SYNTHESIS AND APPLICATIONS OF SUPERHYDROPHOBIC

advertisement

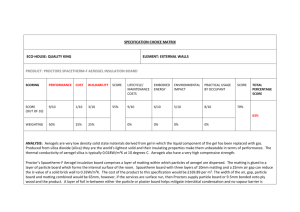

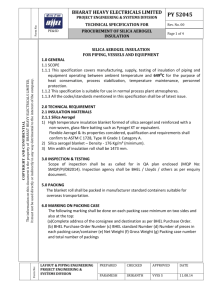

SYNTHESIS AND APPLICATIONS OF SUPERHYDROPHOBIC SILICA AEROGELS Venkateswara Rao Air Glass Laboratory, Department of Physics, Shivaji University, Kolhapur, Maharashtra, India Abstract. Synthesis of non-wetting (hydrophobic) solid surfaces is an active area of research in recent years because it forms the basis for multidisciplinary applications such as frictionless flow of liquids through nano- and micro-channels and pipes, waterproof and corrosion resistance coatings and drug delivery systems. In this lecture, the experimental results on the synthesis, physico-chemical properties and applications of superhydrophobic silica aerogels, are presented. The aerogels have been produced using methyltrimethoxysilane (MTMS) precursor by two step sol-gel process. The contact angle has been found to be as high as 175°. The elastic properties of these aerogels have been studied and the Young's modulus (Y) has been found to decrease from 14.11 x 104 to 3.43 x 104 N/m2 with a decrease in the density of the aerogels from 100 to 40 kg/m3, respectively. The aerogels are thermally stable up to a temperature of 753 K and above which they become hydrophilic. The criticality of the water droplet size on the superhydrophobic surface has been found to be 2.7 mm. The velocity of the water droplet on such a superhydrophobic surface has been observed to be 1.44 m/s for 55° inclination, which is close to the free fall velocity (~1.5 m/s). Further, the as produced aerogels have been used for organic liquid (i.e. alkanes, aromatic compounds, alcohols and oils) absorption and desorption studies. The superhydrophobic aerogels showed a very high uptake capacity and high rate of uptake of the organic liquids. Among the alkanes, the mass of octane absorbed was a maximum of 15.62 gm per unit mass (1 gm) of the aerogel samples. While, among the alcohols, the mass of butanol absorbed was maximum (~19 gm). The desorption of solvents and oils was studied by maintaining the as absorbed aerogel samples at various temperatures. The vapour pressure is very high (732.7 mm of Hg at 30oC) for pentane which led to faster evaporation. Hence the rate of desorption of pentane is more. In the case of alkanes, after the desorption, the aerogels regained their original shape and size. The best quality elastic superhydrophobic aerogels in terms of contact angle (175o), density (37 kg/m3), shrinkage (6%), porosity (98%) and thermal conductivity (0.057 W/mK) have been obtained for the molar ratio of MTMS: MeOH: acidic water: basic water:: 1: 35: 3.97 : 3.97, respectively. The hydrophobicity has been confirmed by Fourier Transform Infrared (FTIR) spectroscopy and the contact angle measurements. The microstructure of the aerogels has been studied by transmission electron microscopy (TEM). The Young's modulus of the aerogels has been determined by an uniaxial compression test measurements. 1. INTRODUCTION Silica aerogels are sol-gel-derived materials consisting of interconnected nano particle building blocks, which form an open and highly porous three-dimensional silica network. Typical silica aerogels have high surface area (~ 1000 m2/g), high optical transmission (~ 93%), low density (40 kg/m3) and low thermal conductivity 5-2 (0.02 W/mK) [1-4]. These features have led the aerogels to various applications in science and industry such as Cerenkov radiation detectors [5], inertial confinement fusion (ICF) targets [6], lightweight thermal and acoustic insulation [7], catalytic supports [8], microfilters [9], supercapacitors for electric cars [10] and controlled release of drugs [11]. Despite of all these fascinating properties, the aerogels have major drawbacks that they are fragile, brittle and moisture sensitive, which limit their applications in various fields. Furthermore, considering the adverse impact to ecosystems and the environmental pollution by the accidental and deliberate release of oil and other organic liquids during transportation and storage, experiments were conducted to synthesize flexible and superhydrophobic silica aerogels using methyltrimethoxysilane (MTMS) as a precursor and to test their usability as efficient and effective absorbent of oil and other organic liquids. The as produced silica aerogels were found to be highly flexible and superhydrophobic with excellent absorption properties of oils and other organic liquids. The aerogels showed a very high uptake capacity, high rate of uptake and above all. They could be recycled to get back the organic liquids and the aerogels could be reused as absorbents. It was observed that aerogels absorbed the organic liquids by more than 20 times and oils by nearly 14 times of their own mass. 2. Experimental Procedures 2.1 Sample preparation The synthesis of the superhydrophobic silica aerogels involves two major steps: (1) the preparation of alcogels by a two step acid-base catalyzed sol gel process and, (2) the supercritical drying of the wet gels to remove the solvent. The chemical reactions responsible for the formation of three dimensional gel network structure, are as follows. Hydrolysis: OCH3 H3C OH C2H2O4 OCH3 + 3H2O Si MeOH H3C OCH3 Si OH + 3CH3OH OH MTMS Silanol Condensation: OH OH 2 H3C OH NH4OH H3C Si OH OH + HO Si O H3C Si Si O Si OH OH Si – O – Si Network 5-3 CH3 + 4 H2O O O CH3 OH Si OH CH3 Initially, methyltrimethoxysilane (MTMS) was diluted in methanol (MeOH) solvent and was partially hydrolyzed with water under acidic conditions with oxalic acid (0.001M). In the second step, after one day, the condensation of these hydrolyzed species was carried out in the presence of a base catalyst, NH4OH (10M), to get the alcogels. The alcogels were aged for two days in methanol and then they were supercritically dried in an autoclave at a temperature of 2650C and a pressure of 10 MPa to obtain the aerogels (Figure 1). Solvent molecules Silica particles Sol Gel Aerogel Fig. 1. Schematic diagram of the sol-gel process. 2.2. Methods of characterization The as prepared aerogels were characterized by the bulk density, porosity, volume shrinkage, thermal conductivity and contact angle measurements. The microstructure of the aerogels was studied using Transmission Electron Microscope. The Young's modulus (Y) of the aerogels was determined by an uniaxial compression test as shown in the Figure 2. In this test, various loads (e.g. 0.01 kg, 0.02 kg, 0.03 kg etc.) were applied on the cylindrical aerogel sample and the corresponding change in length (∆ L) was measured using a travelling microscope. Finally, the Young's modulus of the aerogel samples was calculated by using the formula: Young's modulus (Y) = mgL / r2(∆ L) = (Lg/r2) / slope (1) where, L is the original length of the aerogel before deformation and r is the radius of the aerogel. The absorption and desorption studies of the as prepared superhydrophobic aerogel sample was done by putting it in an organic solvent until it was completely wetted by the liquid. Then it was removed and maintained at various temperatures in an oven The rate of desorption was studied by weighing the aerogel sample in a micro balance before absorption, immediately after absorption and at various time intervals until all the liquid got evaporated from the aerogel sample. 5-4 A B' B C D Fig. 2. Schematic diagram of experimental set-up for the Young's modulus measurements of the silica aerogels, A: Vertical axis; B: Platform for the application of the stress; C: Silica aerogel cylinder; D: Flat bottom surface; l: Change in length after the application of the stress. 3. RESULTS AND DISCUSSION 3.1 Effect of MeOH/MTMS molar ratio (S) Change in length, l x 10-2 (m) 0.7 S = 35 0.6 0.5 S = 28 0.4 0.3 S = 21 0.2 0.1 0 0 10 20 30 40 50 60 70 Mass applied x 10-3 (kg) Fig. 3. Plots of change in length against mass applied for the silica aerogels prepared with various MeOH/MTMS molar ratios The effect of MeOH/MTMS molar ratio (S) on the elastic and other physical properties of the superhydrophobic silica aerogels was studied by keeping the molar ratio of H2O/MTMS constant at 8. The oxalic acid (C2H2O4) and ammonium hydroxide (NH4OH) catalyst concentrations were kept constant at 0.001M and 10M, 5-5 respectively. The Young's modulii (Y) of the aerogels scaled with the bulk density. It has been observed that with an increase in S value from 14 to 35, the volume shrinkage and hence the density of the aerogels decreased from 28 to 7% and from 100 to 40 kg/m3, respectively. Figure 3 shows the graphs of change in length against the mass applied for the calculation of Y. The Y was found to decrease from 14.11 x 104 to 3.0 x 104 N/m2 resulting in increase in the flexibility of the aerogels. Figure 4 shows the flexible aerogel sample which is bended about 90o (Figure 4a) and the extent of bending of the sample (Figure 4b). Since the silica chains of the aerogel with S = 35 are quite separated from each other and large empty spaces are available in the network, it can undergo deformation when the stress is applied. However, if the S value is decreased, i. e. for S = 14, the degree of polymerization increased and extensive cross-linking in three dimension resulted in the rigid structure. a b Fig. 4. a The flexible aerogel sample which is bended about 90o. b The extent of bending of the flexible aerogel sample. 3.2 Hydrophobicity and thermal stability of the aerogels The hydrophobicity of the aerogel sample was quantified by measuring the contact angles () of the water droplet placed on the aerogel surfaces under investigation shown in Figure 5. It was found that the aerogel sample was superhydrophobic with a contact angle of 175o for a 2.4 mm water droplet, since MTMS contains one hydrolytically stable methyl group, which is responsible for the hydrophobicity in the silica aerogels [12]. The photograph showing the water droplet placed on the surface of a superhydrophobic silica aerogel was depicted in Figure 6. Furthermore, the hydrophobicity was confirmed by the Fourier Transform Infrared (FTIR) spectrum shown in Figure 7 indicates strong peaks at 1270, 840 cm-1 and 2900, 1310 cm-1 corresponding to Si-C and C-H bonds respectively [13,14]. Very small peaks corresponding to O-H bonding around 3500 and 1650 cm-1 were observed, clearly indicating the hydrophobic nature of the aerogels. 5-6 h AEROGEL SAMPLE WOODEN SUPPORTING STAND Fig. 5. Schematic of contact angle measurement of the water droplet placed on the aerogel surfaces under investigation. Fig. 6. The photograph showing the water droplet placed on the surface of a superhydrophobic silica aerogel. 5-7 Fig. 7. The FTIR spectra of the MTMS based aerogel sample. Further, as shown in table 1, larger the R/Si ratio, the better is the hydrophobic covering yielding higher contact angles. However, in case of the MTMS, the contact angle is high though it is trifunctional. This is due to the fact that there is very less chances of formation of gel network using mono or di functional precursor. However, the trifunctional precursor gives three hydrolysable alkoxy groups to form the three dimensional gel network and one non hydrolysable alky group which led to the hydrophobic property of the final product. Table 1: Structure, silicon oxide content, R/Si ratio of the various functional groups. UnSi StructStruct ure Units ure MonofuMonofuncti DifuncDifunction TrifunTrifunctiona QuadriQuadrifunctio onal al l nal R R O O nctional tional ctional functional O O R R O O O O O O R O R R Si R SiO0.5 SiO SilicoSilicon oxide Si O1 SiO1 SiO (n = 0(n = 0 toContent 3)atio O Si SiO O 1.5 OSiO2 SiO1.5 0.5 Content R/Si RR/Si nRatio oxide O 3 2 TMES, TMCS, HMDZ DMCS 3 SiO2 2 DMCS 1 0 0 TEOS, TMOS 1MTMS, R= NonR= Non-hydrolysable TMCS, group, X= Hydrolysable group, to 3) It was found that for the superhydrophobic PTES silica aerogels, more Laplace -hydrolysable group,HMDZ X= Hydrolysable group, pressure (PL) is required to fill the water in the pores of the network according to the MTMS, following formula: PTES 5-8 PL = - 2 lv cos / (2) where lv is the interfacial energy of the liquid /vapor interface, is the contact angle of the liquid with the solid surface and r is the radius of the pore. Figure 8 shows the schematic diagram of Laplace pressure water intrusion. When applied pressure P is less than that of the Laplace pressure (PL), water can not enter into the pores and when P> PL , water enters the pores. Piston Fig. 8. Schematic diagram of Laplace pressure water intrusion. The Laplace water intrusion method indirectly provides an idea about the pore sizes as well as the hydrophobicity because the Laplace pressure is inversely proportional to pore size and directly proportional to the contact angle. 3.3 Transport of liquids on superhydrophobic aerogels Transportation of liquids on a nano scale is crucial in the development of nanofluid based devices for applications in chemical and biological technologies [15]. Therefore, the velocity of the liquid droplets on an inclined surface coated by the superhydrophobic silica aerogel powder has been studied using a specially prepared device interfaced with the personal computer as shown in Figure 9. The work of adhesion (Wa) values for various aerogel surfaces have been given in the table 2. The Wa values have been calculated using the Dupre’s equation: Wa = lv (1+ cos ) (3) where lv is the surface tension of the liquid (for water, lv = 72.99 N/m) [16]. Thus it can be observed from the values given in table 2, as the contact angle () increases (approaches to 180o) Wa becomes very small (Wa=0.54 N/m, for 173o) because of negligible interaction between solid-liquid phases. For complete non-wetting (=180o), Wa = 0, that is the drop would be levitated. 5-9 PC's parallel port + 5V 330 Water drop 47K 1M 2K LE D 1 13 47K Light detector 2 5 0 5 4 6 LM32 4 1 1 1 7 O/ P 1 4 Figure 9.a 1 4 t1 3 1 2 t2 2 Figure 9.b Fig. 9. a Circuit diagram of the instrument for the measurement of the droplet and marble velocities on an inclined surface. .b Schematic set up for water droplet velocity measurements: 1: Light emitting diodes (LED), 2: Photo-conductive detectors, 3: Inclined plane platform, 4: Water droplet (size: ~2.7 mm (0.2mm)). The aerogel powder was prepared by crushing the superhydrophobic aerogels. By rolling a water drop on the aerogel powder, liquid marbles were obtained. This aerogel powder covered water droplet (i.e. liquid marble) was placed on various substrates like glass, aerogel, paper, wood etc. It was observed that irrespective of the nature of the substrate, a small sized marble (~1mm) maintains its sphericity with 175o. However, a liquid marble placed on water deforms the water surface and hence the apparent contact angle decreases to 165o as seen from the Figure 10 which shows a typical liquid marble (2.7 mm (0.2mm)) floating on the water surface. 5-10 Table 2. Static contact angle () and velocity (v) of the water droplet on superhydrophobic aerogel coated surface for various angles of inclination. Sample M1 M2 M3 M4 M5 M6 Contact angle () 162o 160o 160o 159o 173o 162o Work of adhesion (Wa) mN/m 3.57 4.40 4.40 4.84 0.54 3.57 Drop centre deviation () cm 0.03 0.033 0.035 0.05 0.024 0.03 Inclination () v (cm/s) v (cm/s) v (cm/s) v (cm/s) v (cm/s) v (cm/s) 5o 28.16 29.14 19.25 40 29.6 40 15o 40 42.16 34 52 37.25 52.4 22o 42 67.75 43 70 60 77 35o 75.7 84.40 64.6 83.2 83.8 97.83 52o 96.75 105 92.6 97.83 97.83 144 Fig. 10. Liquid marble (2.7 mm (0.2mm) size) floating on a water surface. For the measurement of the droplet velocity on the superhydrophobic aerogel inclined plane, a droplet of the size ~ 2.7mm ( 0.2mm) was chosen because it is comparable to the capillary length -1 [17]: 5-11 -1 = (lv / g)1/2 (4) 3 For water, the surface tension lv = 72.99 N/m, the density = 1000 kg/m and the g= 9.8 m/s2. Hence the value of -1 is 2.7 mm. A droplet smaller than -1 generally remains stuck when placed on a solid surface because of the contact angle hysteresis. On the other hand, gravity would flatten a droplet of radius r > -1 [18]. The velocity of a freely falling water droplet of 2.8mm (0.2mm) size in the gravitation field was observed to be ~152 cm/s. The difference in the freely falling drop (~152 cm/s) and a rolling drop (highest v ~144 cm/s) indicates that a contact zone, however small, must be forming between the drop and the solid surface, which opposes the flow of liquid. It has been shown that, even for a small droplet of a liquid having contact angle 180o with a particular solid, a contact zone of radius 'l' forms between the solid and the liquid due to gravity [19]. The mass center of the droplet gets lowered by a quantity '' due its own weight. If 'r' is the radius of the drop, then the '' and 'l' are related to each other by: l2 (5) r The deviation () values observed for a water droplet of 2.8 mm (0.2 mm) placed on various aerogels are given in table 3. As the contact angle value increased from 159 to 173o, the value decreased from 0.05 to 0.024. Table 3. The velocity (v) of the liquid marbles on non-adhesive side of the tape (i.e. uncoated surface) for various angles of inclination. Sample M1 M2 M3 M4 M5 M6 Drop centre deviation () cm 0.026 0.028 0.030 0.027 0.024 0.024 Inclination () v (cm/s) v (cm/s) v (cm/s) v (cm/s) v (cm/s) v (cm/s) 5o 31.75 30 31 31.75 29.5 46.25 15o 35.25 38 37.3 39 38.4 60.5 22o 43.87 54 49.5 52 52 76.33 35o 57.66 82 70 66 73.75 105 52o 82.75 105 89.6 105 95 123.8 3.4 Uptake capacity of organic liquids by the superhydrophobic aerogels The uptake capacity of the aerogel sample was quantified in terms of the mass of the organic liquid absorbed by unit mass (1g) of the aerogel sample. For this study, various organic liquids were used which are shown in table 4. 5-12 Table 4. Mass of various organic liquids absorbed by unit mass (1g) of the aerogel sample. Organic Liquid / oil Mass of the organic liquid / Moles of the organic oil absorbed per unit mass liquid absorbed per unit mass (1g) of the aerogel (1g) of the aerogel Pentane 9.83 g 0.1365 Hexane 10.95 g 0.1215 Heptane 13.38 g 0.1338 Octane 13.82 g 0.1210 Benzene 19.92 g 0.2553 Toluene 20.64 g 0.2189 Xylene 20.37 g 0.1921 Methanol 14.03 g 0.4410 Ethanol 14.54 g 0.3231 Propanol 19.15 g 0.3191 Butanol 18.93 g 0.2558 Petrol 13.82 g ----- Kerosene 16.45 g ----- Diesel 18.55 g ----- From the table, it follows that the mass of petrol absorbed was minimum (13.82g) and diesel was maximum (18.55g) among the oils. The aerogel absorbed nearly the same amount (~20g) of the solvents benzene, toluene and xylene. Among the alkanes, the mass of pentane absorbed was minimum (9.83g) while the mass of octane absorbed was maximum (15.62g) and among the alcohols, the mass of methanol absorbed was minimum (~14g) and that of butanol was maximum (~19g). The mass of the organic liquid absorbed by an aerogel depends upon the surface tension () of the corresponding liquid. From the Young’s equation [20]: SV = SL + LV cos …….... (6) where SV is the solid-vapour, SL is the solid-liquid and LV is the liquid-vapour interaction at the intersection of the three phases, it follows that the MTMS based superhydrophobic (>150o) silica aerogels are low energy surfaces which are not wettable by water. But the organic liquids wet the surface and also get absorbed by the aerogels. This is due to the fact that the organic liquids are less polarizable than the solid aerogel. Table 4 also gives the moles of solvent absorbed per unit mass of the aerogel. The oils such as petrol, diesel and kerosene being the extracts from the crude oil, the molecular weights are not well defined and hence the moles of the oils absorbed is not 5-13 given in the table. It is interesting to note that the graph of desorption time versus the moles of solvent absorbed per unit mass of the aerogel is linear for all the three types of solvents- alkanes, aromatics and alcohols as shown in Figure 11. 200 Alkanes Aromatics Alcohols 150 Desorption time (min) 100 50 0 0 0.1 0.2 0.3 0.4 0.5 Moles of solvent per unit mass of the aerogel Fig. 11. Desorption time of solvents as a function of moles of solvent absorbed per unit mass of the aerogel. 3.5 Rate of desorption of organic liquids by the superhydrophobic aerogels The rate of desorption was found by measuring the mass of the aerogels at regular time intervals till the liquid got totally evaporated and the original mass of the aerogel was restored. Figure 12 shows the photographs showing various stages of absorption and desorption of hexane from the aerogel. It was observed that the rate of desorption was very high at the beginning and slowed down with the passage of time. Further, it was observed that the desorption rate decreased as we go from shorter chain (pentane) to the longer chain (octane) organic liquids. This is due to the fact that the process of evaporation takes place in two stages. During the first stage, molecules are brought from the interior up to the surface, overcoming the surface tension effect and during the second stage, they vaporize from the surface film depending on the vapor pressure of the liquid. Therefore, lesser is the surface tension, easier for the molecules to come on to the surface and hence faster would be the evaporation. 5-14 Figures 13 show the transmission electron micrographs of the aerogels before absorption and after desorption of methanol. Fig. 12. The Photographs showing various stages of absorption and desorption of hexane from the aerogel. a b Fig. 13. Transmission electron micrographs of the aerogels before absorption and after desorption of methanol. 3.6 Effect of temperature on desorption of organic liquids by the superhydrophobic aerogels To study the effect of temperature on the rate of desorption, after absorption, the samples were put in an oven (Termaks company, Norway) at various temperatures and the desorption time was recorded. Figure 14 shows the effect of temperature on the desorption time of petrol. It was observed that with an increase in temperature, the desorption time decreased significantly. Desorption time for butanol, for example, reduced from 180 minutes at 30oC to 14 minutes at 100oC. Similarly, for octane, it reduced from 80 minutes at 30oC to 8 minutes at 100oC. 5-15 700 Desorption time (min.) 600 500 400 300 200 100 0 20 40 60 80 100 120 o Temperature ( C) Fig. 14. Desorption time of petrol as a function of temperature. With an increase in the temperature, the vapor pressure of the organic liquids increases considerably. For e.g., the vapor pressure of methanol at 30oC is 209.67mm of Hg, while it is 416.58mm of Hg at 50oC. The surface tension of all the liquids decreases linearly with the rising temperature, over small temperature ranges, so that the surface tension, t, at toC is given by [21]: t = o (1-t) …….... (7) where o is the surface tension at 0oC and is the temperature co-efficient. As a result, it would be easy for the liquid molecules to come out of the aerogel pores at higher temperatures due to higher temperature gradient. At the same time, with an increase in temperature, the vapor pressure increases leading to the early evaporation of the liquid from the aerogel surface. Therefore, desorption time decreased remarkably with the increase in temperature. 4. CONCLUSIONS The physicochemical properties of elastic superhydrophobic silica aerogels have been studied. Also, use of as prepared aerogel in absorption and desorption of the organic liquids and oils have been studied. The following are the major findings of the present experimental investigations: 1. Highly flexible and superhydrophobic silica aerogels have been obtained using MTMS precursor. 2. The aerogels regain its origin shape after releasing the stress. 5-16 3. The powder of the aerogel sample cab\n be used to produce liquid marbles, which float on the water surface. 4. The aerogel absorbed the organic liquids and oils by nearly 15 times its own mass. 5. The aerogels retained their original structure after the total desorption of the organic liquids. 6. The rate of desorption increased with an increase in the temperature. Thus, the elastic superhydrophobic aerogels could be used as efficient absorbents for the purposes of storage, clean-up, transport and the safe disposal of organic liquids and oils. REFERENCES 1. L. W. Hrubesh, Chem.Ind.17 (1990) 824. 2. Bond G. C. and Flamerz S., Appl. Catal., 33 (1987) 219. 3. J. Fricke, A. Emmerting, Structure and Bonding, 77 (1992) 27. 4. C. A. M. Mulder, J. G. Van Lierop, in: J. Fricke (Ed) Aerogels, Springer, Berlin, 1986, p.68. 5. Pestotnik R, Krizan P, Korpar S, Bracko M, Staric M, Stanovnik A, Nuclear Science Symposium Conference Record, 2001IEEE1 (2001) 372. 6. K. Y. Jang, K. Kim, R. S. Uphadye, J. Vac. Sci. Technol, A 8 (1990) 1732. 7. R. Alfaro, M.I. Martínez and G. Paic, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 572 (2007) 437. 8. M. Reim, W. Körner, J. Manara, S. Korder, M. Arduini-Schuster, H.-P. Ebert and J. Fricke, Solar Energy, 79(2005) 131. 9. A. Venkateswara Rao, Manish M. Kulkarni, Sharad D. Bhagat, J. Colloid Interface and Sci., 285 (2005) 413. 10. Jun Li, Xianyou, Qinghua, Sergio Gamboa, P.J. Sebastian, J. Power Sources, 158 (2006) 784. 11. Qanil Tang, Yao Xu, Dong Wu, Yuhan San, Jiqing Wang, Jun Xu, Feng Deng, J. of Controlled Release 114 (2006) 41. 12. A. Venkateswara Rao, M. M. Kulkarni, D. P. Amalnerkar, T. Seth, J. Non-Cryst. Solids, 330 (2003) 187. 13. N. Hering, K. Schriber, R. Riedel, O. Lichtenberger, J. Woltersodorf, Appl. Organometal. Chem. 15 (2001) 879. 14. M. Laczka, K.Cholwa-Kowalska, M.Kogut, J.Non-Cryst. Solids 287 (2001)10. 15. J. P. Rolland, R. Van Dam, D. A. Schorzman, S. R. Quake, J. M. DeSimone, J. Am. Chem. Soc. 126 (8) (2004), 2322. 16. A. Venkateswara Rao, G. M. Pajonk, N. N. Parvathy and E. Elaloui, in: Y. A. Attia (Ed.), Sol-Gel Processing and Applications, Plenum Press, New York, 1994, p. 237 17. A. Venkateswara Rao, M. M. Kulkarni, Mater. Res. Bull., 37 (2002) 1667. 18. A. Venkateswara Rao, R. R. Kalesh, D. P. Amalnerkar, T. Seth J. Porous. Mater. 10 (2003) 23. 19. D. A. Fridrikhsberg, "A Course in Colloid Chemistry", Mir Publishers, Moscow, 1986, p. 63. 20. Arthur Beiser, The Mainstream of Physics, Addison Wesley Publishing Company Inc., second printing, 1962, p-124. 21. F.H. Newman and V.H.L. Searle, The General Properties of Matter, Orient Longmans, Fifth Edition, 1957, p.188. 5-17