Nitric Acid - Acetic Acid (HNA) Silicon Thinning

advertisement

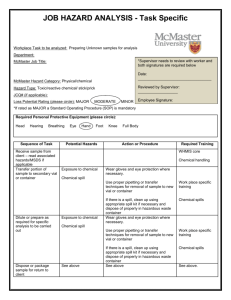

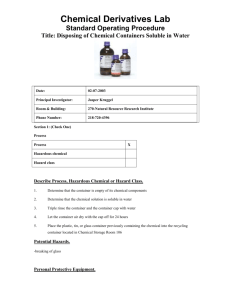

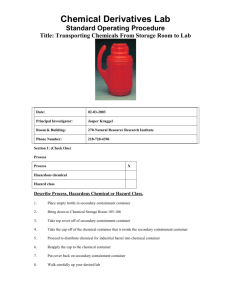

UC Irvine Environmental Health & Safety: Example Standard Operating Procedures for 1:3:8 HNA Solution #1 #2 #3 #4 #5 #6 Process pH solutions. Hazardous Properties/Exposure Symptoms Corrosive. Severe burns. Fever, cough, dyspnea, cyanosis, pulmonary edema, blood spitting. Latency period up to 2 days. PPE - Personal Protective Equipment Skin and eye protection. Wear impervious protective clothing. Neoprene, natural rubber, nitrile, Silver Shield. LDPE storage bottle and Teflon carrying container that holds 3x the volume of the storage bottle capable of fully containing a chemical spill. Avoid inhalation of fumes. Users will wear clean room coverall garments, extra length chemical gloves and full face shield. All HNA activities must be carried out at an exhausted acid cabinet with calcium gluconate antidote gel nearby. Engineering/Ventilation Controls Always use in an exhausted acid cabinet. Always use in area equipped with an emergency shower and eyewash. Special Handling Procedures and Storage Requirements Read MSDS prior to use. Containers should tightly closed and stored in a cool, dry, well ventilated area away from incompatibles including glass, most metals, arsenic trioxide, calcium oxide, phosphorus pentoxide, mercury oxide, nitric acid, sulfuric acid, sodium, sodium or potassium tetrafluorosilicate, nphenyl azopiperidine. Place storage bottle into the clean Teflon carrier at the designated area in the Clean Room. Transport solution to third floor lab. Contact with water releases corrosive fumes. Do not store with flammables. Place containers in trays to contain any accidental spills while in storage. Be mindful of leak evident label ink that changes from blue to yellow should the outside of the bottle become contaminated with HNA. Store in HNA cabinet in room ________. Spill and Accident Procedures Small spills: Do not attempt clean-up if you feel unsure of your ability to do so or if you perceive the risk to be greater than normal laboratory operation. Use neutralizer found in Acid Spill Bucket. Collect residue and contaminated wipes into waste container. Label and transfer to EH&S for disposal. Contact Facility Manager for site assessment. Large Spills: Notify others in the area. Evacuate room and notify EH&S. First Aid: Remove contaminated clothing and shoes. Get medical attention immediately. Eyes: wash eyes immediately with large amounts of water, occasionally lifting upper and lower lids, at least 15-20 minutes. Skin: wash affected area with soap or mild detergent and large amounts of water for five minutes. Apply calcium gluconate gel by rubbing it gently into the affected area. Inhalation: remove to fresh air immediately. Keep warm and at rest. #7 Waste Disposal Place waste in labeled container with hazardous waste tag complete. Store in secondary container in Hazardous Waste Storage Area under hood in Room ___. Dispose of through EH&S within 90 days of container start date or when 1 quart volume is reached. #8 Approval Required HNA shall not be brought into the lab without prior approval from the Facility Manager. #9 Decontamination Procedures Contaminated areas should be neutralized and cleaned thoroughly using the materials found in the Acid Spill Bucket. All waste generated in this process should be placed in hazardous waste containers and labeled to indicate the presence of hydrofluoric acid. #10 Designated Area Use in Clean Room marked for HNA work. For more information relevant to completing this form, review thoroughly Chemical Hygiene Plan: Section 5. Also review Procedure HNA01- Level 1 Etch for more process information. Training Acknowledgement: I have read, asked questions, and understand the hazards of and safe working procedures for the activity/materials described herein. NAME DATE UC Irvine Environmental Health & Safety: Example These safety training resources, prepared solely for the use of the Regents of the University of California, were provided by a variety of sources. It is your responsibility to customize the information to match your specific operations. Neither the University of California nor any of its employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the University of California. The views and opinions of authors expressed herein do not necessarily state or reflect those of the University of California, and shall not be used for advertising or product endorsement purposes.