 2) Now, we consider a humid air coming into reaction. If (d) is the moisture content, we can compute the molar fraction of water content in the air: M N M Nw M 29 d w w w d a d 1.61d Ma N aM a Na Mw 18 Thus, for every kmole of dry air, we have 1.61d kmoles of water (gaseous). Therefore, our equation becomes: C3H8 5O2 N2 8.051 dH2O 3CO2 4 8.051 dH2O 5 1O2 5N2 ( 3) where 8.05 = 5 x 1.61 We have 2 parameters which need to be determined: () = excess of air d = the degree of moisture The conditions which allow to compute these parameters are: the dew point of products the temperature of products If we know the dew point of products, we can find out by means of Steam Tables the partial pressure of water vapors in the exhaust mixture. Thus, at a saturation temperature of 70 deg. Celsius, we find that the corresponding saturation pressure is ps = 0.312 bar ( 4) According to Dalton’s law, we have pi Ni p N ( 5) for every component (i) in a mixture. Since the exhaust gases pressure is 100 kPa = 1 bar, that means N H 2O 0.312 N ( 6) where (N) = total number of kmoles of exhaust products: N 3 4 8.051 d 5 1 5 2 8.051 d 51 ( 7) But N H 2O 4 8.051 d ( 8) so that 4 8.051 d 0.3122 8.051 d 51 ( 9) 4 8.051 3.762d 0.624 2.511 3.762d 1.561 3.762 4 38.33d 0.624 11.95d 7.43 26.38d 7.43 3.376 d 0.282 0.128 Now, we need to apply the energy equation which allows to determine the exhaust temperature (that we know) Since the burning process takes place at constant pressure, we can write: ( 10) Qreaction N i Cp i Tf N i Cp i Ti i reac tan ts i products ( 11) where (Qreaction) will be expressed in kJ/kmole fuel, since we have 1 kmole propane in equation, and Tf = final temperature. From databases, we find the following: H2Ovap cp = 2.84 kJ/kg.K Cp 2.84 18 51.12 kJ/kmol.K CO2 cp = 1.37 kJ/kg.K Cp 1.37 44 60.28 kJ/kmol.K N2 cp = 1.28 kJ/kg.K Cp 1.28 28 35.84 kJ/kmol.K O2 cp = 0.906 kJ/kg.K Cp 0.906 32 29 kJ/kmol.K Air cp = 1.005 kJ/kg.K Cp 1.005 29 29.15 kJ/kmol.K C3H8 cp = 1.68 kJ/kg.K Cp 1.68 44 73.92 kJ/kmol.K Qreaction = 2210000 kJ/kmolfuel By replacing in (1), we get Qreaction N i Cp i Ti i reac tan ts Tf N i Cp i i products 73.92 25 273) 5 (1 3.762) 29.15 400 8.05d (1 3.762) 51.12 400 2210000 Tf 3 60.28 4 8.05 1 3.762d 51.12 5 1 29 5 3.762 35.84 22028.16 277624.6 783855.7d 2210000 1200 240.32 819.15 1959.6d ( 12) 22028.16 277624.6 783855.7d 2210000 288384 98298 2351520d 1567664.3d 1943644.16 179326.6 ( 13) By replacing (d) with (10), one yields 0.128 1567664.3 0.282 1943644.16 179326.6 442081.3 200661 1943644.16 179326.6 262754.7 2144305.16 d 0.282 8.161 0.128 0.266 8.161 ( 14) ( 15) The formula which relates the relative humidity () to the moisture content (d) is: d 0,622 ps p ps ( 16) where ps = saturation pressure at given temperature (in our case is 0.312 bar) p = actual pressure of the humid air (or mixture) d ( p ps ) 0.622 ps d p d 0.622 ps ( 17) 0.266 1 0.96 96% 0.266 0.622 0.312 2) a) Throttling real gases is a complex process, which requires additional information, like what type of transformation the gas is submitted to. It could be adiabatic, isenthalpic or isentropic, depending of the throttle. For us, it is important to know the temperature after throttling, in order to compute the enthalpy addiction in the burning process. However, since the temperature after throttle is much less than 65 deg Celsius, we will simplify the calculations and will neglect the enthalpy of the fuel mixture. We will consider only the enthalpy of the air and the combustion heat which, together, will determine the exhaust temperature. The error will be less than 2%. Since the molar ratio ethane/methane is 80% / 20% = 4 : 1, the chemical reaction (stoichiometric) will be described by the equation 4C2H6 CH4 16O2 N2 9CO2 14H2O 16N2 ( 18) If we have an air excess defined by factor (), then he above equation becomes 4C2H6 CH4 16O2 N2 9CO2 14H2O 16 1O2 16N2 ( 19) The energy equation which allows to determine the exhaust temperature (that we know) is the following, since the burning process takes place at constant pressure: i N i Qreact N i Cp i Tf N i Cp i Ti i i reac tan ts i products ( 20) where (Qireact) is the molar heat of reaction for the fuel “i”, which is expressed in kJ/kmole fuel and Tf = final temperature. By developing the above equation according to (19) and neglecting the enthalpy of fuel, we can write: 16 Cp O 2 Cp N 2 Tair 4Q C 2H 6 Q CH 4 9Cp CO 2 14Cp H 2O 16 1Cp O 2 16Cp N 2 Tf We need to solve this equation in (): ( 21) 16 Cp O 2 Cp N 2 Tf Tair 4Q C 2H 6 Q CH 4 9Cp CO 2 14Cp H 2O 16Cp O 2 Tf ( 22) 4Q C 2H 6 Q CH 4 9Cp CO 2 14Cp H 2O 16Cp O 2 Tf 16 Cp O 2 Cp N 2 Tf Tair ( 23) From Thermodynamic databases, we find: (Q)C2H6 = 1560000 kJ/kmol (Q)CH4 = 890000 kJ/kmol H2Ovap cp = 2.84 kJ/kg.K Cp 2.84 18 51.12 kJ/kmol.K CO2 cp = 1.37 kJ/kg.K Cp 1.37 44 60.28 kJ/kmol.K N2 cp = 1.28 kJ/kg.K Cp 1.28 28 35.84 kJ/kmol.K O2 cp = 0.906 kJ/kg.K Cp 0.906 32 29 kJ/kmol.K By replacing these values in (23), we get 4 1560000 890000 9 60.28 14 51.12 16 29 1200 3.927 16 29 3.762 35.84 1200 600 Remark: In general, when burning fuels with excess of air, one neglect the enthalpy of the fuels at inlet, since this is much less than the other relevant amounts of energy involved in the energetic balance. For example, I was dealing with burning process in the combustion chambers of jet engines which use kerosene as fuel ( a mixture of liquid hydrocarbons) and I never considered the enthalpy of the fuel at inlet. The results that I’ve got were in good accordance with experimental data. b) In order to find the dew point of exhaust products, we need to know the molar fraction of water vapors in the exhaust mixture, which allow to compute the partial pressure of them. According to (19), we have rH 2O N H 2O 14 N 9 14 16 1 16 ( 24) By replacing with numercal values, we get rH 2O 14 0.0457 9 14 16 3.927 1 16 3.762 3.927 ( 25) Therefore, according to Dalton’s law, the partial pressure of water vapors in the exhaust mixture will be: pg 100 kPa 1 bar pH 2O 0.0457 bar Considering this as a saturation pressure, from Steam Tables we can find the corresponding saturation temperature: TS = 304.4 K = 31.4C This is the dew point of exhaust mixture that we were looking for.