Acid Detergent Lignin

advertisement

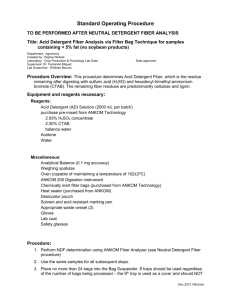

Standard Operating Procedure TO BE PERFORMED AFTER ACID DETERGENT FIBER ANALYSIS Title: Acid Detergent Lignin Analysis via Beaker Technique with Ashing Department: Agronomy Created by: Virginia Nichols Laboratory: Crop Production & Physiology Lab Suite Supervisor: Dr. Fernando Miguez Lab Supervisor: Whitney Bouma Date approved: Procedure Overview: This procedure determines Acid Detergent Lignin, which is the residue remaining after digesting with concentrated sulfuric acid (H2SO4). The remaining fiber residues are predominantly cellulose and lignin. Equipment and reagents necessary: Reagents: Sulfuric Acid (72% by weight, purchased pre-standardized from ANKOM Technology) Acetone Miscellaneous: 2L and 3L beaker Oven @ 105 ˚C Waste container for acid waste MoistureStop weigh pouch Analytical balance Crucibles Muffle furnace, Trish Patrick’s lab Litmus paper for measuring pH Procedure: 1. Perform NDF determination using ANKOM Fiber Analyzer (see Neutral Detergent Fiber procedure) 2. Perform ADF determination using ANKOM Fiber Analyzer (see Acid Detergent Fiber procedure) 3. IMPORTANT: Ensure bags are completely dry and are at ambient temperature before adding acid. If moisture is present in the bags, heat generated by the sulfuric acid – water reaction will adversely affect the results. 4. Place dried bags into 3L beaker and add sufficient quantity (~250 ml) of 72% H2SO4 to cover bags. 5. Place 2L beaker inside 3L beaker to keep bags submerged. Agitate bags at start and at 30 minute intervals by gently pushing and lifting 2L beaker ~30 times. 6. After 3 hours pour off 72% H2SO4 into waste container and rinse bags with tap water to remove all acid. Repeat rinses until pH is neutral, confirmed using Litmus paper. Rinse with ~250 ml acetone for 3 minutes to remove water. Allow acetone to evaporate. 7. DO NOT place bags in oven until acetone is completely evaporated, as acetone is extremely flammable. 8. Complete drying in oven at 105°C for 2-4 hours. Dec 2012 VNichols 9. Remove bags from oven and place directly in MoistureStop weigh pouch, flattening to remove air. 10. Cool to ambient temperature and weigh (W 3). 11. Ash entire bag in pre-weighed crucible (30-50 ml) at 525°C for 3 hours or until C-free. Cool and calculate weight loss (W 4). Calculate blank bag ash correction (C2) using weight loss upon ignition of a blank bag sequentially run through ADF and lignin steps. Calculations ADL (as received basis) =[ [(W3 – (W1 x C1))] / W2 ] x 100 ADLDM (DM basis) =[ [(W3 – (W1 x C1))] / (W2 x DM) ] x 100 ADLOM (as received basis) =[ [(W4 – (W1 x C2))] / (W2 x DM)] x 100 W1 = bag tare weight W2 = sample weight W3 = dried weight of bag with fiber after extraction process W4 = weight of organic matter (loss of weight on ignition of bag and fiber residue) C1 = blank bag correction (final oven weight of blank bag) / (original blank bag weight) C2 = Ash corrected blank bag (loss of weight on ignition of bag) / (original blank bag weight) Personal Protective Equipment / Engineering Controls: Nitrile gloves Safety glasses Face shield Dust mask Latex gloves Splash goggles Lab coat Fume hood Neoprene gloves Vented goggles Apron Biosafety cabinet Insulated gloves Eye wash station Safety shower Respirator Note: Open-toed and heeled shoes are NOT allowed. Other Control Measures: Handling & Storage Precautions: Sulfuric Acid, 72%: Use with adequate ventilation, wash hands and clothing thoroughly after handling. Store in a cool, dry, well-ventilated area away from incompatible substances. Never add water to this solution – always add acid slowly and in small amounts to water. Acetone: Use with adequate ventilation, wash hands and clothing thoroughly after handling. Store in a cool, dry, well-ventilated area away from incompatible substances and away from ignition sources. Waste Disposal Procedures: Unless EH&S specifically instructs otherwise, all chemical/reagent waste (including excess solutions) must be placed in an appropriately labeled hazardous waste container for EH&S disposal. Compatible substances may be combined into one waste container. Dec 2012 VNichols Spill/Release Containment and Clean Up/Decontamination Procedures: Sulfuric Acid, 72%: Soak up with an inert absorbent material. Rinse area with water. Acetone: Remove all sources of ignition and provide adequate ventilation. Soak up with an inert absorbent material. Health & Safety Summary for Required Reagents: Sulfuric Acid, 72% is a stable, non-flammable, corrosive substance. It should not be heated above 250°C. Use extreme caution not to allow solution to contact skin. It is a moderate health risk and a severe contact risk. DO NOT add water to this solution. Acetone is flammable – avoid excessive temperatures, heat, sparks, open flame, and other sources of ignition. It has a very high vapor pressure, and should therefore only be used in well-ventilated areas. C a r c i n o g e n T e r a t o g e n C o r r o s i v e T o x i c I r r i t a n t Chemical name Sulfuric acid, 72% Acetone S e n s i t i z e r H i g h l y C o m b u s t i b l e T o x i c Target Organ(s) X X Eyes, skin, teeth and respiratory tract. X Central system C o m p r e s s e d E x p l o s i v e F l a m m a b l e G a s nervous O r g a n i c P e r o x i d e s O x i d i z e r P y r o p h o r i c U n s t a b l e W a t e r R e a c t i v e X X H e a l t h F l a m m a b i l i t y R e a c t i v i t y Alkalies, amines, anhydrides, combustibles, organics, oxidizers, powdered metals. 3 0 2 Chloroform, chromic anhydride, hydrogen peroxide, nitric compounds, acids, strong oxidizers, alkalies. 1 3 0 Incompatibilities The above summary consists of guidelines for proper handling & disposal of chemicals used in this procedure. You must read and understand the contents of the entire MSDS(s) before starting this procedure. References: ANKOM Procedures, available through ANKOM website. Sulfuric Acid, 72% MSDS, available through ANKOM website. Acetone MSDS, available through ANKOM website Dec 2012 VNichols