Spiral Vortices Detection on Rotating Disk

advertisement

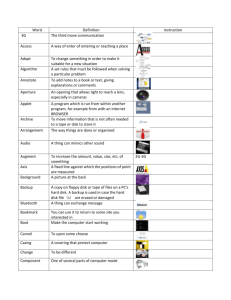

Spiral Vortices Detection on Rotating Disk T. Astarita and G. Cardone and G. M. Carlomagno University of Naples - DETEC P.le Tecchio, 80 - 80125 Naples, ITALY Tel. +39 81 7682178; Fax +39 81 2390364 The thermal efficiency of gas turbine engines strongly depends on the gas entry temperature; the higher this temperature, the more efficient is the turbine thermal cycle. Present advanced gas turbines operate at gas entry temperatures much higher than metal creeping temperatures and therefore require intensive cooling of their blades and disks especially in the first stages. The presence of spiral vortices in the transitional regime of the three-dimensional boundary layer on a disk rotating in still air has received a considerable attention in the past due to both theoretical relevance and practical applications. A sketch of the experimental apparatus is shown in the following figure. The disk section consists of a 450mm in diameter light-alloy steel cup filled with 20mm thick polystyrene on which a printed circuit board is glued. The circuit is used to generate, by Joule effect, a uniform heat flux on the disk surface, while the polystyrene thermally insulates the face of the disk not exposed to air. Electric power is supplied to the printed circuit by means of a mercury rotating contact. A pulley, that is connected by a transmission belt to an electric motor, is fixed on the transmission shaft supporting the disk. The disk rotating speed can be varied in a continuos way within the range 1002000rpm. Sketch of the experimental apparatus. The printed circuit board is designed so as to achieve a constant heat flux over the disk surface and therefore the thickness and the width of its conducting tracks, having a spiral shape, are manufactured with very close tolerances. Tracks are 35m thick, 2mm wide and placed at 2.5mm pitch; the overall thickness of the board is 0.2mm. To enhance the emitted IR radiation detection, the measured board surface is coated with a thin layer of black paint which has an emissivity coefficient equal to 0.95 in the working IR window of the employed scanner. The infrared thermographic system employed is the AGEMA Thermovision 900. The field of view (which depends on the optics focal length and on the viewing distance) is scanned by the Hg-Cd-Te detector in the 8-l2m infrared window. Nominal sensitivity, expressed in terms of noise equivalent temperature difference, is 0.07 °C when the scanned object is at ambient temperature. The scanner spatial resolution is 235 instantaneous fields of view per line at 50% slit response function. In order to detect the spiral vortices attached to the disk surface, the line scan option of AGEMA Thermovision 900 IR camera is used to take temperature profiles along one radius as a function of time at thermal steady state. Since the disk is rotating, it is possible to reconstruct the temperature map on the surface of the disk by taking into account the rotation of the latter. A typical example of this reconstruction, which is made by superimposing about 30,000 radial profiles, is represented in the following figure. The spiral vortices are clearly evident in the figure and their number and inclination, with respect to the radial direction, well agree with previous values reported in the literature. Spiral vortices on a rotating disk. An application software, that is based on Fourier analysis and correlation of temperature profiles along circumferences, enables to precisely count the vortices and evaluate their inclination as a function of the local Reynolds number Rer. The following figure shows the number of vortices as a function of the local Reynolds number. It is possible to note that for a Rer of about 200,000 the number of vortices doubles i.e. a bifurcation occurs. Number of vortices versus local Reynolds number