SPECIFICATION CHOICE MATRIX ECO

advertisement

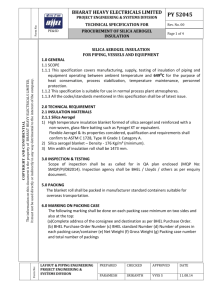

SPECIFICATION CHOICE MATRIX ECO-HOUSE: QUALITY KING ELEMENT: EXTERNAL WALLS PRODUCT: PROCTORS SPACETHERM-F AEROGEL INSULATION BOARD SCORING PERFORMANCE COST BUILDABILITY SCORE LIFECYCLE/ MAINTENANCE COSTS EMBODIED ENERGY ENVIRONMENTAL IMPACT PRACTICAL USAGE BY OCCUPANT SCORE SCORE (OUT OF 10) 9/10 1/10 3/10 55% 9/10 6/10 5/10 8/10 70% TOTAL PERCENTAGE SCORE 63% WEIGHTING 50% 25% 25% 0% 0% 0% 0% ANALYSIS: Aerogels are very low density solid state materials derived from gel in which the liquid component of the gel has been replaced with gas. Produced from silica dioxide (silica) they are the world’s lightest solid and their insulating properties make them unbeatable in terms of performance. The thermal conductivity of aerogel silica is typically 0.018W/m²K at 10 degrees C. Aerogels also have a very high compressive strength. Proctor’s Spacetherm-F Aerogel insulation board comprises a layer of matting within which particles of aerogel are dispersed. The matting is glued to a layer of particle board which forms the internal surface of the room. Spacetherm board with three layers of 10mm matting and a 25mm air gap can reduce the U-value of a solid brick wall to 0.33W/m²K. The cost of the product to this specification would be £169.89 per m². The width of the air, gap, particle board and matting combined would be 65mm, however, if the services are surface run, then Proctors supply particle board or 9.5mm bonded onto ply wood and the product. A layer of foil in-between either the particle or plaster board helps mitigate interstitial condensation and no vapour barrier is required. The lead in time is 5-7 working days. Proctors provide a one day training course for the installation of the product at a cost of £500. There is a Fermacell guide available on appropriate fixings for the wall. Nailing/screwing into the wall should be no more difficult than with plaster. Any breaches in the insulation will reduce the thermal resistance of the product. The embodied CO₂ in Spacetherm is 4.2 (kg of CO₂ per kg)⁴. Spacetherm can be difficult to cut and handle and the dust can irritate the eyes, skin and respiratory tract. The product would need to be cut before being fitted to the walls to accommodate socket outlets. This will have some effect on the thermal performance of the product. The team discussed options of overcoming this such as avoiding sockets on the external walls or using skirting that contains trunking. The question of whether the residents would be able to fix appliances such as televisions to the wall was raised. It was assumed at this stage that this would be possible although the manufacturer would need to confirm this. The product cannot be recycled and it is non-biodigradable. The manufacturer can provide cold bridging strips for application where maximum performance and minimum thickness is required.