General Overview of HAZOP Method - Hrdp

advertisement

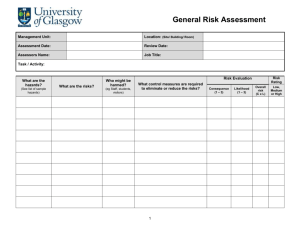

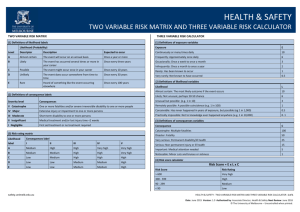

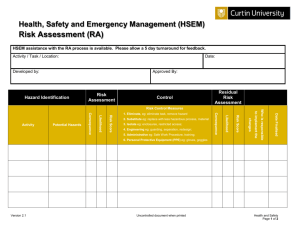

General Overview of HAZOP Method Compiled by: Dr. Asit K Patra, Asstt. Director, DMI, Bhopal 1.1 Background – Concept of HAZOP A HAZOP (HAZard and OPerability) study identifies hazards and operability problems in a process plant. It is a tool for the identification of hazards due to process parameter deviations. The concept involves investigating how the plant might deviate from the design intent. HAZOP is based on the principle that several experts with different backgrounds can interact and identify more problems when working together than when working separately and combining their results. Although the HAZOP study was developed to supplement experience-based practices when a new design or technology is involved, its use has expanded to almost all phases of a plant's life. The “Guide-Word” HAZOP is the most well known of the HAZOPs; however, several specializations of this basic method have been developed. The HAZOP concept is to review the plant in a series of meetings, during which a multidisciplinary team methodically “brainstorms” the plant design, following the structure provided by the guide words and the team leader's experience. The primary advantage of this brainstorming is that it stimulates creativity and generates ideas. This creativity results from the interaction of the team and their diverse backgrounds. Consequently the process requires that all team members participate (quantity breeds quality in this case), and team members must refrain from criticizing each other to the point that members hesitate to suggest ideas. The team focuses on specific points of the design (called "study nodes"), one at a time. At each of these study nodes, deviations in the process parameters are examined using the guide words. The guide words are used to ensure that the design is explored in every conceivable way. Thus the team must identify a fairly large number of 1 deviations, each of which must then be considered so that their potential causes and consequences can be identified. The success or failure of a HAZOP study depends on several factors, to name a few: The completeness and accuracy of drawings and other data used as a basis for the study The technical skills and insights of the team The ability of the team to use the approach as an aid to their imagination in visualizing deviations, causes, and consequences The ability of the team to concentrate on the more serious hazards which are identified. In the process of identifying problems during a HAZOP study, if a solution becomes apparent, it is recorded as part of the HAZOP result; however, care was taken to avoid trying to find solutions which are not so apparent, because the prime objective for the HAZOP is problem identification. 1.2 Various Terms used in HAZOP Study The HAZOP process is systematic and it is helpful to define the terms that are used in the study: A. Study Nodes - The locations (on piping and instrumentation drawings and procedures) at which the process parameters are investigated for deviations. B. Intention - The intention defines how the plant is expected to operate in the absence of deviations at the study nodes. This can take a number of forms and can either be descriptive or diagrammatic; e.g., flow-heets, line diagrams, P&IDs. C. Deviations - These are departures from the intention which are discovered by systematically applying the guide words (e.g., "more pressure"). D. Causes - These are the reasons why deviations might occur. Once a deviation has been shown to have a credible cause, it can be 2 treated as a meaningful deviation. These causes can be hardware failures, human errors, an unanticipated process state (e.g., change of composition), external disruptions (e.g., loss of power), etc. E. Consequences - These are the results of the deviations should they occur (e.g., release of toxic materials). Trivial consequences, relative to the study objective, are dropped. F. Guide Words - These are simple words which are used to qualify or quantify the intention in order to guide and stimulate the brainstorming process and so discover deviations. The guide words shown in Table 1 are the ones most often used in a HAZOP; some organizations have made this list specific to their operations, to guide the team more quickly to the areas where they have previously found problems. Each guide word is applied to the process variables at the point in the plant (study node) which is being examined. These guide words are applicable to both the more general parameters (e.g., react, transfer) and the more specific parameters (e.g., pressure, temperature). Table 1: HAZOP Guide Words and Meanings Guide Words Meaning No Negation of the Design Intent Less Quantitative Decrease More Quantitative Increase Part Of Qualitative Decrease As Well As Qualitative Increase Reverse Logical Opposite of the Intent Other Than Complete Substitution 3 With the general parameters, meaningful deviations are usually generated for each guide word. Moreover, it is not unusual to have more than one deviation from the application of one guide word. For example, "more reaction" could mean either than a reaction takes place at a faster rate, or that a greater quantity of product results. With the specific parameters, some modification of the guide words may be necessary. In addition, it is not unusual to find that some potential deviations are eliminated by physical limitation. For example, if the design intention of a pressure or temperature is being considered, the guide words "more" or "less" may be the only possibilities. Finally, when dealing with a design intention involving a complex set of interrelated plant parameters (e.g., temperatures, reaction rates, composition, or pressure), it may be better to apply the whole sequence of guide words to each parameter individually than to apply each guide word across all of the parameters as a group. Also, when applying the guide words to a sentence it may be more useful to apply the sequence of guide words to each word or phrase separately, starting with the key part which describes the activity (usually the verbs or adverbs). These parts of the sentence usually are related to some impact on the process parameters. 1.3 HAZOP Methodology The concepts presented above are put into practice in the following steps: 1. 2. 3. 4. 5. Define the purpose, objectives, and scope of the study Select the team Prepare for the study Carry out the team review Record the results. It is important to recognize that some of these steps can take place at the same time. For example, the team reviews the design, records the findings, and follows up on the findings continuously. 4 1.4 Risk and Risk Matrix in HAZOP study In the context of process safety management, Risk is defined in terms of the likelihood and consequences of incidents that could expose plant personnel, property, assets, process and environment to the harmful effects of a hazard. According to Centre for Chemical Process Safety of the American Institute of Chemical Engineers, hazards are potential sources of harm, including chemical or physical conditions or characteristics that can damage people, property or the environment. Incident likelihood encompasses frequency and probability; consequences refer to outcomes and impacts. Risk ranking uses a matrix that has ranges of consequence and likelihood as the axes. A typical risk matrix is a 4 x 4 grid. 5 1.5 Design of Risk Matrix in HAZOP study Although there are many risk matrices that have been developed, effective risk ranking tools in day-to-day operations, such as during hazard and operability (HAZOP) studies are very limited. Layer of Protection Analysis (LOPA) approach is one of them. It is simple to implement and easy for most HAZOP participants to understand. 1.5.1 Various Layers of Protection in a Process Plant HAZOP study deals with the identification of hazards due to process parameter deviations. When a failure occurs due to deviations, it may take the process outside of its normal operating ranges. In general, there are several layers of protection measures in a plant in response to a process deviation. The basic process controls, alarms, safety valves, operator supervision etc. are the typical protection measures against any harmful consequences due to deviation of process parameters as shown below: Process equipments are designed for process operating limits. Basic process controls, alarms and operators are adjusted to process deviations. Presence of Critical Alarms along with Speedy Response of Operators. Safety Interlock System/Emergency Shut Down at operating limits. Relief Systems that activate at equipment design limits. Mitigation systems that contain the effects of incident. Plant emergency response to control the effects of incidents (On-site Control Arrangement). Emergency response to protect the public from the effects of an incident (Offsite Control Arrangement). 6 1.5.2 Likelihood and Consequences Ranges In LOPA approach, the highest likelihood range (Level 4) is defined by the likelihood of the initiating event, e.g. human error, control failure etc. Then for each level of existing protection measure, likelihood range is reduced by one level. This approach assumes that each level of protection has a similar failure probability, which is generally acceptable for rough risk screening such as HAZOP risk ranking. Some failures have fairly well defined frequencies of occurrences and can be directly used. For example, catastrophic failure of a pressure vessel has a frequency in the range of 10-5 per year and thus by itself would be considered as Level 1 likelihood. Similar likelihood levels can be defined for other common equipment failures, pipe leaks, ruptures etc. (Refer to: CCPS Guidelines for Process Equipment Reliability Data, AIChE, 1999). The above likelihood ranges can be used in conjunction with typical consequence ranges to people, property and environment. The following Table 2 and 3 show the likelihood ranges and consequence ranges respectively. In the likelihood range, highest chances of occurrences have been given to leaking scenarios etc., associated with least protection measures in a plant. Similarly, catastrophic failure of tanks/process vessels has the least chances of occurrence and also associated with various protection measures against failures. In the consequence ranges, major aspects, viz., human injury/fatality, environmental impact, production loss, product quality etc. have been considered. Table 2: Likelihood ranges based on levels of protection Likelihood Range 1 2 3 4 Qualitative Frequency Criteria: Typical Scenarios * Three levels of protection * Tank/process vessel failures * Two levels of protection * Full-bore failures of small process lines or fittings *One level of protection * Piping leaks *Initiating event/Human Error *Hose leaks/rupture 7 Table 3: Typical Consequence ranges Consequence Range 1 Qualitative Safety Consequence Criteria 2 3 4 Injuries requiring first-aid only. Product quality affected and damage value range: Rs. 10,000 – 1 lakh. Contained release with local environmental impact and Pollution problem. Injuries requiring a physician’s care. Damage value Range: Rs. 1 lakh – 10 lakh. Uncontained release with potential for minor environmental impact. Chances of fire and explosion. Severe Injuries or Potential for a fatality Damage value range: Rs. 10 lakh - 1 Crore. Uncontained release with potential for moderate environmental impact. Multiple life threatening injuries and/or fatality Damage value range: More than Rs. 1 Crore. Uncontained release with potential for major environmental impact. 8 1.5.3 Risk Ranking Matrix and Acceptability Values Based on the likelihood and consequence ranges, risk ranking has been defined with suitable acceptability criteria as shown in Table 4. Table 4: Risk Rank Value and Acceptability Criteria Risk Rank Value Explanation 1–2 Acceptable as it is 3–4 Acceptable with Controls 5–9 Undesirable; Mitigation Required to Reduce Risk >9 Unacceptable ******* 9