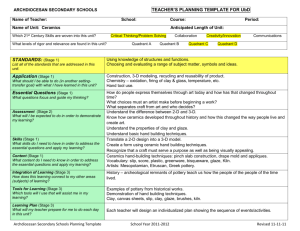

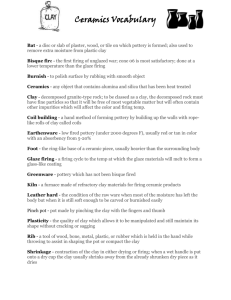

ceramics 1b vocabulary

advertisement

CERAMICS 2 VOCABULARY Ms. Brown STAGES OF CLAY 1. . green ware: any clayware which has not been bisque fired plastic: clay which is easily manipulated without sagging or cracking leather hard: the state of clay when most of the moisture has left but the clay is still plastic enough to be joined or carved. bone dry: clay which contains no moisture. Bone dry ware is ready for firing. 2. bisque ware: unglazed ware fired to a temperature sufficient to harden and mature the body. 3. glaze ware: clay which has been bisque fired and refired after applying glaze. HANDBUILDING TECHNIQUES 1. pinching: the process of opening a ball of clay in your palm by pinching the wall with your thumb and forefinger to form a bowl. Commonly used with two pinch pots joined at the rims for hollow sculptural forms. 2. coiling: rolling snake like coils and joining them together by scoring or blending. Used to create organic forms. 3. slab: slabs are formed with dowels and a rolling pin, cut to size and joined by scoring or blending. Commonly used for geometric forms. TERMS 1. 2. 3. 4. 5. 6. 7. bisque fire: preliminary firing to harden the body prior to glazing brushing: most common technique for applying glaze. burnishing: rubbing the green ware with a spoon to create a shiny surface centering: positioning the clay on the wheel so that the clay is in position for throwing coiling: a hand building method of forming pottery with rope like coils combing: a method of decoration developed by dragging a coarse comb or other tools critique: the process of evaluating artwork by giving constructive feedback in order to help the artist improve 8. dipping: glazing pottery by immersing it in a large pan or vat of glaze. 9. dry foot: to clean the bottom of a glazed piece before firing. 10. foot: the ring like base of a ceramic piece, usually formed by tooling the excess clay. 11. form: element of art used to describe 3 dimensional work 12. functional ceramics: ceramics that serves a purpose. example: vase 13. glaze: a liquid suspension of finely ground minerals that is applied by brushing, pouring, or spraying on the surface of bisque-fired ceramic were. After drying the ware is fired to the temperature at which the glaze ingredient will melt together to form a glassy surface coating. 14. glaze fire: a firing cycle to the temperature at which the glaze materials will melt to form a glasslike surface coating. This is usually at the point of maximum body maturity and it is considerably higher than the bisque fire 15. kiln: a furnace made of refractory clay materials for firing ceramic products. 16. kiln furniture: refractory shelves and posts used to support ceramic ware inside the kiln 17. kiln wash: a protective coating of refractory materials applied to the surface of the shelves and the kiln floor to prevent excess glaze from fusing the ware to the shelves 18. matte glaze: a non-shiny glaze usually developed by the addition of barium carbonate or alumina. 19. maturity: the point during firing when bisque ware reaches maximum non-porosity and hardness or when the glaze fuses completely developing a strong bond with the body, a stable structure, maximum resistance to abrasion, and a pleasant surface structure. 20. molds: a form on which clay is laid or pressed against, giving it shape or a box usually made of plaster of paris, containing a hollow negative shape. The positive form is made by pouring either wet plaster or slip into this hollow. 21. casting (slip casting): a reproductive process of forming clay objects by pouring a clay slip into a hollow plaster mold and allowing it to remain long enough for a layer of clay to thicken on the mold wall. After hardening, the clay object is removed. 22. plaster of paris: hydrate of calcium sulfate, made by calcimine gypsum. It hardens after being mixed with water. Because it absorbs moisture and can be cut and shaped easily, it is used in ceramics for drying and throwing bats, as well as for molds and casting work. 23. plasticity: the quality of clay that allows it to be manipulated and still maintains its shape without cracking or sagging 24. pouring: a technique for applying glaze, especially to the interior of a vessel 25. pug mill: a machine for mixing plastic clay. 26. sgrafitto: method of decorating pottery by painting colored slip or underglaze on greenware and then carving to the clay below 27. score,slip, and blend: the process for joining two pieces of clay together 28. slip: clay in liquid suspension. 29. throwing: forming plastic clay on a potter’s wheel. 30. turning or tooling: trimming the walls and foot of a pot on the wheel while the clay is leather hard. 31. underglaze: colored decoration applied to the bisque ware before the glaze coating 32. ware: pottery or porcelain in the raw, bisque or glazed state. 33. wax resist: a method of decorating pottery by brushing on melted wax or drawing on pottery with wax crayon. The wax acts as a resist by preventing glaze or stain to adhere to the coated areas. Wax can be applied raw or bisque ware, over or between two layers of glaze. 34. wedging: kneading plastic clay with the heels of the hands in a rocking spiral motion to force out trapped air pockets and develop a uniform texture. Process Clay thicker than 1 inch must be hollowed out before firing or it will break in the kiln. Clay must be bone dry before firing or it will break in the kiln. Trapped air must have a way out (example: a gourd with a hole) or it will break in the kiln Ceramics that dries too quickly may crack Glaze should by mixed thoroughly before applying. Glaze not mixed will not perform as intended. Texture can be added to green ware, not bisque ware. Pinholing or pitting is a defect that leaves small holes in the glaze. Usually from underfiring. Crawling is when the glaze separates and leaves the clay exposed. Usually this happens if the ceramic piece is dusty or dirty. Another cause is if the glaze is too thick. Warping is the distortion of a pot during drying because of uneven wall thickness, or during firing when the kiln does not heat uniformly. Shrinkage is the term used to describe the clay’s reduction in size as it dries and during the firing process. Shrinkage factor of 15% means the clay piece will be 15% smaller when it is finished.