113 Sand & Fill (RRC)-JOB PROCEDURE

advertisement

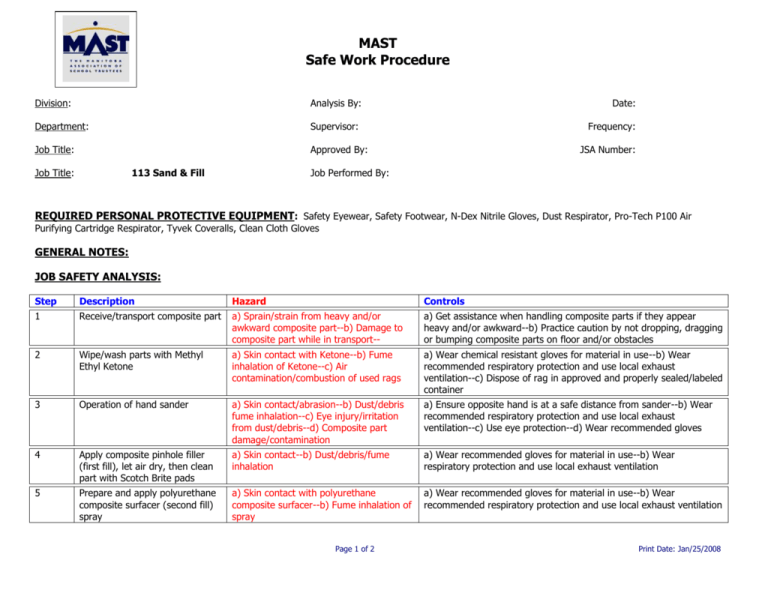

MAST Safe Work Procedure Division: Analysis By: Department: Supervisor: Job Title: Approved By: Job Title: 113 Sand & Fill Date: Frequency: JSA Number: Job Performed By: REQUIRED PERSONAL PROTECTIVE EQUIPMENT: Safety Eyewear, Safety Footwear, N-Dex Nitrile Gloves, Dust Respirator, Pro-Tech P100 Air Purifying Cartridge Respirator, Tyvek Coveralls, Clean Cloth Gloves GENERAL NOTES: JOB SAFETY ANALYSIS: Step Description Hazard Controls 1 Receive/transport composite part a) Sprain/strain from heavy and/or awkward composite part--b) Damage to composite part while in transport-- a) Get assistance when handling composite parts if they appear heavy and/or awkward--b) Practice caution by not dropping, dragging or bumping composite parts on floor and/or obstacles 2 Wipe/wash parts with Methyl Ethyl Ketone a) Skin contact with Ketone--b) Fume inhalation of Ketone--c) Air contamination/combustion of used rags a) Wear chemical resistant gloves for material in use--b) Wear recommended respiratory protection and use local exhaust ventilation--c) Dispose of rag in approved and properly sealed/labeled container 3 Operation of hand sander a) Skin contact/abrasion--b) Dust/debris fume inhalation--c) Eye injury/irritation from dust/debris--d) Composite part damage/contamination a) Ensure opposite hand is at a safe distance from sander--b) Wear recommended respiratory protection and use local exhaust ventilation--c) Use eye protection--d) Wear recommended gloves 4 Apply composite pinhole filler (first fill), let air dry, then clean part with Scotch Brite pads a) Skin contact--b) Dust/debris/fume inhalation a) Wear recommended gloves for material in use--b) Wear respiratory protection and use local exhaust ventilation 5 Prepare and apply polyurethane composite surfacer (second fill) spray a) Skin contact with polyurethane composite surfacer--b) Fume inhalation of spray a) Wear recommended gloves for material in use--b) Wear recommended respiratory protection and use local exhaust ventilation Page 1 of 2 Print Date: Jan/25/2008 6 Transport composite parts to/from heat bank a) Heat exposure while in heat bank--b) Strain/sprain from heavy and/or awkward composite parts a) Do not spend an extended period in heat bank and have an observer--b) Get assistance when handling composite parts that appear heavy and/or awkward 7 Final sand of composite part before painting a) Composite part damage/contamination--b) Dust/debris inhalation a) Wear recommended cloth gloves--b) Wear recommended respiratory protection and use local exhaust ventilation AUTHORIZED EMPLOYEE INFORMATION: ID NUMBER: LAST NAME: FIRST NAME: REMARKS: JOB HISTORY INFORMATION: DATE: REMARKS: Approval Signature: Date: Page 2 of 2 Print Date: Jan/25/2008