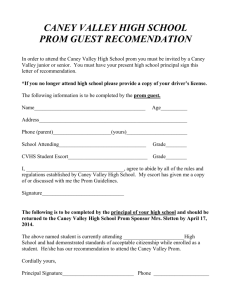

Caney Shale Gas Workshop

advertisement

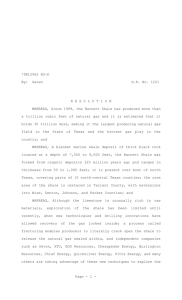

Caney Shale Gas Workshop (August 2006) With ⅓ of the United States’s natural gas supply projected to be tied up in gas shales by 2014, gas shales have been termed the next “big” onshore play in the United States. Once viewed only as source rocks, organic-rich shales are now receiving attention as reservoir rocks. How to better understand these rocks and gain access to their valuable hydrocarbon resource was the main theme of this workshop, with special emphasis given to the Caney Shale in Oklahoma. The Mississippian-age Caney is geologically equivalent to the Barnett Shale in north Texas and the Fayetteville Shale in Arkansas. In an overview of the Caney, the first of six speakers stepped through the tectonic changes and subsidence history that led to present day distribution of the Caney. In the Arkoma Basin, the main area of interest, the Caney is stratigraphically uniform, thickening only where stacking of thrust sheets aggregates the layers. Throughout Oklahoma there are 58 Caney (frequently reported as “Mississippian”) gas shale wells, including 9 horizontal. Isopach maps of 6 Caney Shale subdivisions were described for a 22x9-township region extending from central Oklahoma into the deep Arkoma Basin. Vitrinite reflectance and Tmax measurements show the Caney is a very cooked rock. Basin modeling indicates it went through the oil window before the end of the Pennsylvanian, with later heating cracking the oil to gas. Acid treating is preferred over fraccing to create porosity. A preferred horizontal well profile involves first setting pipe in an angled sump hole and then kicking off laterals. “Mining” information from logs can be worthwhile. Plotting Vp/Vs ratios from sonic logs – a “poor man’s seismic turned on its side” – vs. neutron density, gas saturation, and bulk water porosity can help differentiate between water-wet and gas-bearing shales. This idea is based on the intrinsic acoustic anisotropy of shales. Processing signals of gamma ray logs through wavelet analysis is a possible approach for measuring sedimentation rates. An important technological advance in gas shale exploration, in addition to improved fracturing techniques and horizontal drilling, is the use of geochemical data to delineate productive zones. Geochemists define and measure quantity of TOC (total organic matter), type of organic matter (kerogen), thermal maturity, free gas vs. sorbed gas, and stable isotopes to help predict prospective areas for the explorationist. Details of these measurement processes and their limitations were summarized by the third speaker. Evaluation of a shale gas reservoir involves delineating the bed, quantifying adsorbed and free gas, determining producibility of the system, and predicting production. Computerized wireline evaluation techniques can perform these tasks. Based on a set of interpretation models, the software solves simultaneous equations using data from downhole logs. The speaker discussed applying the program to solve for adsorbed and free gas content (GIP) as well as generating input for frac designs and production simulators. The two most important messages from a talk on horizontal drilling were that horizontal directional drilling expertise is area specific and extensive pre well planning between client and drilling company is required. Other topics included well design options, how the accuracy of survey tools affects wellbore uncertainty, bottom hole assemblies, rig requirements, lateral length (Generally, 2000 feet or less is the best risk even though longer lengths generate more excitement.), and new technology. A formation boundary detector that looks at formations ahead of and around the bit sounds promising. Older Caney production in Oklahoma is from vertical wells but more recent completions are horizontal. As with the Barnett, cased cemented multi-stage fracs are the predominant completion method. The number of frac stages used in the Caney is 3 or 4. Other completion types common in the Barnett have not yet been applied to the Caney. The use of reactive stimulation fluids in place of conventional water frac treatments appears to significantly increase initial production in the Caney.