Using the Tree Diagram to Improve Complex Projects

advertisement

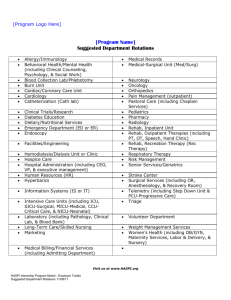

Using the Tree Diagram to Improve Complex Projects Earlier in the chapter we discussed the use of the tree diagram for planning (see Figure 213). In this section we will discuss using the tree diagram for breaking down complex improvement projects. The first tree diagrams presented will employ the questions from the Model for Improvement for guidance in breaking down the project from the aim of the project to questions that can lead to possible improvement cycles. We will then conclude this discussion with a healthcare example that employs the use of the Planning type tree diagram over the time of the project. This example will show how improvement concepts can be developed into potential changes that will lead to a desired vision developed by an improvement team. Examples of the Tree Diagram Integrating the Model for Improvement to Address Complex Projects Figure 21-7 has been borrowed from the Improvement Guide to show the complexity of various types of improvement efforts from the very simple to the most complex. For the next example of using the Tree Diagram we will focus on an example that is aimed at improving a process to gather data from sales within an organization. Figure 21-7: Complexity of Level of Various Improvement Projects – Focus is on Improving a Process in an Organization The tree diagram depicted in Figure 21-8 generally follows the flow of the Three Questions in the Model for Improvement: 1. What are we trying to Accomplish? General Description Project Objectives describe objectives to support the overall general description and the answer to question one. In this example we are trying to “Improve the process by which we gather data from the product sales force…” Using the Tree Diagram to Improve Complex Projects © API/September 2006 1 2. How will we know that a change is an improvement For each objective, a measure(s) is selected to answer question two in the Model for Improvement. Identifying measures related to the objectives usually provides some intermediate measures for the project (see Improvement Guide p.55). 3. What changes do we need to make? For this question, questions are posed that need to be answered by the people leading the project. These questions can lead to appropriate PDSA cycle. Also added are appropriate Change Concepts (Reference: Improvement Guide, p. 295) that can lead to changes and ideas that can be tested immediately. Figure 21-8: Tree Diagram Using the Three Questions to Improve a Sales Process 1 .What are we trying to accomplish? 2 .How will we know a change is an improvement? Improvement Objectives / Measures Describe Project: (check one) _ X_ Redesign existing Process(es), product or service ___ Design new process(es), Product or service ___ Improve the system as a Whole (mainstay, drivers & support processes) Create request process & measures M - Process utilization rate (Collect data) 3. What changes can we make that will lead to improvement? Questions to Answer Change Concept/ Ideas How do we make it easy for people to engage the team to deliver surveys? B14 / Implement a request form and web link How do we measure the resources needed to support the process? D28 / Implement a measurement process & report How do we assess whether a survey is needed or not with the existing Time Analysis survey in place & other data collected? A9, D34, D27, G53 / Engagement guidelines to assess survey needs Brief Description: (include description above) Improve the process by which we gather data from the Product Sales Force & increase knowledge retention of key sales performance indicators (time spent, satisfaction, etc…) consistently through a single point of capture. What alternate methods can we advise the internal partner to use? M - # of Surveys Received by Sales, & Time Spent on Surveys (Collect data) How is the outcome tracked, monitored and used for questions asked? B18, E38 / Communicate responses Sales: Have the decision makers heard the sales feedback? E42 / Communicate change based on feedback Standardize the survey launch process M – Client satisfaction (Collect data) To create cadence in the sales work week how do we create consistency? How do we draw new clients into the process? How do we ensure consistent delivery of the survey process? Items in Green Engagement guidelines to advise partners Improving sales data collection & usage answer the question “What can we do right now?” A5, B20, G51, I68 / Widespread executive sponsorship for a single process H59, F46 / Develop a checklist for survey launch – Using the Tree Diagram to Improve Complex Projects © API/September 2006 2 Figure 21-9: Planning Chart Using Action Items from the Tree Diagram PDSA Cycles & Activities Implement Request Form Implement Measures Develop Guidelines Test Guidelines Implement Guidelines Develop Process for Responses Test Response process Implement Response Process Survey Decision Makers Standardize Survey Process Test Survey Implement New Survey Process Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 Week 7 Once the tree diagram is detailed to a useful state, the actions associated with Question Three of the Model for Improvement can be placed in time order. Figure 21-9 describes the flow of the various action items and PDSA cycles developed from the questions that need to be answered in the project and potential changes developed by consideration of the Change Concepts (Reference: Improvement Guide, p. 295). The tree diagram can also be used to scope large complex projects that would have multiple application of the Model for Improvement. Figure 21-10 shows the relative position of our next example as improvement of a subsystem for sales support within a large international corporation. As we focus on the tree diagram in Figure 21-11, we see that each of the objectives is large enough to incorporate an improvement effort for each objective. In this organization, the term “Charter” is reserved for a document that will guide the deployment of several “Improvement Plans.” Figure 21-12 describes this breakdown of individual improvement objectives at the Charter level to four individual Improvement Plans. All efforts are being guided by the Model for Improvement. Figure 21-10: Complexity of Level - Focus is on Improving a Subsystem Using the Tree Diagram to Improve Complex Projects © API/September 2006 3 Week 8 Figure 21-11: Tree Diagram Using the Three Questions to Improve the Sub-system for Technical Support within a Large Technology Company 1. 2. How will we know a change is an improvement? What are we trying to accomplish? General Description of Project Describe Project: 1. (check one) ___ Redesign existing Process(es), product or service ___ Design new process(es), Product or service _X_ Improve the system as a Whole (mainstay, drivers & support processes) Brief Description: (include description above) Provide a differentiated customer experience for strategic customers, and a more basic experience for non-strategic. (reduce over-delivery) M: cost/incident, vol. self-solve vs. assisted solve 2. Improve the system for technical support, reducing costs while maintaining customer satisfaction. FY06 Strategic objectives specifically target $15M in cost reduction to improve GM% by 11%. The majority of the cost reduction is targeting in the mainstay of the system. Questions to Answer (Potential Cycles) Project Objectives M: CSI/top 20 in region M: CSI for non-top in reg. 3. Improve the “self-solve” web capabilities (greater coverage across products for knowledge, patches, upgrades, defect management) shifting away from resources for assisted solve M: reduced cost/case, reduced variation per supplier Reduce supplier cost/case for assisted solve from partners, contractors and 3rd parties. 4. M: reduced cost/case, cost attribute per classification Reduce support costs for older versions of products, low GM% accounts, cost of supporting products with high defects 3. What changes can we make that will lead to improvement? What knowledge is most useful? How does it affect resolution of customer case (should be 2x faster, if not a defect)? Does customer has better experience? What system(s) are most useful for capturing customer knowledge? How should the process and system use be deployed? What are measures of effectiveness of this process relative to the overall system? What gaps in current KM are most needed to improve the customer’s self-solve usage? What process changes are needed to ensure we fulfill those knowledge gaps initially and ongoing? What costs are involved in the fulfillment of the knowledge gaps and how does this impact the overall delivery of service to customers? What measures are needed to ensure we maintain an effective system of delivery for both assisted and self-solve processes? What are the variations in supplier costs/case and what are some of the main reasons for these? What opportunities do we have for improving the system by which suppliers provide service/ support on our behalf, esp. to reduce average costs? Which older product versions (>n-2) have the greatest impact on support delivery cost/call today? What are the reasons? Which accounts have the greatest impact on cost/ call and overall costs (GM), and what are the reasons? What products currently have high defect rates that are impacting costs, and what steps are needed to reduce the impact of these? Possible Change Concepts to Apply 16. Find & remove bottlenecks 27. Give people access to information 40. Focus on outcome for a customer 7. Reduce classifications 9. Match amount to the need 11. Change tgts / set points (SLO) 40. Focus on the outcome for a customer 39. Coach customer to use product / service 43. Outsource for “free” suppliers provide knowledge 51. Standardization of processes 45. Work with Suppliers 16. Find & remove bottlenecks 45. Work with suppliers (CPE partners) 39. Coach customer to use product/service (training, KP, NRCE) Figure 21-12 describes how the project was managed using a Charter to guide four Improvement Plans. The project measures were connected to the overall charter. For each of the four objectives it was deemed appropriate to have a separate Improvement Plan to guide the effort. The Model for Improvement was then used to manage and coordinate the overall project. Using the Tree Diagram to Improve Complex Projects © API/September 2006 4 Figure 21-12: Tree Diagram Using the Three Questions to Improve the Sub-system for Technical Support within a Large Technology Company Improvement Plan 1 General Description of Project M: CSI/top 20 in region M: CSI for non-top in reg. Describe Project: (check one) 1. ___ Redesign existing Process(es), product or service ___ Design new process(es), Product or service _X_ Improve the system as a Whole (mainstay, drivers & support processes) Brief Description: (include description above) Improve the system for technical support, reducing costs while maintaining customer satisfaction. FY06 Strategic objectives specifically target $15M in cost reduction to improve GM% by 11%. The majority of the cost reduction is targeting in the mainstay of the system. Questions to Answer (Potential Cycles) Project Objectives Provide a differentiated customer experience for strategic customers, and a more basic experience for non-strategic. (reduce over-delivery) What knowledge is most useful? How does it affect resolution of customer case (should be 2x faster, if not a defect)? Does customer has better experience? What system(s) are most useful for capturing customer knowledge? How should the process and system use be deployed? What are measures of effectiveness of this process relative to the overall system? Possible Change Concepts to Apply Model for Improvement 16. Find & remove bottlenecks 27. Give people access to information 40. Focus on outcome for a customer What are we trying to accomplish? Improvement Plan 2 How will we know that a change is an improvement? Model for Improvement 7. Reduce classifications 9. Match amount to the need 11. Change tgts / set points (SLO) What change can we make that What will are we trying to result in improvement? accomplish? Improvement Plan 3 How will we know that a change is an improvement? M: cost/incident, vol. self-solve vs. assisted solve 2. Improve the “self-solve” web capabilities (greater coverage across products for knowledge, patches, upgrades, defect management) shifting away from resources for assisted solve 3. M: reduced cost/case, reduced variation per supplier Reduce supplier cost/case for assisted solve from partners, contractors and 3rd parties. 4. M: reduced cost/case, cost attribute per classification Reduce support costs for older versions of products, low GM% accounts, cost of supporting products with high defects Model for Improvement Act What change can we make that Plan What gaps in current KM are most needed to improve the customer’s self-solve usage? What process changes are needed to ensure we fulfill those knowledge gaps initially and ongoing? What costs are involved in the fulfillment of the knowledge gaps and how does this impact the overall delivery of service to customers? What measures are needed to ensure we maintain an effective system of delivery for both assisted and self-solve processes? What are the variations in supplier costs/case and what are some of the main reasons for these? What opportunities do we have for improving the system by which suppliers provide service/ support on our behalf, esp. to reduce average costs? Which older product versions (>n-2) have the greatest impact on support delivery cost/call today? What are the reasons? Which accounts have the greatest impact on cost/ call and overall costs (GM), and what are the reasons? What products currently have high defect rates that are impacting costs, and what steps are needed to reduce the impact of these? 40. Focus on the outcome for a customer 39. Coach customer to use product / service 43. Outsource for “free” suppliers provide knowledge 51. Standardization of processes What are will we trying result to in improvement? accomplish? Improvement Plan 4a How will we know that Study change is an improvement? Do Model for Improvement Act What change can we make thatPlan What will are we trying to result in improvement? accomplish? System Measures How will we know that Study a change is an improvement? 45. Work with Suppliers 16. Find & remove bottlenecks Do Act What change can we make that Plan will result in improvement? 230 210 190 J M M J S N J M M J S N J M N J M M J S N J M M J S N Study 95 90 85 80 75 45. Work with suppliers (CPE partners) J M M J S 39. Coach customer to use product/service (training, KP, NRCE) 15 M J S Act Plan Study Do N Do 10 5 0 J M M J S N J M M J S N J M M J S J M M J S N J M M J S N J M M J S N J S N Overall System Charter N 15 10 5 0 35 25 15 5 J M M J S N J M M J S N J M M Using the Planning Type Tree Diagram to Guide a Complex Project in Healthcare The tree diagram in Figure 21-13 describes the use of “planning” type tree diagram to guide a project towards accomplishing a desired vision. In this diagram we have four concepts that are driving the current changes. From these current changes, potential changes have been identified that will be necessary to move the overall effort to the desired vision. Figure 21-14 describes a project in a Healthcare system where changes are being developed, tested and implemented to improve the relationships between healthcare professionals and patients. The team started off with several guiding principles: You Know Me; Changes to establish the relationship with the patient The Care Team; Changes to be made by key contacts in the care team Collaboration; Changes to better understand and work with the patient Options and Tools; Methods and Tools to enhance communication and the relationship. Using the Tree Diagram to Improve Complex Projects © API/September 2006 5 From these concepts, changes known to the team were identified that could be tested now. As the team developed and tested and these changes, other potential changes were identified. In addition to this thought process, the team used the overall vision to develop other potential changes that would be required to move the team to accomplishing their vision. As the team developed the plan for these changes they also included a timeline to forecast when the changes could be integrated into the system. Figure 21-13: Using the Planning Type Tree for Planning Changes Over Time Directed to a Desired Vision in Healthcare – Conceptual Example Concept • Current Change • Concept • • Current Change • Concept • Potential Change • Potential Change • Potential Change Planned Change Current Change • • Concept • Planned Change Potential Change Team Vision The team’s vision/ personalizatio n of the concept design Planned Change Current Change TODAY Mar. 2006 3 Mos. June 2006 6 Mos. Sept. 2006 9 Mos. Dec. 2006 12 Mos. PROJECT TIMELINE Using the Tree Diagram to Improve Complex Projects © API/September 2006 6 Figure 21-14: Using the Planning Type Tree for Planning Changes Over Time Directed to a Desired Vision in Healthcare – Detailed Example You Know Me • Care Team • • • • Collaboration • • • Options/Tools • • • Kp.org sign-up kiosks & info Patient contact preferences Nickname in header Receptionist colocated with team CA reviews after visit summary with patient RN pre-screening charts Proactively identifying patient needs Reaching out to patient and subsequent followup Telephone visits •Pre-visit prep with patients to elicit what matters • New roles for members of the care team based on the work • Ask patients to do collaborative goal setting during visit • Build Care plan into chart – consistent place • Virtual visits with agreeable members • New members of the care team based on the work • Action plans based on evidence-based care developed with patients • e-visits as the standard mechanism for follow-up • What matters to patient addressed by care team • Collaborative care plan guides all interactions • Panel View tool to manage patients The care team, supported by optimizing the relationshipbased care of a population of patients Group visits Health Assessments TODAY Mar. 2006 3 Mos. June 2006 6 Mos. Sept. 2006 9 Mos. Dec. 2006 12 Mos. PROJECT TIMELINE Summary This paper has discussed several key points related to using tree diagrams to breakdown complex improvement projects: 1. The Model for Improvement and use of the Three Questions can be used in conjunction with the Tree Diagram to break down improvement projects. 2. Obvious PDSA cycles can be identified and testing started on changes that can lead to improvement. 3. Time lines can be constructed to give guidance to the team. 4. Larger projects can be scoped down using the Tree Diagram. Charters can be used to manage these larger projects with sub-charters or improvement plans. Using the Tree Diagram to Improve Complex Projects © API/September 2006 7 References Bowles, John. The Society of Automotive Engineering’s Failure Modes and Effects Analysis (Proposed Document) 1996. Juran, J.M., Gryna, Frank. Juran’s Quality Control Handbook Fourth Edition McGraw-Hill Book Company. 1988. New York: Mizuno, S., ed. Management for Quality Improvement: The 7 New QC Tools. MA: Productivity Press, Inc. 1988. Cambridge, Shiba, Shoji, Alan Graham, David Walden. A New American TQM: Four Practical Revolutions in Management. Portland, OR: Productivity Press. 1993. Wilson, Paul F., Larry D. Dell, Gaylord F. Anderson. Root Cause Analysis: A Total Quality Management. Milwaukee: ASQC Quality Press. 1993. Tool for Exercises 1. Consider a recent problem in your organization and develop a problem tree diagram. 2. Select a work objective that is currently a challenge and develop a planning type tree diagram. Using the Tree Diagram to Improve Complex Projects © API/September 2006 8 Appendix: Healthcare Examples of the Tree Diagram Care of Heart Failure Patients at XYZ Hospital Describe Project: (check one) _X_ Redesign existing Process(es), product or service ___ Design new process(es), Product or service ___ Improve the system as a Whole (mainstay, drivers & support processes) Improvement Objectives / Measures 100% of patients will have standardized order set used Questions to Answer How can we automate this with Excellian (computerized documentation system) How do we get this on the chart for every patient? B17: Develop computerized order set for HF patients E41/H59/B18:Work with Care Coordinators to put paper order set on chart and follow up to ensure it is completed How do we ensure providers use it and fill it in on each patient? 99% of pts will receive LVF assessment and ACEI/ARB’s as appropriate How can we assess if LVF assessment is planned for after DC or done prior to adm? H59/B18/B19: Include check boxes on order set that indicate these elements How will we know if ACEI/ARB was considered but contraindicated? Brief Description: (include description above) To improve the care provided to heart failure patients by including evidenced based interventions thereby decreasing readmission rates Change Concept/ Ideas 99% of pts will receive smoking cessation advice Is smoking history getting consistently assessed on admission? 99% of pts will receive comprehensive dc instructions How do we ensure all providers know what elements need to be included in dc instructions? How do providers document instructions given? Decrease ALOS What other factors influence ALOS beyond 4 core measure? B17: Make this a required field on admission profile and/or on order set H59/B18/B19: Include check boxes on order set that indicate these elements G51: Create a standard HF pathway Do these pts follow a typical path? Prepared by: Martha Frederickson Are there commonalities among pts with targeted LOS? Using the Tree Diagram to Improve Complex Projects © API/September 2006 9 E41/E40: Have Case managers follow HF patients while hospitalized Improvement Objectives Measures Describe Project: (check one) ___ Redesign existing Process(es), product or service __Design new process(es), product or service ___ Improve the system as a Whole (mainstay, drivers & support processes) Brief Description: (include description above) To decrease the risk and occurrence of post-op respiratory complications after elective general and vascular surgery in at-risk patients by initiating a preop pulmonary assessment and conditioning/rehabilitation program. This will be achieved by: Physician engagement – identify patient candidates well in advance of surgery date Development of a Pulmonary Rehab Express program for preop patients Availability of documentation of rehab parameters upon arrival on day of surgery Develop a standardized pre-op pulmonary rehab referral form and process to begin use in physician office through Pulm Rehab to Pre-Surgical Screening (PSS). Include ICD9 codes for insurance coverage. Develop Rehab Express program to accommodate elective general and vascular surgery patients with pre-op chronic respiratory risks (optimal length of time for conditioning is projected at 2 weeks) Develop procedure and educate surgeons, Anesth., Pulmonologists, office staff, PSS and patients (develop educational materials). Develop a process and provide pre- and post-rehab conditioning parameters for Anesthesiology at time of patient admission for surgery. Decrease post-op pulmonary complications including dyspnea, prolonged ventilator dependency and pneumonia. Potential additional measures: decrease post-op length of stay, cost per case and readmission for respiratory conditions. Category and continuous data on patients referred, rehab program completed and pulmonary status measure improvement. Questions to Answer Change Concept/ Ideas Can Pulmonary Rehab handle added volume? Do they have a program already or one that could be adapted to this? Are there forms that could be used/modified for this program? Will surgeons agree with the need for pre-op pulmonary conditioning and refer in advance of boarded elective surgery? What’s the degree of belief that this program is needed by surgeons, anesthesiologists & pulmonologists? Will busy and different office staffs and PSS cooperate and support this new initiative? Teach office staff, Pulm Rehab and PSS the process. Teach office staff, Pulm Rehab and PSS the process. Will this program be cost effective? What happens if a patient’s insurance will not cover or the patient does not have insurance? What if there is less than 2 weeks before surgery? Standardization – create a formal process (51) Develop operational definitions (53) Conduct training (31) Will Anesthesia utilize pulmonary rehab information, find it of value? What if there is less than 2 weeks before the surgery? Will patients agree to the program, stick with it once it is started? How will we attribute complications to pre-op pulmonary risk? Will office, Pulm Rehab and PSS staff support ongoing evaluation & improvement of the process? Pilot the whole process on one or two patients to work out the bugs. Include office, Pulmonary Rehab and PSS stgff in evaluation and revision of process. Will timing of NSQIP data be timely enough to monitor the process? Will there be enough patients referred in order to evaluate and do statistical analysis? 9/8/2006 Prepared by: Laura DeSantis © API/September 2006 10 1. Pulm Rehab capacity/program evaluation PDSA 2. 4/12/2006 Surgery QA Committeesurgeon buy-in PDSA 3. 4/28/06 first patient referral (elective AAA) 5/2 assessment completed, 5/5 PR Express began PDSA 4. PDSA Engage/use the physicians and office staff in ongoing evaluation/process improvement. Using the Tree Diagram to Improve Complex Projects Develop alliance/cooperat ive relationships (37) Coach customers to use product / service (39) Standardization (51) Use a coordinator (41) Conduct training (31) Enable access to information PDSA (gant) Use proper 5. PDSA