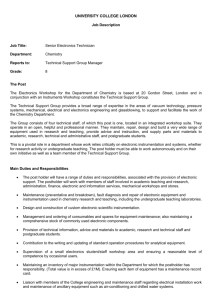

Specialist Technician - Instrumentation Job Description

advertisement

JOB DESCRIPTION – SPECIALIST TECHNICIAN - INSTRUMENTATION DEPARTMENT – ENERGY OPERATIONS 1. PURPOSE OF JOB To maintain and develop all Instrumentation and Control equipment associated with an assigned area of plant, safely and economically, under the direction of the Maintenance Engineer and Electrical Asset Manager in order to provide the required level of plant performance. 2. PRINICPLE ACCOUNTABILITIES 2.1 Ensure the availability of the assigned area of plant is kept to the required standard and be recognised as the first line of call in the even of plant failure. This includes the departmental ‘best endeavours’ call out system. Plan programmed maintenance and arising jobs to minimise the loss of productive time, make best use of engineering resources and minimise costs prioritising the needs of the 4 Manufacturing areas using work notification and planning / scheduling tools. Ensure all aspects of engineering activities are carried out in a safe manner and comply with all the relevant Engineering and health and safety legislation including MOC. Carry out isolation/immobilisation of equipment and issue necessary permits, within your area of expertise. Inspect equipment, collect data, record and analyse the current condition of the assigned plant and monitor its performance trends to identify weaknesses and irregularities so as to determine correct engineering priorities in order to optimise production and maintenance schedules. Assist in establishing inspection standards and recommend changes to maintenance procedures and equipment design to improve plant and performance. Organise and supervise both Corus and contractor resources within the assigned area to execute maintenance activities to prescribed procedures and standards. Maintain information systems (SAP & PCM) and drawings to ensure that all details of equipment condition and maintenance work are up to date and accurate. Arrange for spares, tools and labour to be available to meet the requirements of each repair and maintenance activity. Organise the repair and manufacture of spares items through both internal and external means to ensure they meet the desired engineering standards. Ensure that the production availability is maintained by personally executing repairs to the limit of competence to enable equipment to be brought back into use as quickly as possible. To be generally involved in the installation and commissioning of new plant and equipment by way of training and familiarisation to ensure successful operation of new plant and transition from old. 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 3. VISION/CONTEXT The role of the Specialist Technician is built on the principle of equipment ownership and is regarded as being the equipment expert within the process area. This position requires the job holder to liaise closely with engineers of all disciplines and manufacturing personnel with the common objective of ensuring maximum production and maintenance availability. Because of manning levels within Energy Operations and the lack of high level shift support, areas of ownership are much less defined hence assistance in all areas is frequently required. 4. 5. CONTACTS Engineering Staff To discuss problems and to organise the execution of engineering activities. Shift Manufacturing Personnel To ensure that issues affecting operations are identified and dealt with. Operational Managers To discuss plant problems and access for Maintenance and to priorities efforts across the plant areas. Equipment Manufactures & Suppliers To liaise on technical matters relating to the supply and manufacture or repair of equipment, ensuring it meets the desired standards. Contractors To schedule work and supervise its execution. Internal Technical Services To discuss the performance of equipment and the possibilities of making improvements in its performance. KNOWLEDGE AND EXPERIENCE The job holder will be qualified to BTEC National Level or equivalent with a full understanding of the Instrumentation and Control discipline. Experience of Boiler Controls and / or Large Rotating Machinery would be an advantage, but is not essential The abilities to write technical reports, prepare design specification, analyse equipment performance, diagnose faults and exercise sound man management skills are essential. A working knowledge of current relevant Engineering legislation is required (Particularly relating to Safety Related Control Systems and DSEAR). The job holder must be self motivated, innovative and have, or be capable of developing a detailed knowledge of the plant and equipment in the assigned area. Because of the widespread nature of the Energy operations department a full driving licence is required.